| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

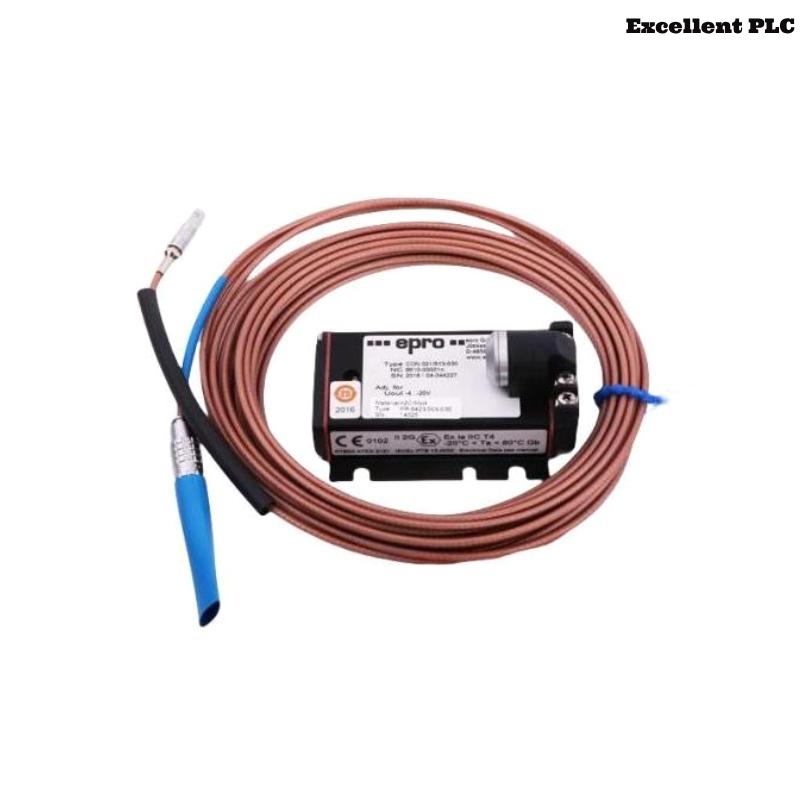

The Epro PR6424/014-040+CON021 is a precision-engineered eddy current displacement sensor designed for non-contact vibration and axial position measurement, particularly in rotating machinery such as turbines, compressors, and motors. With a 16mm sensing range, this sensor is part of Epro’s advanced PR6424 series and is paired with the CON021 converter to deliver an accurate, linear output signal suitable for integration into various monitoring and protection systems.

Based on eddy current measurement technology, the sensor detects changes in distance between the probe tip and a conductive target surface. The combination of PR6424/014-040 probe and CON021 converter ensures high sensitivity, excellent linearity, and robust performance in even the most demanding industrial conditions.

This product is used widely in predictive maintenance, vibration monitoring systems, and machinery protection solutions in sectors such as power generation, petrochemical processing, metallurgy, and other heavy industries.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Model | Epro PR6424/014-040+CON021 |

| Sensor Type | Eddy current, non-contact displacement/vibration sensor |

| Sensor Head Diameter | 16 mm |

| Target Material | Ferromagnetic or conductive materials (e.g., steel) |

| Sensitivity | Configurable via CON021 converter (typical: 4 mV/µm) |

| Output Signal | ±5 V or 0–10 V DC (via CON021) |

| Supply Voltage | 24 V DC (via CON021) |

| Frequency Response | DC to 10 kHz |

| Linearity | ≤ ±1% of full scale |

| Operating Temperature | -35°C to +180°C (sensor), -20°C to +85°C (CON021) |

| Storage Temperature | -40°C to +200°C |

| Pressure Resistance | Up to 10 bar |

| Environmental Protection | IP68 (sensor), IP65 (CON021) |

| Cable Type | Coaxial cable, length customizable (standard 5 m) |

| Housing Material | Stainless steel (probe), anodized aluminum (converter) |

| Mounting Thread | M14 x 1.5 |

| Dimensions (Sensor) | Ø16 mm x 80 mm (body only) |

| Weight | 0.32 kg |

Applications

The Epro PR6424/014-040+CON021 is used across a wide range of applications that require real-time, high-precision vibration or displacement measurements for rotating machinery. Key applications include:

-

Turbomachinery Monitoring: Critical for steam turbines, gas turbines, and hydro turbines, enabling early detection of shaft vibrations, misalignment, and mechanical wear.

-

Compressor Protection: Ensures compressors run within vibration tolerances, reducing the risk of catastrophic failure.

-

Gearbox Monitoring: Detects gear misalignment, imbalance, or lubrication issues by monitoring axial shaft movement.

-

Motor and Generator Systems: Used for both bearing vibration monitoring and shaft position tracking to avoid unplanned downtime.

-

Petrochemical Industry: Integrated into vibration monitoring systems in refineries and chemical plants to safeguard high-value rotating assets.

-

Condition-Based Maintenance (CBM): Enables operators to shift from reactive to predictive maintenance, improving machine reliability and minimizing operational costs.

-

Machine Tool Monitoring: Used to monitor vibration and positioning in high-speed CNC or grinding equipment for precision assurance.

Advantages

-

Non-Contact Precision Measurement: Avoids mechanical wear while delivering high-resolution measurements, ideal for dynamic machinery.

-

Wide Temperature Tolerance: Operates reliably in extreme conditions, including high-temperature zones near turbines or engines.

-

High Linearity and Sensitivity: Maintains accuracy across the full range of motion, ensuring dependable data for control systems.

-

IP68 Protection: The sensor is dustproof and submersible, suitable for hazardous and outdoor industrial environments.

-

Customizable Cable Lengths: Factory-configurable cable lengths offer installation flexibility based on machinery layout.

-

Robust Industrial Design: Built from corrosion-resistant stainless steel, capable of withstanding vibrations and harsh chemical atmospheres.

-

Fast Frequency Response: Ensures accurate tracking of rapid movements, suitable for high-speed shaft vibration diagnostics.

-

Standardized Output: Compatible with industry-standard monitoring systems, making integration seamless.

-

Enhanced Machinery Safety: Provides critical input for shutdown and alarm systems, minimizing mechanical failures and costly repairs.

-

Proven Performance: Trusted by leading OEMs and industries worldwide for reliability in rotating equipment protection.

Frequently Asked Questions (FAQ)

-

Q: What is the sensing range of the PR6424/014-040 sensor?

A: It has a 16 mm linear measurement range, optimized for shaft vibration and displacement monitoring. -

Q: Is this sensor suitable for high-temperature environments?

A: Yes, the probe operates reliably up to +180°C, and the CON021 converter supports up to +85°C. -

Q: What is the role of the CON021 in this combination?

A: The CON021 converter conditions the signal from the probe and outputs a standardized analog voltage signal for monitoring systems. -

Q: What types of targets can the sensor detect?

A: It is designed for conductive targets, such as ferromagnetic metals like steel or iron. -

Q: Can the cable length between the sensor and converter be customized?

A: Yes, custom cable lengths can be specified when ordering, with standard lengths usually 5m, 7m, or 9m. -

Q: Is this sensor compatible with third-party monitoring systems?

A: Yes, the output signal is standardized (0–10 V or ±5 V) and can be used with most vibration monitoring and condition monitoring systems. -

Q: What environmental protection does the sensor offer?

A: The sensor is IP68-rated, making it suitable for wet, dusty, or pressurized environments. -

Q: How is the sensor mounted on machinery?

A: It features an M14 x 1.5 mounting thread, allowing threaded or clamped installation. -

Q: What is the typical frequency range the sensor can detect?

A: The system responds to signals from DC up to 10 kHz, depending on the converter settings. -

Q: What industries most commonly use the PR6424/014-040+CON021 sensor?

A: It is commonly used in power generation, oil & gas, chemical processing, and manufacturing industries.

Related Models from the Same Series (Epro PR6424 + CON021)

| Model | Description | Measurement Range | Application Focus |

|---|---|---|---|

| PR6424/012-010+CON021 | 16 mm eddy current sensor | 16 mm | General-purpose machinery |

| PR6424/012-030+CON021 | Extended-range version | 30 mm | Large shaft or clearance gaps |

| PR6424/014-010+CON021 | High-temperature version | 10 mm | Steam turbines, compressors |

| PR6424/002-030+CON021 | Narrow probe body for tight spaces | 30 mm | Small machines or enclosed areas |

| PR6424/003-010+CON021 | Shielded sensor version | 10 mm | High-EMI industrial environments |

| PR6424/005-010+CON021 | Probe with angled connector for confined mounting | 10 mm | Limited installation clearance |

Popular Models from Epro (Same Brand, Various Applications)

| Model | Description | Measurement Type | Key Use Case |

|---|---|---|---|

| MMS6120 | Vibration Monitoring System | Vibration | Continuous monitoring of machinery |

| PR6423/002-000 | Eddy Current Probe | Displacement | Axial and radial shaft monitoring |

| MMS6822 | Dual Channel Protection System | Vibration + Speed | Turbine safety systems |

| PR6424/001-010 | Standard eddy current sensor | Displacement | Standard turbine monitoring |

| CON021 | Signal converter for PR6424 series | Signal Conditioning | Used with all PR6424 sensors |

| MMS6312 | Transmitter Module for Vibration/Position Monitoring | Vibration/Position | Compact protection application |

Excellent PLC

Excellent PLC