| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

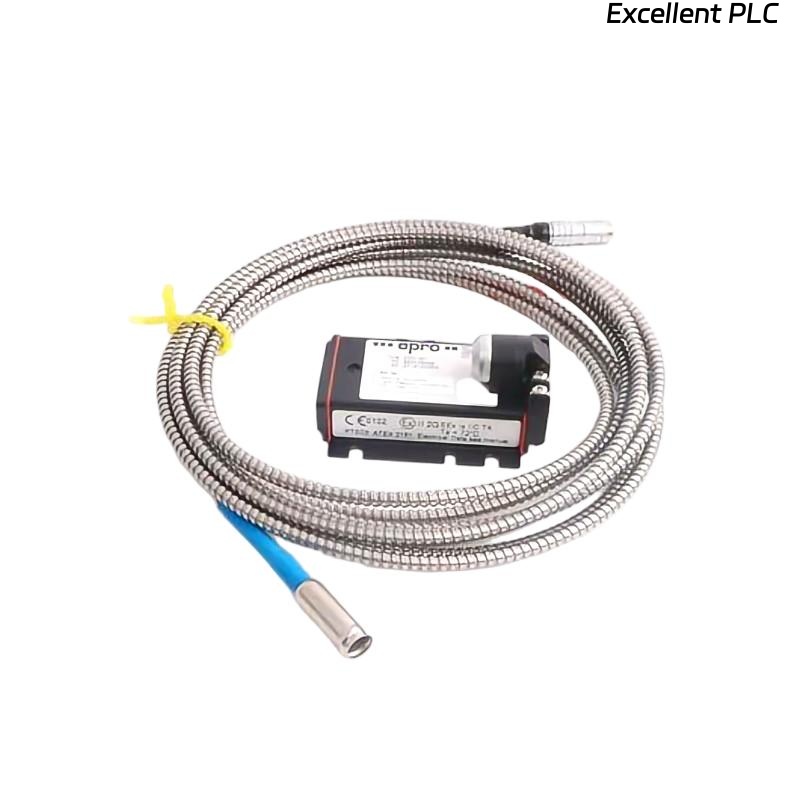

The Epro PR6426/000-111 32mm Eddy Current Sensor is a precision-engineered, non-contact measurement device designed for critical industrial machinery monitoring. It provides accurate detection of shaft vibration, axial displacement, and rotational movement, ensuring the reliable performance of turbines, compressors, generators, and other rotating equipment.

The sensor operates on the eddy current principle, where a high-frequency electromagnetic field is generated at the sensor tip. When a conductive target enters this field, eddy currents are induced, altering the field and generating a voltage proportional to the distance between the target and the sensor. This non-contact approach eliminates mechanical wear, enhances long-term reliability, and maintains measurement stability even in harsh industrial environments.

With a 32mm sensor head diameter, the PR6426/000-111 is suitable for monitoring larger shafts or broader target surfaces. It integrates with Epro signal conditioning converters, providing a linear output compatible with industrial monitoring and control systems, making it ideal for predictive maintenance programs and real-time machinery protection.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | PR6426/000-111 |

| Sensor Type | Eddy Current Proximity Probe |

| Measuring Principle | Non-contact electromagnetic induction (eddy current) |

| Sensor Head Diameter | 32 mm |

| Measuring Range | 0.25 mm – 4.0 mm (depending on target material) |

| Linearity | ≤ ±1% of full scale |

| Frequency Response | DC to 10 kHz (-3 dB) |

| Sensitivity | 4–8 mV/µm (depending on converter) |

| Target Material | Ferromagnetic and conductive materials (e.g., steel, nickel alloys) |

| Operating Temperature | -35 °C to +180 °C |

| Storage Temperature | -40 °C to +200 °C |

| Housing Material | Stainless steel (AISI 316L) |

| Protection Class | IP67 |

| Mounting Thread | M32 × 1.5 |

| Output Signal | Compatible with Epro signal conditioning converters |

| Weight | 0.8 kg |

| Compliance | CE, RoHS, optional ATEX Zone 2 |

Product Applications

The PR6426/000-111 is widely used in industrial machinery monitoring to provide real-time data for predictive maintenance and operational safety. Typical applications include:

-

Steam and gas turbines – Monitoring axial displacement and shaft vibration for early fault detection.

-

Compressors and pumps – Assessing rotor alignment and bearing performance.

-

Generators and motors – Detecting abnormal shaft movement or vibration.

-

Gearboxes and turboexpanders – Monitoring eccentric motion and mechanical stress.

-

Industrial plants – Integration with predictive maintenance and condition monitoring systems.

Its robust construction and IP67-rated housing ensure reliable operation in environments with high vibration, dust, oil, or extreme temperatures.

Product Advantages

-

Non-Contact Measurement – Reduces mechanical wear and ensures long-term reliability.

-

High Accuracy and Sensitivity – Delivers precise displacement and vibration readings.

-

Wide Frequency Response – Captures both low- and high-frequency vibration events.

-

Industrial-Grade Housing – Stainless steel casing with IP67 protection provides durability in harsh environments.

-

Large Sensor Head Diameter – 32 mm ensures accurate readings on larger shafts or broad surfaces.

-

Easy System Integration – Compatible with Epro signal conditioning converters for linear output.

-

Temperature Compensation – Maintains stable measurements over a wide temperature range.

-

Proven Industrial Reliability – Extensively used in turbines, compressors, and generators worldwide.

FAQ

-

What is the operating principle of the PR6426/000-111?

It uses the eddy current principle to detect changes in an electromagnetic field caused by conductive targets. -

Which target materials are suitable for this sensor?

Ferromagnetic and conductive materials such as steel and nickel alloys. -

Can this sensor measure both radial and axial displacement?

Yes, depending on installation orientation and monitoring system configuration. -

What is the sensor’s frequency response range?

DC to 10 kHz (-3 dB), suitable for capturing low and high-frequency shaft vibrations. -

How is the sensor integrated into monitoring systems?

Through Epro signal conditioning converters, providing a linear voltage or current output. -

Does temperature affect measurement accuracy?

Temperature compensation maintains reliable readings across -35 °C to +180 °C. -

Is the PR6426/000-111 suitable for high-vibration environments?

Yes, its industrial-grade design ensures stable operation under mechanical vibration and shock. -

Does the sensor require calibration in the field?

It is factory-calibrated; fine-tuning can be performed using Epro configuration tools if needed. -

Can this sensor be used in dual-channel or redundant monitoring systems?

Yes, it supports integration into dual-channel or redundant setups. -

What type of signal output does the sensor provide?

Via Epro converters, it provides a linear voltage or current output proportional to target displacement.

Related Models (Same Series)

| Model | Description | Sensor Head Diameter | Weight |

|---|---|---|---|

| PR6426/000-000 | Standard eddy current probe | 32 mm | 0.8 kg |

| PR6426/000-010 | High-temperature variant | 32 mm | 0.8 kg |

| PR6426/000-030 | Converter-compatible version | 32 mm | 0.92 kg |

| PR6426/000-031 | High-precision probe | 32 mm | 0.8 kg |

| PR6426/000-041 | Industrial grade sensor | 32 mm | 0.8 kg |

| PR6426/000-100 | High-performance probe | 32 mm | 0.8 kg |

Popular Models from the Same Brand (Epro)

| Model | Description | Measurement Type | Weight |

|---|---|---|---|

| PR6423/002-030 | Standard eddy current sensor | Vibration/Displacement | 0.6 kg |

| PR6424/014-040 | Proximity probe | Axial displacement | 0.7 kg |

| PR6425/010-030 | Shaft vibration sensor | Vibration | 0.8 kg |

| PR6422/010-030 | Compact displacement sensor | Bearing displacement | 0.5 kg |

| MMS3120/022-100 | Vibration monitoring module | Condition monitoring | 1.2 kg |

| MMS6822 | Dual-channel vibration monitor | Shaft and casing vibration | 1.5 kg |

Excellent PLC

Excellent PLC