| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

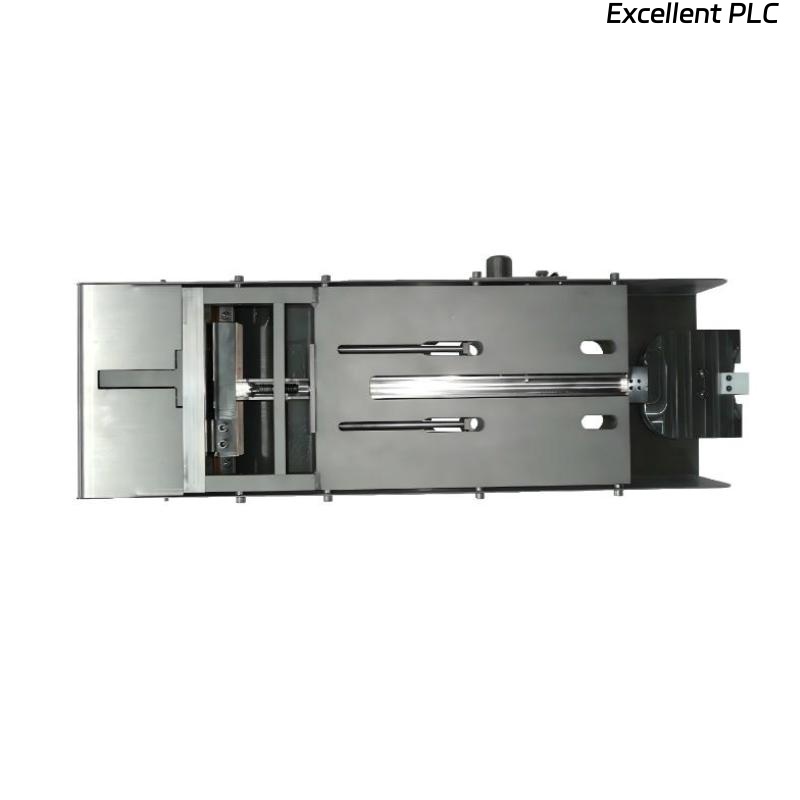

The EPRO PR6426/000-001 is a high-precision 32mm eddy current sensor designed for displacement, position, and vibration monitoring in rotating machinery and industrial equipment. It employs the eddy current principle, allowing non-contact measurement of conductive targets with high repeatability and minimal mechanical wear.

The sensor’s stainless-steel housing ensures robust performance under harsh operating conditions, including high vibration, temperature fluctuations, and electromagnetic interference. The PR6426/000-001 is widely used in conjunction with EPRO transducer drivers, such as the CON021, enabling seamless integration into machinery monitoring systems.

This sensor is ideal for predictive maintenance applications, allowing early detection of rotor imbalance, misalignment, or bearing anomalies, thereby reducing unplanned downtime and improving operational safety.

Technical Specifications

| Parameter | Description |

|---|---|

| Product Model | PR6426/000-001 |

| Type | Eddy Current Sensor |

| Sensor Head Diameter | 32 mm |

| Measurement Principle | Eddy Current (Non-contact) |

| Measurement Range | ±2 mm to ±10 mm (depending on setup) |

| Sensitivity | 4 mV/µm (typical) |

| Frequency Response | DC to 10 kHz |

| Linearity | ≤ ±1% of full scale |

| Operating Temperature | -35°C to +180°C |

| Storage Temperature | -40°C to +200°C |

| Output Signal | Voltage proportional to displacement |

| Supply Voltage | Via compatible transducer driver |

| Housing Material | Stainless Steel |

| Mounting Type | Threaded mounting |

| Insulation Resistance | ≥ 100 MΩ |

| Protection Class | IP67 |

| Connection Type | Standard EPRO coaxial connector |

| Compatible Systems | MMS6000, MMS3000, PR6426 series |

| Weight | 0.8 kg |

Product Applications

The PR6426/000-001 is used in industrial machinery monitoring where precision and reliability are crucial. Typical applications include:

-

Turbines: Monitoring rotor displacement and vibration.

-

Compressors and Pumps: Detecting imbalance, misalignment, and bearing anomalies.

-

Motors and Generators: Real-time monitoring of shaft motion and performance.

-

Fans and Blowers: Detecting excessive vibration and operational irregularities.

-

Power Plants: Integrating into predictive maintenance systems for continuous performance assurance.

-

Petrochemical Industry: Monitoring high-speed shafts in extreme environmental conditions.

Product Advantages

The EPRO PR6426/000-001 sensor provides several advantages:

-

High Accuracy: Precise measurement of displacement and vibration.

-

Non-contact Operation: Reduces mechanical wear and maintenance requirements.

-

Robust Construction: Stainless steel housing withstands harsh environments.

-

EMI Resistance: Shielded design ensures signal stability in electrically noisy conditions.

-

Wide Frequency Response: Suitable for both static and dynamic measurements.

-

Seamless Integration: Compatible with EPRO transducer drivers and monitoring systems.

-

Stable Output: Maintains integrity under vibration and temperature changes.

-

Flexible Mounting: Threaded design allows secure installation.

-

Low Maintenance: Non-contact design reduces servicing frequency.

-

Proven Reliability: Widely used in industrial predictive maintenance programs.

FAQ

-

What principle does this sensor operate on?

It uses the eddy current principle, detecting changes in impedance caused by nearby conductive materials. -

Which systems can this sensor integrate with?

Compatible with MMS6000, MMS3000, and EPRO transducer drivers such as CON021. -

What type of output signal is provided?

A voltage proportional to the measured displacement. -

How linear is the measurement across the range?

Linearity is within ±1% of full-scale across the specified measurement range. -

Can it operate in high-vibration conditions?

Yes, its robust design and shielding ensure stable performance under vibration. -

Does the sensor require an external power source?

Power is supplied via the compatible transducer driver. -

What is the frequency response range?

DC to 10 kHz, suitable for both slow displacement and high-speed vibration measurements. -

What is the recommended mounting method?

Threaded mounting provides mechanical stability and proper alignment with the target. -

How does the sensor handle electromagnetic interference?

Internal EMI shielding ensures minimal signal disturbance in noisy environments. -

Is calibration needed after installation?

Factory calibration ensures accuracy, though system-level fine-tuning can be applied for specific machinery conditions.

Recommended Related Models (Same Series or Similar Types)

| Model | Description | Sensor Diameter | Weight |

|---|---|---|---|

| PR6426/010-100 | Standard 32mm eddy current sensor | 32 mm | 0.8 kg |

| PR6426/010-110 | High-sensitivity version | 32 mm | 0.8 kg |

| PR6426/010-120 | Medium-range displacement sensor | 32 mm | 0.82 kg |

| PR6426/011-130 | High-frequency response model | 32 mm | 0.83 kg |

| PR6425/010-140 | 16 mm compact probe | 16 mm | 0.5 kg |

| PR6424/000-030 | 8 mm general-purpose probe | 8 mm | 0.35 kg |

Popular Models from the Same Brand (EPRO)

| Model | Description | Measurement Type | Weight |

|---|---|---|---|

| MMS6000 | Multi-channel machinery monitoring system | Vibration and displacement | 5.2 kg |

| MMS3120/022-100 | Vibration measurement module | Real-time condition monitoring | 0.8 kg |

| MMS3125/022-020 | Signal conditioner module | Converts sensor output to voltage | 0.9 kg |

| PR6425/010-130 | 16 mm eddy current sensor | Shaft displacement monitoring | 0.5 kg |

| CON011 | Single-channel transducer driver | Signal conversion and amplification | 0.35 kg |

| CON021 | Dual-channel transducer driver | Advanced monitoring interface | 0.36 kg |

Excellent PLC

Excellent PLC