| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

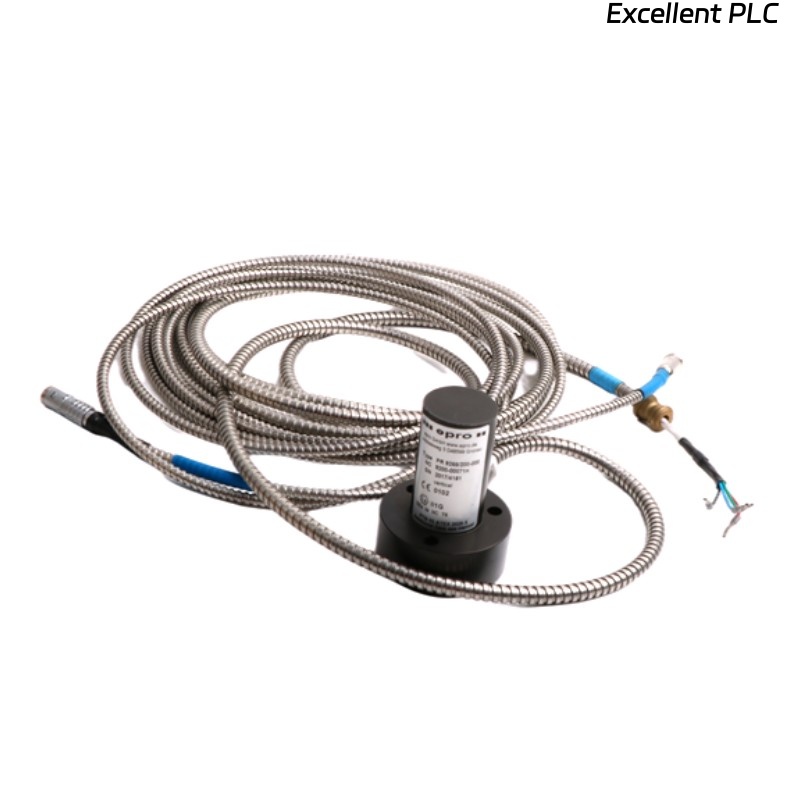

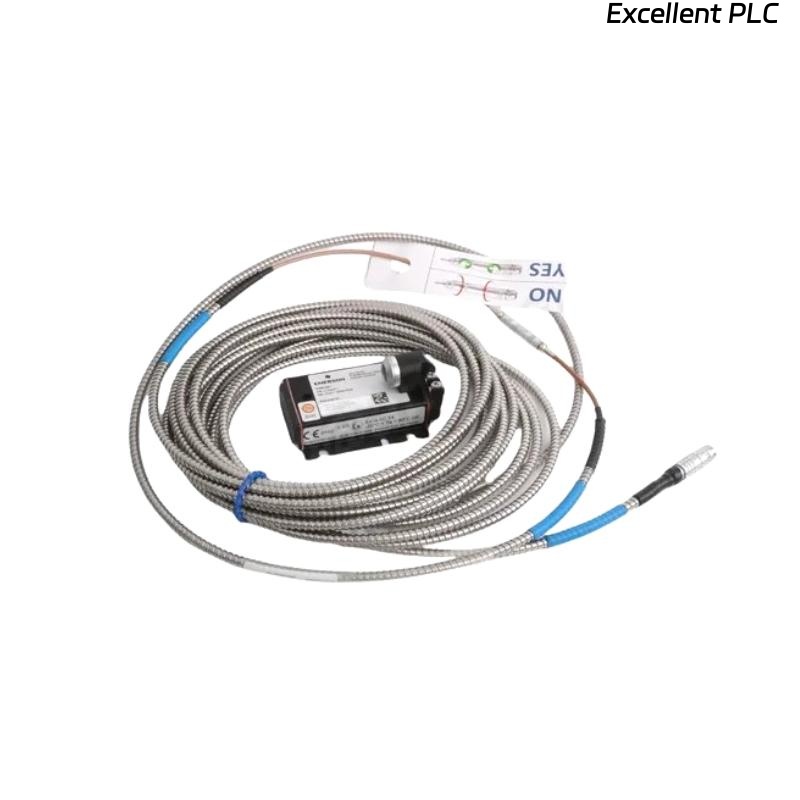

Product Overview

The Epro PR6424/013-130 + CON021 is an industrial-grade eddy current displacement sensor specifically designed for the non-contact measurement of shaft displacement and vibration in rotating machinery. This system combines the PR6424/013-130 probe, featuring a 16 mm diameter tip, with the CON021 signal converter, which delivers a standard 4–20 mA output for integration into condition monitoring or machine protection systems.

With its robust mechanical construction, high resistance to heat and vibration, and compliance with international monitoring standards such as API 670, the PR6424/013-130+CON021 is ideal for use in steam turbines, compressors, gearboxes, and other dynamic equipment where precise shaft monitoring is critical to performance and safety.

Product Specifications

| Parameter | Specification |

|---|---|

| Sensor Model | PR6424/013-130 |

| Converter Model | CON021 |

| Measurement Principle | Eddy current, non-contact displacement sensing |

| Measurement Range | 0 – 3 mm |

| Sensor Head Diameter | 16 mm |

| Output Signal (via CON021) | 4–20 mA |

| Frequency Range | 0 – 10 kHz (-3 dB) |

| Linearity Deviation | ≤ ±1% of Full Scale Output (FSO) |

| Operating Temperature (Probe) | -35°C to +180°C |

| Operating Temperature (Converter) | -35°C to +85°C |

| Storage Temperature | -40°C to +100°C |

| Pressure Resistance | Up to 100 bar |

| Probe Housing Material | Stainless Steel (AISI 316) |

| Electrical Connector | MIL-C standard or optional HT connector |

| Protection Rating | IP65 (standard), IP68 optional |

| Cable Type | Coaxial, high-temperature compatible |

| Cable Length | 5 m, 7 m, 9 m, or custom calibrated lengths |

| Compliance Standards | API 670, CE, optional ATEX/IECEx certified for hazardous zones |

| Weight | 0.32 kg |

Applications

The Epro PR6424/013-130 + CON021 sensor system is engineered for deployment in mission-critical rotating machinery, where the accurate detection of shaft position and motion is vital. Its durable, thermally stable design ensures reliable long-term operation under extreme process conditions.

Typical applications include:

-

Radial and axial shaft vibration monitoring in steam and gas turbines

-

Axial thrust detection in high-speed compressors and centrifugal machines

-

Condition monitoring of gearboxes in metallurgical and process industries

-

Bearing wear measurement in large electric motors and pumps

-

Vibration and displacement analysis in predictive maintenance programs

-

Industrial turbine protection in compliance with API 670 and ISO 10816

Applicable industries:

-

Power generation (thermal, hydro, nuclear)

-

Oil and gas refining, LNG terminals

-

Petrochemical, fertilizer, and chemical industries

-

Mining, cement, pulp & paper

-

Marine and offshore platforms

Product Advantages

-

Factory-Matched Probe and Converter Set

Ensures optimal accuracy, reduced noise, and no need for field calibration. -

Superior Thermal Stability

Performs reliably in high-temperature zones near turbines, bearings, and compressors. -

Standardized 4–20 mA Output

Compatible with a wide range of industrial controllers, DCS, and monitoring racks. -

Resistant to Harsh Environments

Stainless steel build and IP-rated sealing protect against oil, dust, and vibration. -

High Accuracy and Repeatability

Maintains measurement precision over long durations with minimal drift or hysteresis. -

Compact Footprint

Enables mounting in confined spaces and integration into dense mechanical layouts. -

International Compliance

Conforms to API 670, CE, and available in ATEX-certified versions for explosive zones. -

Long Lifecycle and Low Maintenance

Designed for continuous operation with minimal servicing requirements.

Frequently Asked Questions (FAQ)

-

What differentiates the PR6424/013-130 from the 010-130 model?

The 013-130 variant features specific calibration and configuration for installations requiring slightly longer probe lengths or enhanced mounting flexibility. -

Can the CON021 converter be mounted remotely from the sensor?

No, the converter is factory-paired with the probe and coaxial cable. The complete set must be installed together as supplied. -

Is the sensor suitable for outdoor use or exposed conditions?

Yes, with appropriate sealing and housing, the sensor can withstand wet, dusty, or high-vibration environments. -

Can I use this sensor in a hazardous area (Zone 1 or Zone 2)?

Yes, ATEX-certified versions are available for operation in hazardous areas. Please confirm before ordering. -

What is the response time of the system?

The sensor system supports fast dynamic measurements with a bandwidth up to 10 kHz. -

Does the sensor measure absolute position or vibration?

It measures absolute displacement of the shaft. When connected to monitoring modules, it can derive vibration characteristics as well. -

Can the sensor be reused on another machine after dismounting?

Technically yes, but as the probe is factory-calibrated with the cable and converter, reuse requires care to maintain calibration accuracy. -

Is the sensor field-configurable?

No. It is pre-calibrated at the factory and should not be altered in the field. -

Can the sensor be embedded inside a bearing housing?

Yes. With proper alignment and mounting, it can be embedded directly into bearing brackets or casings. -

Does the system support online condition monitoring platforms?

Absolutely. Its 4–20 mA output can be fed into online CMS systems or SCADA platforms for real-time monitoring.

Related or Same Series Models

| Model | Tip Diameter | Range | Temperature Rating | Typical Application |

|---|---|---|---|---|

| PR6424/010-130+CON021 | 16 mm | 0–3 mm | -35°C to +180°C | General-purpose displacement monitoring |

| PR6424/014-130+CON021 | 16 mm | 0–4 mm | -35°C to +180°C | Extended range version |

| PR6424/010-120+CON021 | 16 mm | 0–3 mm | -35°C to +180°C | Standard version with shorter cable |

| PR6424/012-130+CON041 | 16 mm | 0–3 mm | Up to 200°C | Higher temperature variant |

| PR6424/013-100+CON021 | 16 mm | 0–3 mm | -35°C to +180°C | Custom probe length for confined spaces |

| PR6424/01CS+CON021 | 16 mm | 0–3 mm | -35°C to +180°C | Compact sensor system for tight integration |

Popular Models from the Epro Brand

| Model | Type | Function | Notes |

|---|---|---|---|

| MMS6312 | Monitoring Module | Dual-channel monitoring of axial/radial motion | Rack-mount system, API-compliant |

| PR6423/002-030+CON021 | Eddy Current Sensor | 8 mm probe for tight space radial sensing | Compact version of the PR6424 series |

| MMS3120/022-100 | Monitoring Module | Condition monitoring, vibration signal processing | Standalone, DIN rail mountable |

| CON041 | Signal Converter | For PR6426 probes, 4–20 mA analog output | Compatible with legacy and new setups |

| PR9268/201-000 | Seismic Sensor | Measures casing velocity vibration | Suited for pumps, fans, and gearboxes |

| MMS6110 | Central Monitoring Rack | Multi-channel rack with relay and BNC outputs | Designed for turbomachinery protection systems |

Excellent PLC

Excellent PLC