| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

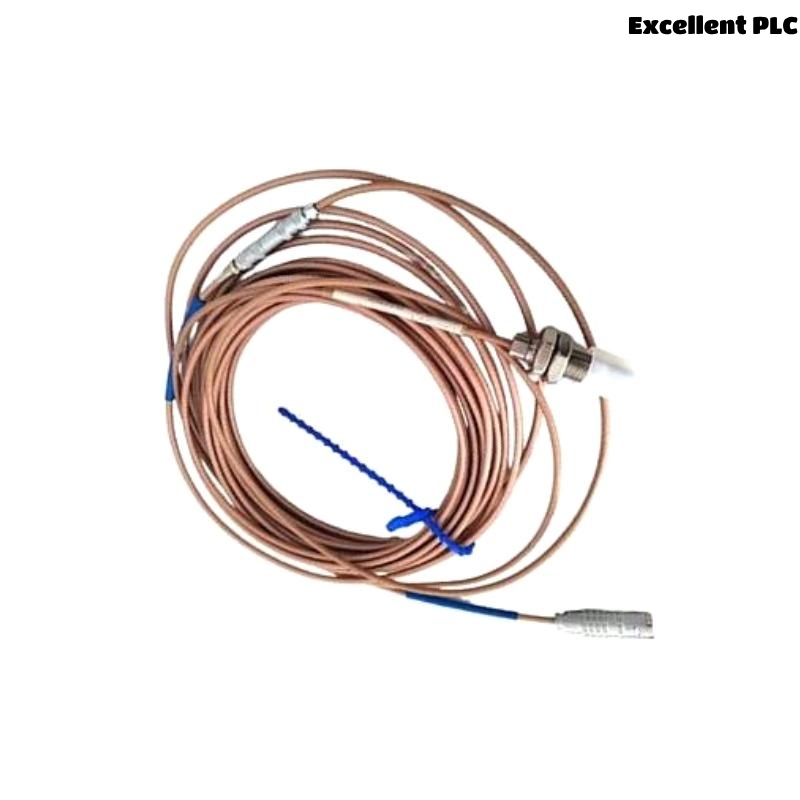

The Epro PR6426/010-140 + CON010 is a high-precision eddy current sensor system designed to monitor and measure the displacement, position, and vibration of rotating machinery. Manufactured by Epro, a reputable brand under the NVE Corporation / Brüel & Kjær Vibro, this sensor is widely used in condition monitoring systems across various industrial sectors, especially within power generation, petrochemical, and heavy machinery environments.

This particular model features a 32mm probe, allowing it to offer extended measurement ranges and robust performance in harsh environments. Paired with the CON010 connector, it ensures reliable signal transmission and installation convenience.

Product Specifications

| Parameter | Details |

|---|---|

| Model | PR6426/010-140 + CON010 |

| Sensor Head Diameter | 32 mm |

| Measurement Range | 0 to 4 mm (standard), depending on setup |

| Sensitivity | Approx. 7.87 mV/μm (typical) |

| Linearity Error | < ±1% of Full Scale |

| Frequency Response | 0 to 10 kHz (-3dB) |

| Output Signal | Voltage output (via CON010) |

| Connector Type | CON010 (removable connection) |

| Cable Length | Standard 5 m, customizable on request |

| Operating Temperature | -35°C to +180°C |

| Storage Temperature | -40°C to +200°C |

| Pressure Resistance | Up to 10 bar |

| Vibration Limit | Up to 20 g |

| Housing Material | Stainless Steel |

| Protection Class | IP68 (sensor); IP65 (connector) |

| Weight | 1.4 kg |

| Compliance | CE, ATEX Zone 1 certified (optional) |

Product Applications

-

Turbomachinery Monitoring: Ideal for detecting shaft vibration and radial/axial displacement in turbines, compressors, and generators.

-

Hydroelectric Power Plants: Monitoring the shaft movement and rotor position in water turbines.

-

Oil & Gas Industry: Suitable for pumps, compressors, and motors operating under explosive or high-temperature environments.

-

Steel and Cement Industry: Used to monitor large rotary equipment like kilns and rolling mills.

-

Process Automation: Integrated into control systems for predictive maintenance and real-time machine health analysis.

-

Condition Monitoring Systems (CMS): Compatible with Epro and Vibro-Meter monitoring systems.

Product Advantages

-

High Precision: Excellent resolution and sensitivity, suitable for demanding measurement tasks.

-

Robust Construction: Made from stainless steel, withstanding extreme environments such as high temperatures and vibrations.

-

Flexible Installation: Compatible with various cable lengths and mounting configurations.

-

Long-Term Stability: Minimal signal drift and reliable performance over extended operational periods.

-

Non-Contact Measurement: Prevents wear and tear, ensuring longer operational life and reducing maintenance costs.

-

Wide Compatibility: Fully integrable with Epro’s CMS and compatible third-party systems.

-

Certified for Hazardous Areas: Available with ATEX certification for use in potentially explosive atmospheres.

-

Waterproof Design: IP68-rated protection ensures reliable operation in submerged or wet environments.

-

Field-Proven Technology: Trusted by industries worldwide for critical machinery monitoring.

-

Modular System: Interchangeable probes, cables, and connectors simplify maintenance and reduce downtime.

Frequently Asked Questions (FAQ)

-

What is the primary function of the PR6426/010-140 sensor?

It is used to measure vibration, displacement, and shaft position in rotating machinery. -

Can the PR6426 be used in explosive environments?

Yes, it is available with ATEX certification for hazardous area applications. -

What is the maximum temperature the sensor can withstand?

The sensor operates up to +180°C and can be stored at temperatures up to +200°C. -

Is the probe length customizable?

Yes, while the standard is 140 mm, custom lengths can be provided upon request. -

How does the sensor connect to monitoring systems?

It connects via the CON010 connector and outputs a voltage signal. -

What type of maintenance is required?

The sensor is virtually maintenance-free due to its non-contact operation and durable design. -

What industries commonly use this sensor?

Power generation, oil & gas, petrochemical, steel, cement, and water treatment sectors. -

Can it measure both axial and radial displacement?

Yes, depending on installation, it can monitor either axial or radial movement. -

Is this sensor compatible with Bently Nevada systems?

It can be integrated with certain systems using conversion modules, though primarily optimized for Epro/Vibro-Meter systems. -

What is the weight for this model?

1.4 kg.

Related Models (Same Series / Functionality)

| Model | Probe Diameter | Measurement Range | Special Feature |

|---|---|---|---|

| PR6426/000-030+CON021 | 8 mm | 0–2 mm | Compact version for tight spaces |

| PR6426/010-140+CON041 | 32 mm | 0–4 mm | Alternative connector option |

| PR6426/005-030+CON031 | 25 mm | 0–3 mm | Mid-size sensor for standard use |

| PR6426/010-000+CON041 | 32 mm | Custom range | Custom output configuration |

| PR6426/012-100+CON011 | 16 mm | 0–2 mm | Used in gas turbine monitoring |

| PR6426/014-140+CON031 | 32 mm | 0–4 mm | Enhanced shielding for EMI environments |

Popular Models from the Same Brand (Epro / Brüel & Kjær Vibro)

| Model | Function | Application | Output Type |

|---|---|---|---|

| PR9268/201-000 | Vibration velocity sensor | Pumps, motors, fans | IEPE (accelerometer) |

| MMS3120/022-100 | Monitoring module | Turbine and compressor systems | Analog + Digital |

| CON021 | Signal converter | For PR642x sensor series | Passive conversion |

| MMS6120 | Vibration monitoring system | Plant-wide vibration analysis | Multi-channel output |

| PR6423/000-031+CON021 | Eddy current sensor | General-purpose machine monitoring | Voltage output |

| MMS6410 | Compact monitoring module | Used in distributed monitoring setups | Ethernet/Serial |

Excellent PLC

Excellent PLC