| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

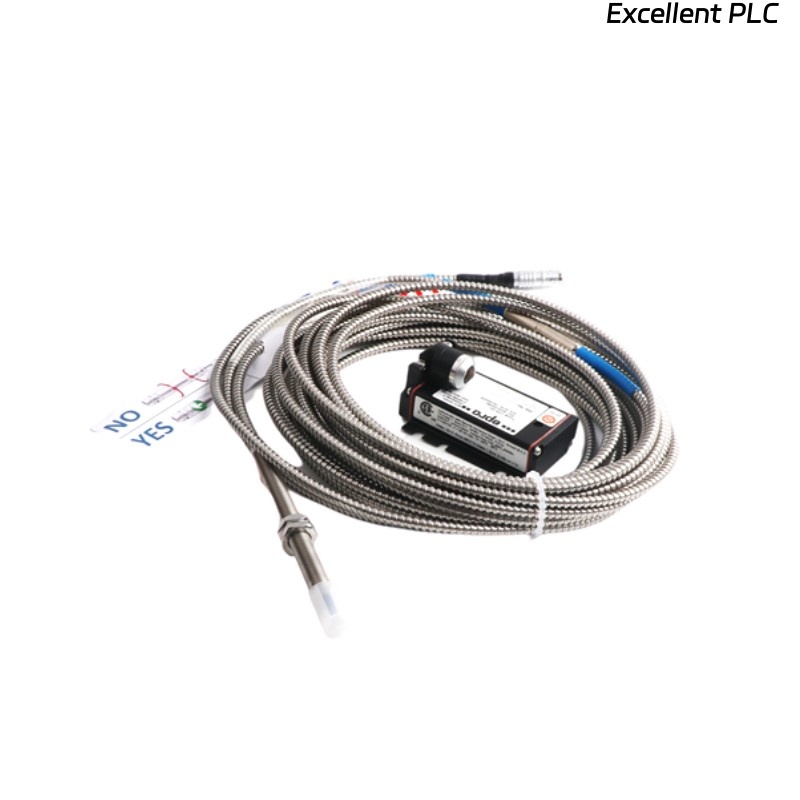

The EPRO PR6425/010-130 Eddy Current Sensor is a high-precision, non-contact displacement and vibration measurement sensor designed for industrial machinery monitoring applications. This model is part of EPRO’s advanced PR6425 series, which is well-known for its exceptional reliability, durability, and stability in harsh environments. Utilizing eddy current measurement technology, it provides accurate monitoring of shaft vibration, displacement, and position in rotating machines such as turbines, compressors, generators, and motors.

The PR6425/010-130 is engineered to work seamlessly with EPRO’s MMS6000 and MMS3000 condition monitoring systems, ensuring precise data transmission and compatibility. Its robust stainless-steel housing and compact structure make it suitable for long-term deployment in challenging industrial environments involving high temperatures, humidity, and electromagnetic interference.

Technical Specifications

| Parameter | Description |

|---|---|

| Product Model | PR6425/010-130 |

| Type | Eddy Current Displacement Sensor |

| Sensing Principle | Eddy Current (Non-contact) |

| Sensor Head Diameter | 16 mm |

| Measurement Range | Typically ±2 mm to ±4 mm (depending on system configuration) |

| Sensitivity | 4 mV/µm (typical) |

| Linearity | ≤ ±1% of full scale |

| Frequency Range | DC to 10 kHz |

| Operating Temperature | -35°C to +180°C |

| Storage Temperature | -40°C to +200°C |

| Output Signal | Voltage (proportional to displacement) |

| Power Supply | Via connected proximity transducer driver |

| Housing Material | Stainless Steel |

| Connector Type | EPRO standard coaxial connector |

| Insulation Resistance | ≥ 100 MΩ |

| Mounting | Threaded mounting for secure installation |

| Sensor Head Diameter | 16 mm |

| Weight | 0.5 kg |

| Protection Class | IP67 |

| Compatibility | EPRO PR6423, PR6424, MMS6000, MMS3000 Systems |

Product Applications

The EPRO PR6425/010-130 is specifically designed for industrial machinery condition monitoring and protection. Its applications include:

-

Turbomachinery Monitoring: Measurement of shaft vibration and axial displacement in gas turbines, steam turbines, and turbo compressors.

-

Generator and Motor Monitoring: Continuous monitoring of bearing and rotor movements for predictive maintenance.

-

Compressor Protection Systems: Preventing mechanical failures due to excessive shaft vibration or misalignment.

-

Pumps and Fans: Detecting imbalance and misalignment in high-speed rotating equipment.

-

Research and Test Facilities: Used in laboratory testing for vibration analysis and calibration setups.

Its reliability in extreme industrial environments makes it a preferred choice for power plants, petrochemical plants, and offshore oil and gas installations, where continuous operation and accurate data are critical.

Product Advantages

The EPRO PR6425/010-130 offers several key advantages that make it stand out in precision measurement and machinery protection systems:

-

High Measurement Accuracy: Provides stable and repeatable measurements of vibration and displacement.

-

Non-contact Design: Eliminates mechanical wear, ensuring long-term stability and minimal maintenance.

-

Robust Construction: Stainless-steel housing ensures durability in high-vibration and high-temperature environments.

-

Excellent Temperature Stability: Maintains consistent performance across a wide temperature range.

-

EMI Resistance: Immune to electromagnetic interference, ensuring signal integrity in electrically noisy environments.

-

Seamless Compatibility: Fully compatible with EPRO monitoring systems and transducer drivers.

-

Easy Installation and Maintenance: Threaded design simplifies mounting and replacement.

-

High Reliability: Proven performance in demanding industrial applications.

FAQ

-

What is the operating principle of the PR6425/010-130 sensor?

The sensor operates based on the eddy current principle, where a high-frequency electromagnetic field interacts with a conductive target to measure changes in displacement or vibration. -

Which monitoring systems are compatible with the PR6425/010-130?

It is compatible with EPRO’s MMS6000 and MMS3000 systems, as well as transducer drivers like CON021 and CON041. -

What is the typical output signal type?

The sensor provides a voltage output proportional to the measured displacement, typically in the range of several millivolts per micron. -

Can this sensor operate in high-temperature environments?

Yes, the PR6425/010-130 is designed for continuous operation at temperatures up to +180°C, with stability ensured through robust thermal insulation. -

How does the PR6425/010-130 ensure signal stability?

The sensor uses advanced electromagnetic shielding and high-quality internal components to minimize noise and maintain signal precision. -

Is calibration required for this sensor?

The sensor is factory-calibrated, but field calibration can be performed for precise system integration using standard EPRO calibration procedures. -

What is the frequency response range of this sensor?

It supports a wide frequency range from DC up to 10 kHz, allowing for accurate monitoring of both static and dynamic movements. -

Can the PR6425/010-130 detect shaft runout and rotor position?

Yes, it is specifically designed to detect shaft vibration, runout, and relative displacement between rotor and bearing housing. -

What type of mounting is recommended for optimal performance?

Threaded mounting on a rigid bracket is recommended to ensure stable positioning and accurate signal readings. -

How does it perform under high vibration conditions?

The sensor’s robust mechanical structure and sealed housing enable it to function reliably even in environments with high levels of mechanical vibration.

Recommended Related Models (Same Series or Similar Types)

| Model | Description | Sensor Diameter | Weight |

|---|---|---|---|

| PR6425/010-120 | Eddy Current Sensor, high sensitivity | 16 mm | 0.5 kg |

| PR6425/010-140 | Extended range vibration sensor | 16 mm | 0.5 kg |

| PR6425/011-130 | Improved thermal resistance model | 16 mm | 0.52 kg |

| PR6425/012-130 | For high-frequency vibration detection | 16 mm | 0.5 kg |

| PR6425/015-120 | Compact model for tight installation | 12 mm | 0.4 kg |

| PR6424/000-030 | Standard eddy current sensor, general-purpose | 8 mm | 0.35 kg |

Popular Models from the Same Brand (EPRO)

| Model | Description | Measurement Type | Weight |

|---|---|---|---|

| MMS6000 | Machinery Monitoring System | Multi-channel vibration and displacement monitoring | 5.2 kg |

| MMS3120/022-100 | Vibration Measurement Module | Condition monitoring | 0.8 kg |

| MMS3125/022-020 | Proximity Signal Conditioner | Signal conversion | 0.9 kg |

| PR6423/10R-010 | Eddy Current Sensor | Shaft vibration detection | 0.45 kg |

| CON021 | Proximity Transducer Driver | Sensor signal processing | 0.35 kg |

| CON041 | Dual-channel Transducer Driver | Dynamic monitoring system | 0.36 kg |

Excellent PLC

Excellent PLC