| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction:

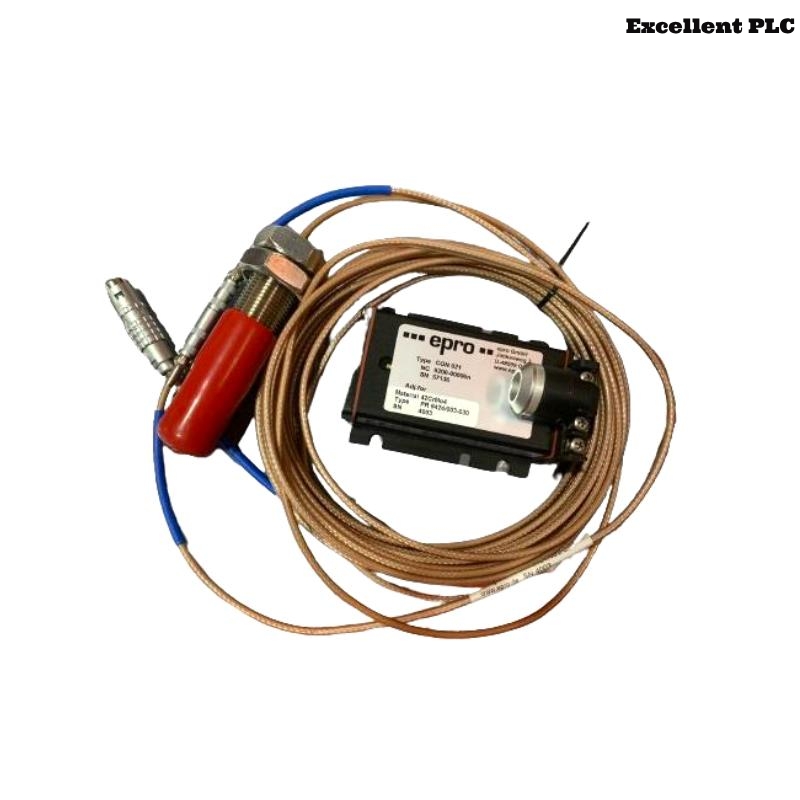

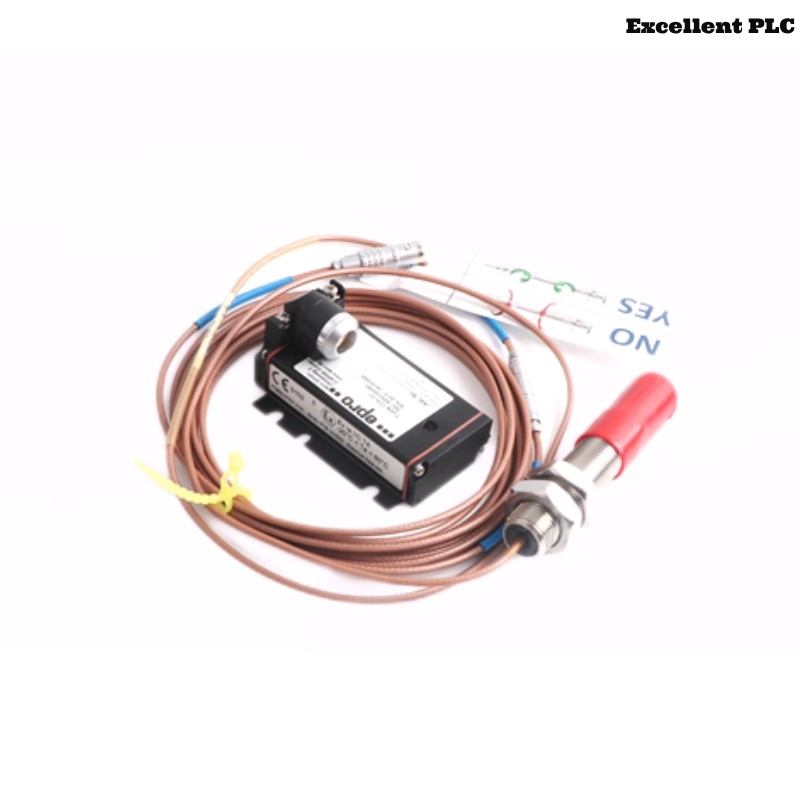

The Epro PR6424/010-131+CON031 16mm Eddy Current Sensor is a high-performance measurement device designed for precision measurement and monitoring of displacement, position, and vibration in industrial applications. This sensor uses the principle of eddy current technology to detect the position or movement of a conductive target. The device is commonly used for non-contact measurement applications, providing high accuracy, fast response times, and long-term stability.

The Epro PR6424/010-131+CON031 sensor integrates seamlessly with control systems in industrial environments, where reliability and precision are paramount. Its robust design ensures it can perform in harsh conditions, such as high-temperature environments, making it ideal for use in machinery, motors, turbines, and other critical systems that require continuous monitoring and measurement.

Product Parameters:

Here are the detailed specifications for the Epro PR6424/010-131+CON031 16mm Eddy Current Sensor:

| Parameter | Description |

|---|---|

| Sensor Type | Eddy Current Sensor |

| Sensor Head Diameter | 16 mm |

| Measurement Principle | Eddy Current Technology (Non-contact) |

| Target Material | Conductive materials (e.g., metals) |

| Measurement Accuracy | ±0.5% of Full Scale |

| Resolution | 0.001 mm |

| Output Type | Analog (0-10V, 4-20mA) |

| Frequency Response | Up to 50 kHz |

| Operating Temperature Range | -40°C to +85°C |

| Power Supply | 24 VDC ±10% |

| Mounting Type | Flange or bracket mounting |

| Protection Class | IP67 |

| Weight | 0.32 kg |

| Connection Type | M12 Connector |

| Signal Output Cable Length | 2 meters (standard) |

| Certifications | CE, UL, RoHS |

Applications:

The Epro PR6424/010-131+CON031 16mm Eddy Current Sensor is ideal for a variety of applications where precise, non-contact measurement of position, displacement, or vibration is required. Some of the key applications include:

-

Motor and Turbine Monitoring: Used in rotating machinery such as motors and turbines, where accurate measurement of shaft displacement and vibration is critical for maintenance and safety.

-

Position Measurement: The sensor is ideal for measuring the position of moving parts in industrial systems, such as linear actuators, conveyors, or robotic arms.

-

Vibration Monitoring: In critical systems such as pumps and compressors, the sensor can monitor vibrations to detect early signs of mechanical wear or failure, helping to prevent costly downtime.

-

Machine Monitoring: The sensor is extensively used for condition monitoring of machinery and industrial equipment, where accurate displacement data helps optimize performance and reduce maintenance costs.

-

Test and Measurement Systems: Often utilized in laboratory and test environments where precise displacement measurement is required for scientific experiments, material testing, and product development.

-

Aerospace: In the aerospace industry, this sensor can be used for non-contact measurement of components such as actuators, control surfaces, and turbine blades.

Advantages:

-

High Precision and Accuracy: The Epro PR6424/010-131+CON031 sensor provides a measurement accuracy of ±0.5% of full scale, making it highly reliable for precise position and displacement measurements.

-

Non-contact Measurement: This sensor operates on the principle of eddy current technology, allowing it to provide measurements without physical contact with the target. This significantly reduces wear and tear on both the sensor and the object being measured.

-

Wide Temperature Range: The sensor is designed to operate effectively in extreme temperature conditions, ranging from -40°C to +85°C, making it suitable for industrial applications in challenging environments.

-

Fast Response Time: With a frequency response of up to 50 kHz, the sensor provides rapid measurements, which is essential in applications that require real-time monitoring, such as vibration detection and motor speed measurements.

-

Compact and Robust Design: With a compact size and a protective IP67 rating, the sensor is built to withstand harsh industrial conditions, including exposure to dust, moisture, and mechanical stress.

-

Versatile Output Options: The sensor offers multiple output options, including analog signals (0-10V, 4-20mA), providing flexibility for integration into various control and monitoring systems.

-

Easy Installation: The sensor comes with standard mounting options (flange or bracket) and an M12 connector for easy integration with existing systems.

-

Long-term Stability: The eddy current technology used in this sensor ensures long-term stability and reliability, with minimal drift over time, even under continuous use.

-

Compact Footprint: Its compact size and lightweight design make it easy to install in space-constrained applications, without compromising on performance.

-

Highly Durable: The sensor’s construction ensures durability, even in harsh industrial environments, ensuring a long lifespan with minimal maintenance.

Frequently Asked Questions (FAQ):

-

What is the sensing range of the Epro PR6424/010-131+CON031 sensor?

-

The sensing range is 16 mm.

-

-

What materials can be detected by this sensor?

-

The sensor works with conductive materials, such as metals.

-

-

What is the accuracy of the sensor?

-

The sensor has an accuracy of ±0.5% of full scale.

-

-

What is the operating temperature range of the sensor?

-

The sensor operates within the temperature range of -40°C to +85°C.

-

-

What is the power supply requirement for this sensor?

-

The sensor requires a 24 VDC power supply with a tolerance of ±10%.

-

-

How is the sensor mounted?

-

The sensor can be mounted using either a flange or bracket mounting type.

-

-

What types of output signals are available from the sensor?

-

The sensor provides analog output signals of 0-10V or 4-20mA.

-

-

Is the sensor resistant to harsh environmental conditions?

-

Yes, the sensor has an IP67 rating, making it dustproof and waterproof, suitable for harsh environments.

-

-

What is the typical weight of the sensor?

-

The sensor weighs 0.32 kg.

-

-

What type of connector does the sensor use?

-

The sensor uses an M12 connector for signal output.

-

Recommended Related Models:

Here are 6 models related to the Epro PR6424/010-131+CON031 16mm Eddy Current Sensor, offering similar functionality or enhanced features:

| Model | Description | Key Features |

|---|---|---|

| Epro PR6424/010-131+CON030 | 16mm Eddy Current Sensor | Similar functionality with different connection types |

| Epro PR6424/010-131+CON032 | High-frequency Eddy Current Sensor | Higher frequency response for more demanding applications |

| Epro PR6424/011-131+CON031 | 16mm Eddy Current Sensor with extended range | Extended measurement range with the same size |

| Epro PR6424/010-132+CON031 | 16mm Eddy Current Sensor with integrated temperature measurement | Measures both position and temperature |

| Epro PR6424/011-132+CON032 | High-precision Eddy Current Sensor | Improved accuracy and signal output flexibility |

| Epro PR6424/012-131+CON031 | Dual-output 16mm Eddy Current Sensor | Dual analog output for enhanced system integration |

Popular Epro Models:

Below are 6 popular models from Epro that are widely used in industrial applications for similar or complementary measurement tasks:

| Model | Description | Key Features |

|---|---|---|

| Epro PR6423/010-101 | 10mm Eddy Current Sensor | Compact sensor for tight spaces and small-scale applications |

| Epro PR6424/010-132 | 16mm Eddy Current Sensor with extended range | For high-precision applications in industrial machinery |

| Epro PR6424/012-132 | Dual-output 16mm Eddy Current Sensor | Provides dual analog outputs for versatile systems |

| Epro PR6423/011-102 | High-speed Eddy Current Sensor | High-frequency response for real-time monitoring |

| Epro PR6423/010-102 | Small-form factor Eddy Current Sensor | Ideal for compact and lightweight applications |

| Epro PR6424/010-130 | Standard 16mm Eddy Current Sensor | Robust design for industrial environments |

Excellent PLC

Excellent PLC