| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

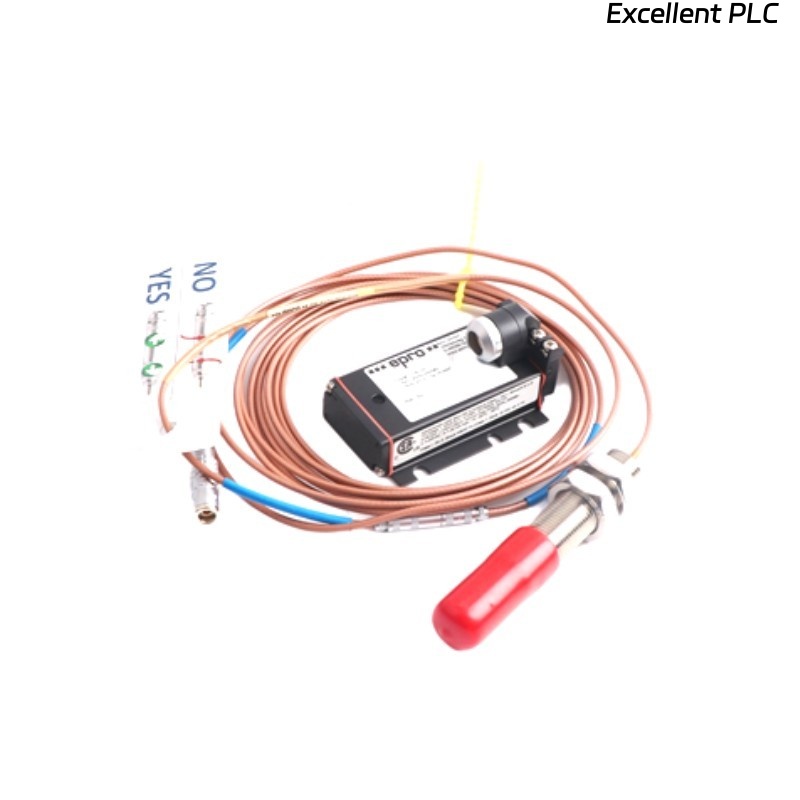

The Epro PR6424/107-000 16mm Eddy Current Sensor is a high-precision sensor designed for non-contact measurement of displacement, vibration, and position. Featuring a compact 16mm probe, this eddy current sensor is ideal for applications that require precise measurements in harsh environments. Epro’s eddy current sensors utilize advanced technology to provide real-time, high-speed feedback for industrial applications, offering both accuracy and durability.

The PR6424/107-000 sensor works based on the principle of eddy current measurement, where the sensor emits electromagnetic fields, which interact with the target material. This interaction induces eddy currents, which are then measured by the sensor to determine the distance or position of the target. This method ensures high accuracy and reliability, particularly for measuring metal surfaces.

Thanks to its robust construction and high sensitivity, the Epro PR6424/107-000 is used in various industries, including automotive, manufacturing, and aerospace, where precise measurement of dynamic conditions is critical. Its small 16mm diameter makes it ideal for confined spaces and tight integration requirements.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | PR6424/107-000 |

| Measurement Principle | Eddy Current |

| Probe Diameter | 16 mm |

| Measuring Range | Up to 10 mm |

| Output Type | Analog (Voltage, Current) |

| Output Range | 0-10 V, 4-20 mA |

| Response Time | <1 ms |

| Operating Temperature | -20°C to 85°C |

| Operating Voltage | 15 to 30 VDC |

| Dimensions (Head) | Ø16 mm |

| Weight | 0.2 kg |

Product Applications

The Epro PR6424/107-000 16mm Eddy Current Sensor is widely used in various industries where precise, non-contact measurement of displacement or position is required. Key applications include:

-

Automotive Industry: The sensor is used for monitoring the displacement and vibration of components in engines, transmissions, and other mechanical systems to ensure optimal performance and reliability.

-

Aerospace: In aerospace applications, the sensor provides precise measurement for components like turbine blades, ensuring the accurate functioning of high-precision machinery.

-

Industrial Automation: The sensor is ideal for positioning systems, quality control processes, and other automated machinery, where accurate feedback of mechanical parts is needed.

-

Vibration Monitoring: The PR6424/107-000 is perfect for vibration monitoring in rotating equipment like motors, generators, and pumps to detect misalignment or imbalance in systems.

-

Material Testing: Used in the non-destructive testing of materials, particularly to measure changes in thickness, displacement, or wear of metal surfaces.

-

Mining and Oil & Gas: The sensor helps in monitoring the position and wear of critical equipment, reducing the risk of malfunction due to wear and tear.

Advantages of the Product

The Epro PR6424/107-000 16mm Eddy Current Sensor offers numerous advantages that make it a preferred choice for industrial applications:

-

Non-Contact Measurement: By using the eddy current principle, this sensor can measure displacement, vibration, and position without coming into contact with the target, ensuring no wear on the sensor and maintaining the integrity of the measured components.

-

High Precision: With a high-frequency response and excellent resolution, the sensor delivers precise measurements even in challenging conditions, ensuring accurate and reliable results.

-

Compact Size: The 16mm diameter of the probe allows for easy integration into tight spaces or confined areas where larger sensors might not fit, making it ideal for industrial machines and equipment with limited space.

-

Wide Temperature Range: The sensor operates reliably in temperatures ranging from -20°C to 85°C, allowing for use in a variety of environments, from extremely cold to high-temperature applications.

-

Fast Response Time: The PR6424/107-000 has a very fast response time of less than 1 millisecond, making it suitable for dynamic and high-speed applications, such as machinery with rapid movements.

-

Durability and Reliability: Built to withstand harsh industrial environments, the sensor is resistant to vibrations, shock, and external electromagnetic interference, ensuring long-term performance.

-

Multiple Output Options: The sensor offers flexible output options (0-10V, 4-20mA), making it adaptable to various control systems and automation equipment.

-

Low Power Consumption: The sensor operates on a low power range (15 to 30 VDC), which helps minimize energy usage and is suitable for integration into energy-efficient systems.

FAQ

-

How does the Epro PR6424/107-000 work?

-

The PR6424/107-000 uses the eddy current principle, where electromagnetic fields interact with a metallic target, inducing eddy currents. These currents are then measured by the sensor to determine the target’s displacement or position.

-

-

What is the maximum measuring range of the sensor?

-

The sensor can measure up to 10 mm of displacement, providing highly accurate readings within this range.

-

-

What types of output does the sensor provide?

-

The PR6424/107-000 offers both voltage (0-10V) and current (4-20mA) output options, allowing compatibility with various control systems.

-

-

What is the response time of the Epro PR6424/107-000?

-

The sensor has a response time of less than 1 millisecond, making it suitable for high-speed applications where rapid measurement feedback is necessary.

-

-

What is the operating temperature range of the sensor?

-

The sensor can operate within a temperature range of -20°C to 85°C, making it suitable for use in a wide variety of industrial environments.

-

-

Can the Epro PR6424/107-000 be used in non-metallic applications?

-

No, the sensor is designed specifically for measuring metallic targets, as it operates on the eddy current principle, which relies on the conductivity of metal.

-

-

How does the sensor ensure accurate measurements in dynamic conditions?

-

The PR6424/107-000 offers high-resolution measurements with a fast response time, ensuring that even rapid changes in displacement or vibration are accurately captured in real-time.

-

-

What type of mounting is required for the sensor?

-

The Epro PR6424/107-000 is designed for simple integration into systems, but specific mounting options depend on the application and equipment. It typically mounts through threaded holes or brackets.

-

-

What is the significance of the 16mm probe diameter?

-

The compact 16mm probe allows the sensor to be used in tight spaces, where traditional larger sensors might not fit, offering flexibility in various applications.

-

-

Is the Epro PR6424/107-000 suitable for vibration monitoring?

-

Yes, the PR6424/107-000 is ideal for vibration monitoring, especially for rotating equipment like motors and pumps, helping to detect imbalances and misalignments in real-time.

-

Recommended Models

| Model Number | Description |

|---|---|

| PR6424/106-000 | 12mm Eddy Current Sensor for Precise Measurement |

| PR6424/108-000 | High-Sensitivity Eddy Current Sensor for Dynamic Monitoring |

| PR6424/109-000 | 8mm Compact Eddy Current Sensor for Tight Integration |

| PR6424/110-000 | 20mm Eddy Current Sensor for High-Precision Measurement |

| PR6424/111-000 | Dual-Channel Eddy Current Sensor for Multi-Target Applications |

| PR6424/112-000 | Long-Range Eddy Current Sensor for Large Displacement Monitoring |

Popular Models from Epro

| Model Number | Description |

|---|---|

| PR6524/104-000 | Compact Displacement Sensor for Precision Control |

| PR6404/105-000 | Industrial Vibration Monitoring Sensor |

| PR6303/106-000 | High-Speed Position Sensor for Motors |

| PR6203/107-000 | Non-Contact Measuring Sensor for Aerospace Applications |

| PR6003/108-000 | Multi-Channel Vibration Sensor for Industrial Automation |

| PR5503/109-000 | Precision Thickness Measurement Sensor |

Excellent PLC

Excellent PLC