| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

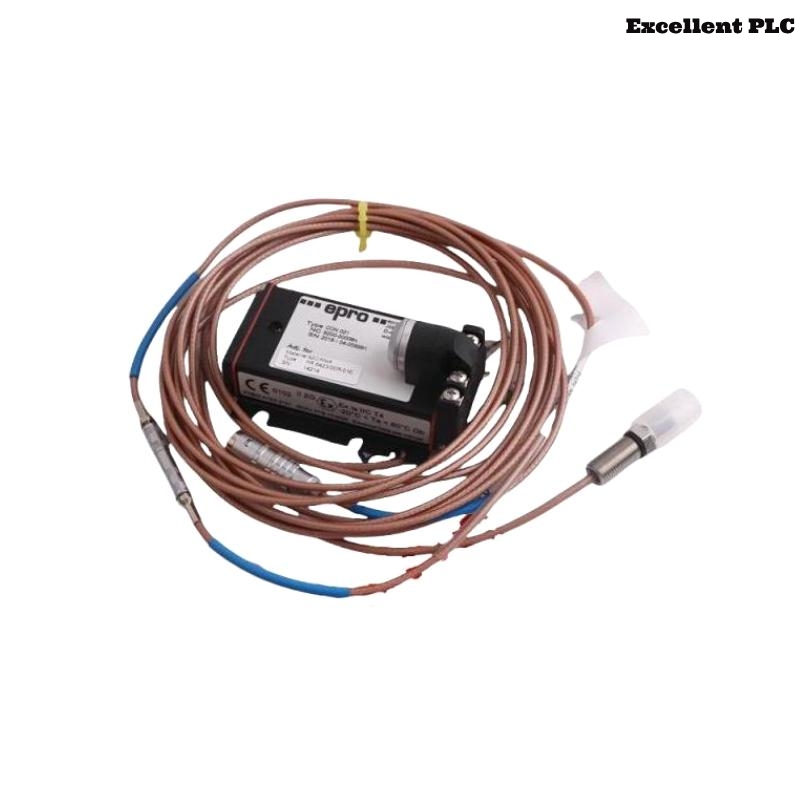

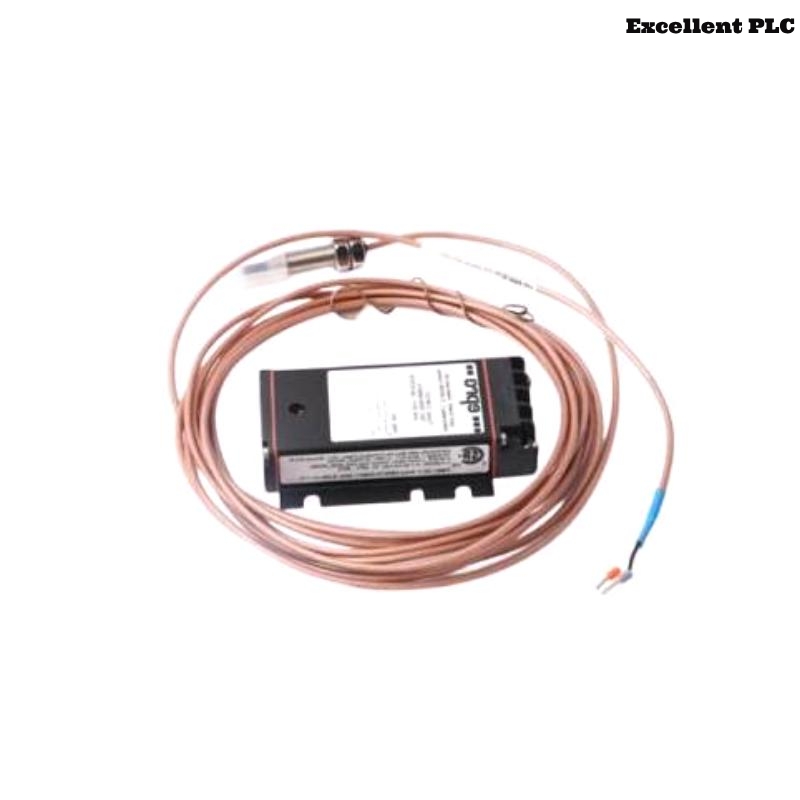

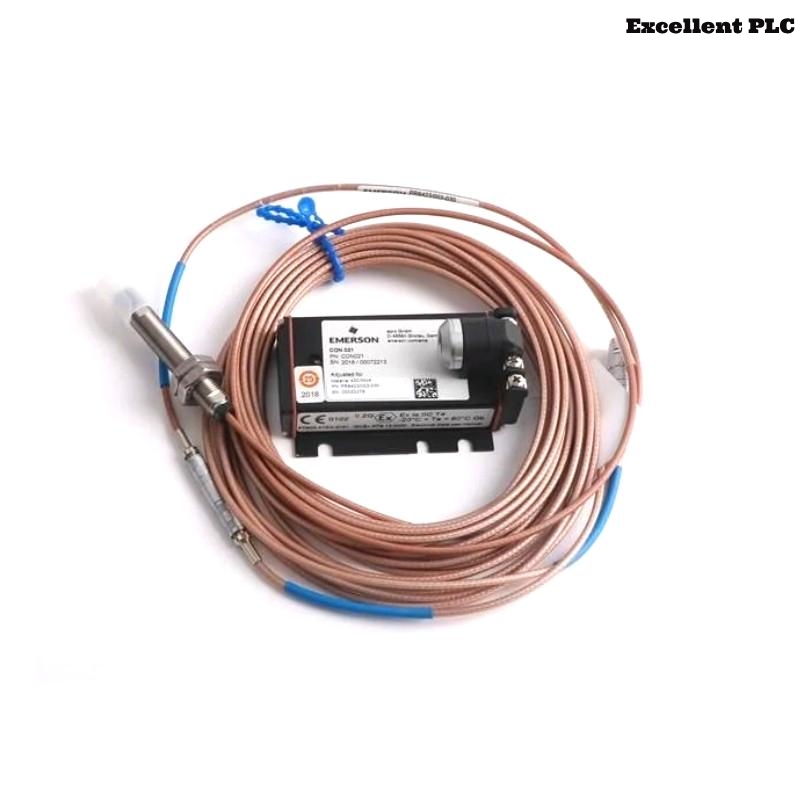

The Epro PR6424/012-000 is a robust, non-contact eddy current proximity sensor designed to measure shaft displacement, vibration, and axial position in industrial rotating machinery. Developed by EPRO (now under Emerson), this model features a 16 mm diameter probe and is intended for use in conjunction with the CON011 converter, making it a core component of Epro’s machinery condition monitoring and protection systems.

Engineered to perform under extreme conditions, the PR6424/012-000 offers exceptional stability, linear output, and resistance to temperature fluctuations, oil ingress, and electrical noise. The sensor plays a vital role in machinery protection systems compliant with API 670, especially in turbomachinery and heavy-duty rotating equipment. This particular model is factory-calibrated and optimized for applications requiring longer sensing distances and high measurement precision.

Product Specifications

| Parameter | Description |

|---|---|

| Model | PR6424/012-000 |

| Sensor Type | Eddy Current Proximity Sensor |

| Manufacturer | EPRO / Emerson |

| Probe Diameter | 16 mm |

| Sensing Range | Typically ±2 mm (linear), total range ~4 mm |

| Sensitivity | Approx. 7.87 mV/µm (with CON011) |

| Frequency Response | DC to 10 kHz (±3 dB) |

| Target Material | Ferromagnetic (e.g., 4140 steel) |

| Mounting Thread | M14 x 1.5 |

| Cable Option | No integral cable (cable and connector are separate) |

| Operating Temperature | -35°C to +180°C (depending on accessories and mounting) |

| Environmental Protection | IP65 sensor tip (when properly installed) |

| Material (Housing) | Stainless Steel AISI 303 |

| Connector Type | For connection to CON011 converter |

| Insulation Resistance | >100 MΩ @ 500 VDC |

| System Compatibility | CON011, MMS 3000/6000 Series |

| Compliance | Meets API 670, CE, RoHS |

| Weight | 0.2 kg |

Product Applications

The PR6424/012-000 is widely adopted in critical industrial applications where accurate, non-contact measurement of dynamic shaft motion is vital. Common use cases include:

-

Steam and Gas Turbines: Monitoring radial shaft vibration and thrust position.

-

Compressors and Blowers: Vibration tracking and misalignment detection in centrifugal equipment.

-

Industrial Pumps: Monitoring shaft displacement and early detection of mechanical wear.

-

Electric Motors: Assessing unbalance and rotor position in high-speed motor applications.

-

Gearboxes: Monitoring bearing wear and gear mesh issues in rotating gear assemblies.

-

OEM Integration: Embedded in skid-mounted or custom industrial systems requiring API compliance.

Product Advantages

-

Precision Measurement: Offers stable, linear output with low drift across temperature ranges.

-

API 670 Compliance: Fully supports the standard for critical rotating machinery protection.

-

Robust Mechanical Design: Stainless steel body with high mechanical durability and long operational life.

-

Modular System Integration: Seamlessly connects with CON011 converters and Epro monitoring systems.

-

Environmental Resistance: Designed to resist oil, moisture, vibration, and electromagnetic interference.

-

Wide Temperature Range: Operates in high-temperature environments, reducing the need for special housings.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between PR6424/012-000 and PR6424/011-100?

A: Both have 16 mm probes, but differ in cable configuration and factory calibration for cable length. -

Q: Does this sensor include a cable?

A: No, PR6424/012-000 is supplied without an integral cable; a separate cable is connected to the CON011 converter. -

Q: Can I use this sensor with a third-party monitoring system?

A: It is optimized for use with EPRO CON011 and MMS systems. Integration with third-party systems may require signal adaptation. -

Q: What is the maximum temperature it can handle?

A: Up to 180°C, depending on accessories such as high-temperature cables and mounting configurations. -

Q: Is this sensor compliant with API 670?

A: Yes, it fully meets API 670 requirements for critical rotating machinery monitoring. -

Q: What types of materials can this sensor measure?

A: It is designed to measure displacement from ferromagnetic materials like steel (e.g., AISI 4140). -

Q: Is the sensor tip oil-resistant?

A: Yes, the sensor is sealed and rated IP65 at the tip, making it resistant to oil and moisture when properly installed. -

Q: What happens if I exceed the sensing range?

A: Exceeding the range can lead to inaccurate readings or signal clipping. Always install within the specified gap. -

Q: Can the sensor be used in underwater applications?

A: No, it is not rated for continuous submersion. Use with sealed housings or enclosures for such environments. -

Q: Is recalibration needed after installation?

A: No, the sensor is factory-calibrated. However, system calibration is recommended if components are replaced or relocated.

Related Models (Same Series or Application)

| Model | Description | Probe Size | Cable Option | Use Case |

|---|---|---|---|---|

| PR6424/011-100 | 16 mm probe with fixed cable (10 m) | 16 mm | Yes | Extended range, turbine use |

| PR6424/014-040 | 16 mm sensor with 4 m cable | 16 mm | Yes | Pumps and compressors |

| PR6424/010-000 | 16 mm sensor without cable | 16 mm | No | Custom integration |

| PR6424/017-030 | Side-exit sensor with 3 m cable | 16 mm | Yes | Limited clearance spaces |

| PR6424/015-100 | High-temp 10 m cable variant | 16 mm | Yes | Harsh environment |

| PR6423/002-030 | 8 mm eddy current sensor with 3 m cable | 8 mm | Yes | Compact machinery |

Popular Models from the Same Brand (EPRO / Emerson)

| Model | Description | Function | Typical Application |

|---|---|---|---|

| PR6423/005-010 | 8 mm probe with CON021 converter | Eddy Current Sensor | Medium-scale rotating machinery |

| PR6424/018-000 | 16 mm short version sensor | Eddy Current Sensor | Space-constrained installations |

| CON011 | Signal converter for PR6423/PR6424 series | Signal Processing Module | Converts probe signal to voltage |

| MMS3120/022-100 | Monitoring system for condition monitoring | Monitoring System | Machine protection systems |

| PR9268/301-000 | Velocity sensor (piezoelectric) | Vibration Sensor | Bearing condition monitoring |

| MMS6110 | Advanced machine monitoring module | Monitoring System | Vibration + process parameter logging |

Excellent PLC

Excellent PLC