| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

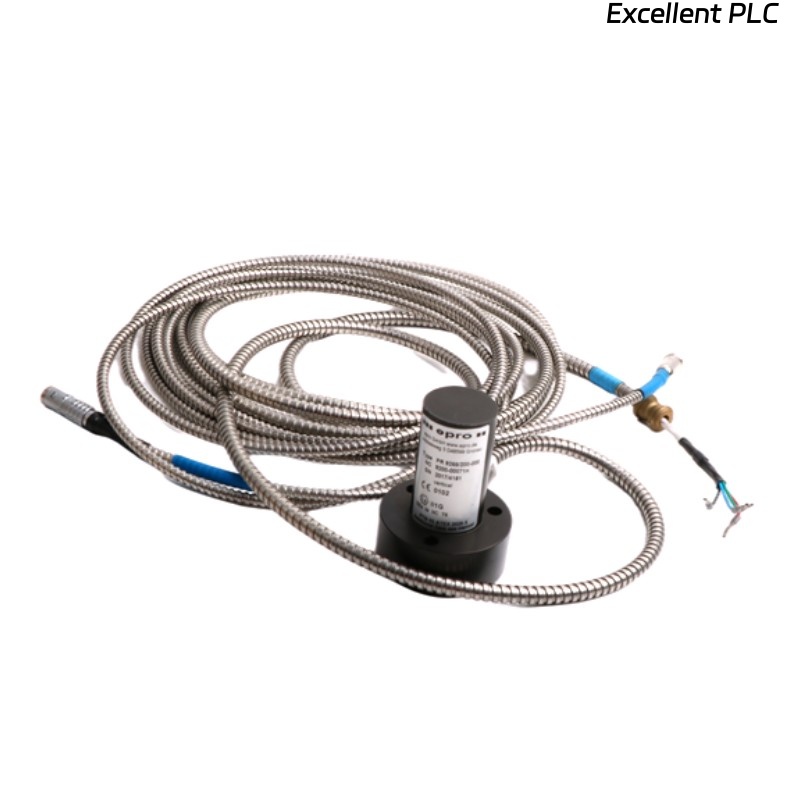

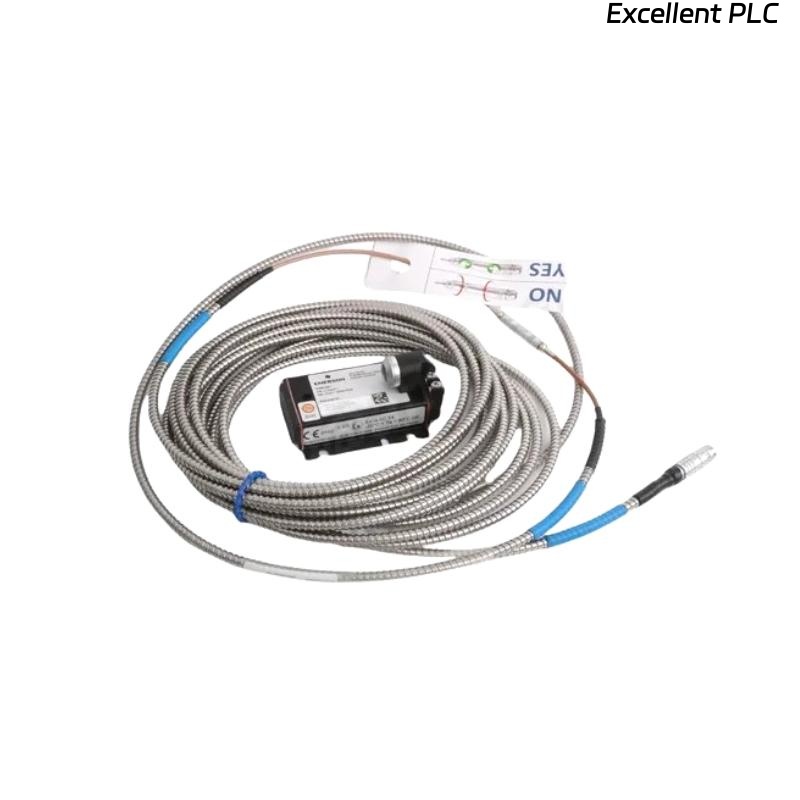

The Epro PR6425/005-010 is a 16mm Eddy Current Sensor designed for precision measurement of displacement, vibration, and position in industrial machinery. This sensor is part of Epro’s PR6425 series, providing accurate non-contact measurement with high linearity and stability.

The sensor operates based on the eddy current principle, where variations in proximity between the sensor tip and a conductive target cause changes in electrical impedance. These changes are converted into proportional electrical signals suitable for control systems, diagnostics, and condition monitoring.

The PR6425/005-010 is optimized for industrial environments with vibration, electromagnetic interference, and temperature fluctuations, making it suitable for power generation, turbine monitoring, heavy machinery, and industrial automation. Its robust stainless steel construction ensures durability, while the 16mm diameter provides a balance between compact size and high measurement accuracy.

Technical Specifications

| Parameter | Specification |

|---|---|

| Sensor Type | Eddy Current |

| Sensor Head Diameter | 16 mm |

| Weight | 0.5 kg |

| Measurement Range | 0–5 mm standard, customizable |

| Linearity | ±1% full scale |

| Frequency Response | DC to 20 kHz |

| Output Signal | Analog 0–10 V or 4–20 mA |

| Operating Temperature | -40°C to +125°C |

| Supply Voltage | 18–30 V DC |

| Protection | IP65 (sensor head) |

| Material | Stainless steel body with non-magnetic tip |

| Mounting Options | Threaded or flange mount |

| Environmental Resistance | Vibration up to 20 g, EMI resistant |

Applications

The PR6425/005-010 sensor is suitable for:

-

Monitoring shaft displacement and position in turbines, generators, and motors

-

Detecting vibration amplitudes for predictive maintenance

-

Identifying shaft misalignment or eccentricity in high-speed machinery

-

Integration into industrial automation systems requiring precise displacement feedback

-

Condition monitoring in aerospace, power plants, and heavy industry

-

Environments requiring non-contact measurement to reduce wear and maintenance

Its 16mm diameter provides a practical size for installation in industrial equipment while maintaining high measurement accuracy.

Advantages

-

High Precision – ±1% full scale linearity ensures reliable measurements.

-

Moderate Size – 16mm head provides compactness without sacrificing performance.

-

Non-Contact Measurement – Reduces mechanical wear and maintenance requirements.

-

Robust Construction – Stainless steel body resists corrosion and mechanical stress.

-

Fast Response – Suitable for detecting rapid changes in displacement or vibration.

-

EMI and Vibration Resistant – Ensures reliable data even in electrically noisy environments.

-

Versatile Integration – Compatible with a wide range of industrial monitoring and control systems.

FAQ

-

What is the maximum measurement frequency for this sensor?

It can measure signals up to 20 kHz, suitable for high-speed rotating machinery. -

What type of output signal does it provide?

The sensor provides 0–10 V analog or 4–20 mA output. -

Can it operate in extreme temperatures?

Yes, it functions reliably between -40°C and +125°C. -

Is it resistant to electromagnetic interference?

Yes, the sensor is EMI shielded for stable performance in noisy environments. -

What is the linearity specification?

Linearity is ±1% full scale, ensuring accurate and repeatable readings. -

Can it detect small shaft vibrations?

Yes, it can detect sub-micron vibration amplitudes, suitable for condition monitoring. -

How is it mounted?

Supports threaded or flange mount for flexible installation. -

What protection does the sensor offer against dust and water?

The sensor head is rated IP65, protecting it from dust and low-pressure water jets. -

Is it suitable for high-speed rotating machinery?

Yes, it is designed for turbines, compressors, and motors operating at high speeds. -

What materials are used in the construction?

Stainless steel body with a non-magnetic tip ensures durability and corrosion resistance.

Related or Series Models

| Model | Sensor Head Diameter | Measurement Range | Output | Weight |

|---|---|---|---|---|

| PR6425/004-010 | 16 mm | 0–4 mm | 0–10 V / 4–20 mA | 0.48 kg |

| PR6425/006-010 | 16 mm | 0–6 mm | 0–10 V / 4–20 mA | 0.52 kg |

| PR6425/008-010 | 16 mm | 0–8 mm | 0–10 V / 4–20 mA | 0.53 kg |

| PR6425/010-010 | 16 mm | 0–10 mm | 0–10 V / 4–20 mA | 0.55 kg |

| PR6425/005-020 | 16 mm | 0–5 mm | 0–5 V / 0–20 mA | 0.50 kg |

| PR6425/007-010 | 16 mm | 0–7 mm | Differential output | 0.51 kg |

Popular Epro Models

| Model | Sensor Head Diameter | Measurement Range | Output | Weight |

|---|---|---|---|---|

| PR6424/014-040 | 14 mm | 0–4 mm | 0–10 V | 0.8 kg |

| PR6424/022-100 | 22 mm | 0–10 mm | 0–10 V / 4–20 mA | 1.2 kg |

| PR6426/010-100 | 32 mm | 0–10 mm | 0–10 V | 1.3 kg |

| PR6426/020-120 | 32 mm | 0–15 mm | 0–10 V / 4–20 mA | 1.5 kg |

| PR6430/010-110 | 30 mm | 0–10 mm | 0–10 V | 1.4 kg |

| PR6430/015-120 | 30 mm | 0–15 mm | 0–10 V / 4–20 mA | 1.6 kg |

Excellent PLC

Excellent PLC