| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

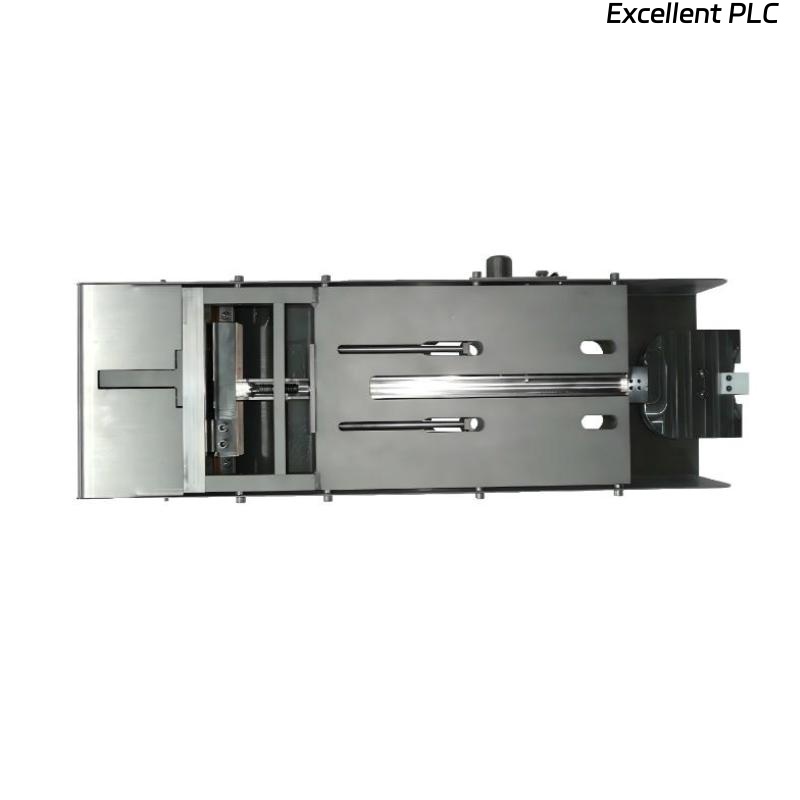

The Epro PR6426/010-040 32mm Eddy Current Sensor is a high-precision non-contact displacement and vibration sensor specifically engineered for industrial machinery monitoring. It belongs to the PR6426 series, a line of eddy current sensors developed by Epro for the measurement of shaft position, vibration, and relative movement in rotating machines. This sensor operates based on the eddy current principle, producing an analog voltage proportional to the gap between the probe tip and the conductive target.

The PR6426/010-040 is built with a robust 32 mm sensing head, ensuring excellent stability, linearity, and signal quality even under demanding operational conditions. It is particularly suited for applications in turbines, compressors, generators, and other rotating equipment where early detection of mechanical anomalies is critical.

When paired with the Epro CON021 converter, the sensor delivers highly accurate, conditioned output signals for use in machinery protection and condition monitoring systems. Designed to withstand high temperatures, heavy vibration, and electromagnetic interference, this model represents a reliable, long-term monitoring solution for critical assets in power generation, petrochemical, and process industries.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | PR6426/010-040 |

| Manufacturer | Epro |

| Sensor Type | Eddy Current Displacement and Vibration Sensor |

| Measurement Principle | Non-contact electromagnetic induction (eddy current) |

| Measurement Range | 1.0 mm to 2.5 mm (depending on setup and material) |

| Sensor Head Diameter | 32 mm |

| Weight | 0.8 kg |

| Frequency Response | 0.5 Hz to 20 kHz |

| Output Signal (via converter) | Differential analog voltage |

| Compatible Converter | CON021 |

| Power Supply (via converter) | +24 VDC nominal |

| Operating Temperature | -35°C to +180°C |

| Storage Temperature | -40°C to +200°C |

| Target Material | Ferromagnetic metals (steel, iron, nickel alloys) |

| Sensitivity | Factory-calibrated to match converter characteristics |

| Linearity Error | ≤ ±1% of full-scale output |

| Mounting Type | Threaded or flange mounting |

| Protection Class | IP65 (probe head and converter assembly) |

| Insulation Resistance | >10 MΩ at 500 VDC |

| Compliance | CE / ATEX certified for industrial applications |

Applications

The Epro PR6426/010-040 is designed for precision displacement and vibration measurement in complex rotating machinery. It provides real-time data for monitoring and protection systems, ensuring that mechanical wear or imbalance is detected before failure occurs.

Typical application areas include:

-

Steam and Gas Turbines: Measures shaft position and vibration amplitude for bearing protection and control systems.

-

Compressors and Pumps: Monitors rotor movement and imbalance to prevent catastrophic equipment failure.

-

Motors and Generators: Detects shaft eccentricity, misalignment, and vibration irregularities for predictive maintenance.

-

Machinery Protection Systems: Integrates seamlessly with Epro’s MMS monitoring systems or third-party control units.

-

Process and Petrochemical Plants: Operates reliably in high-temperature and high-vibration environments.

-

Heavy Industrial Equipment: Used for structural vibration analysis and condition monitoring in high-speed rotating machines.

Advantages

The PR6426/010-040 32mm Eddy Current Sensor combines precision engineering with proven durability, offering several advantages for continuous industrial use:

-

Non-Contact Operation: Eliminates mechanical wear and ensures accurate long-term performance.

-

High Measurement Accuracy: Provides stable readings with minimal linearity deviation across full-scale operation.

-

Wide Frequency Response: Captures both low-speed displacement and high-frequency vibration signals.

-

Temperature Resistance: Engineered to withstand continuous operation at temperatures up to +180°C.

-

Strong Signal Integrity: Shielded construction minimizes electromagnetic and radio frequency interference.

-

Easy Integration: Fully compatible with Epro’s CON021 converter and other standard monitoring interfaces.

-

Long-Term Reliability: Designed for continuous use in demanding industrial environments with minimal maintenance.

-

Industrial Durability: Built with corrosion-resistant materials suitable for oil, gas, and power applications.

FAQ

-

What type of measurement does this sensor perform?

It measures displacement and vibration of metallic targets using the non-contact eddy current method. -

What type of converter should be used with this sensor?

The sensor is designed to operate with the Epro CON021 converter, which processes the raw signal for monitoring systems. -

Can this sensor be used in high-vibration environments?

Yes, it is built for stable performance in environments with significant mechanical vibration, such as turbines and compressors. -

How does the sensor achieve non-contact measurement?

It generates an alternating magnetic field; the induced eddy currents in the target material modify the return signal proportional to the gap distance. -

Is it compatible with non-Epro monitoring systems?

Yes, the conditioned analog output from the converter can be interfaced with most third-party condition monitoring systems. -

What is the recommended target material for optimal accuracy?

The sensor is optimized for ferromagnetic materials like carbon steel, iron, and nickel-based alloys. -

How is temperature stability achieved?

The sensor’s internal electronics and probe materials are engineered for minimal drift over a wide temperature range. -

Does this sensor provide both static and dynamic signal outputs?

Yes, it simultaneously measures static shaft displacement and dynamic vibration signals. -

Can multiple sensors be used in one monitoring system?

Yes, multiple sensors can be installed and configured with corresponding converters for multi-point monitoring. -

How is electromagnetic interference minimized?

The sensor and cable assembly are shielded and use differential transmission to eliminate external noise effects.

Related and Series Models

| Model Number | Description |

|---|---|

| PR6426/000-000 | Standard 32mm eddy current probe for displacement monitoring |

| PR6426/010-000 | General-purpose probe for medium-range vibration measurement |

| PR6426/010-010 | Enhanced linearity model for precision monitoring |

| PR6426/010-020 | High-sensitivity probe for dynamic displacement detection |

| PR6426/010-060 | Extended range version for large shaft movement measurement |

| PR6426/012-000 | Explosion-proof variant suitable for hazardous industrial environments |

Popular Epro Models

| Model Number | Description |

|---|---|

| PR6423/002-030+CON021 | Standard eddy current probe with converter for turbine monitoring |

| PR6423/005-010 | Compact probe for close-range displacement measurement |

| PR6424/01CS | Precision proximity sensor for axial shaft monitoring |

| PR6424/014-040+CON021 | Advanced eddy current probe for high-performance machinery protection |

| MMS3120/022-100 | Multi-channel monitoring and protection module |

| PR6423/001-010-CN | Industrial-grade eddy current sensor with high accuracy signal output |

Excellent PLC

Excellent PLC