| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

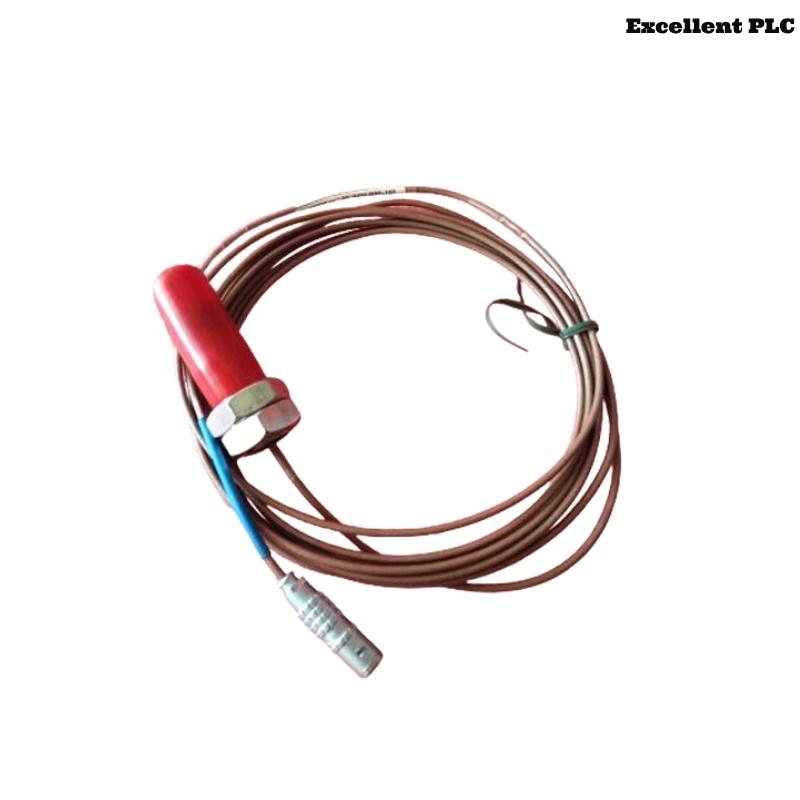

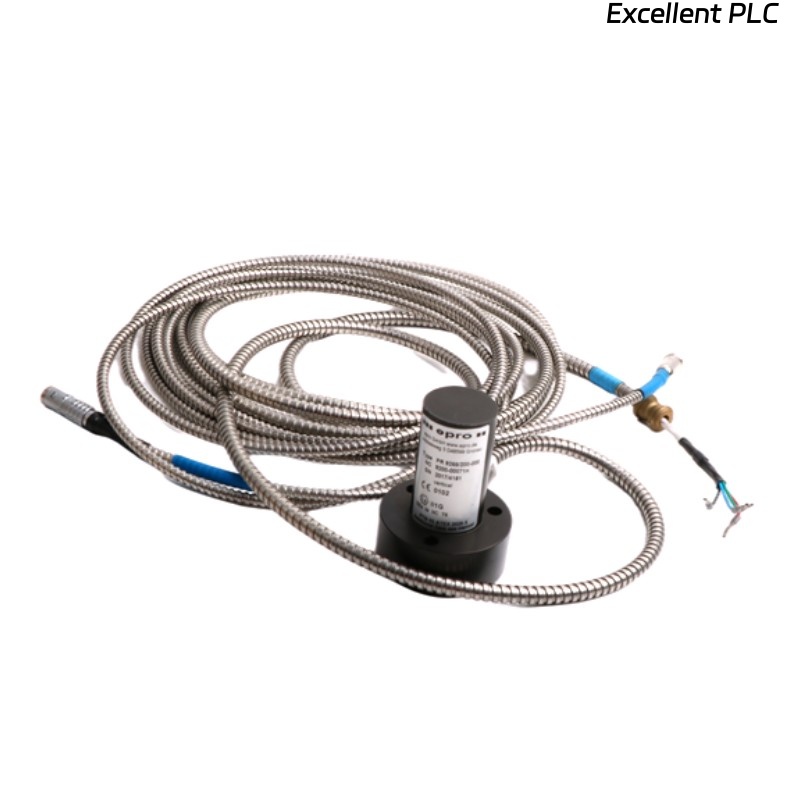

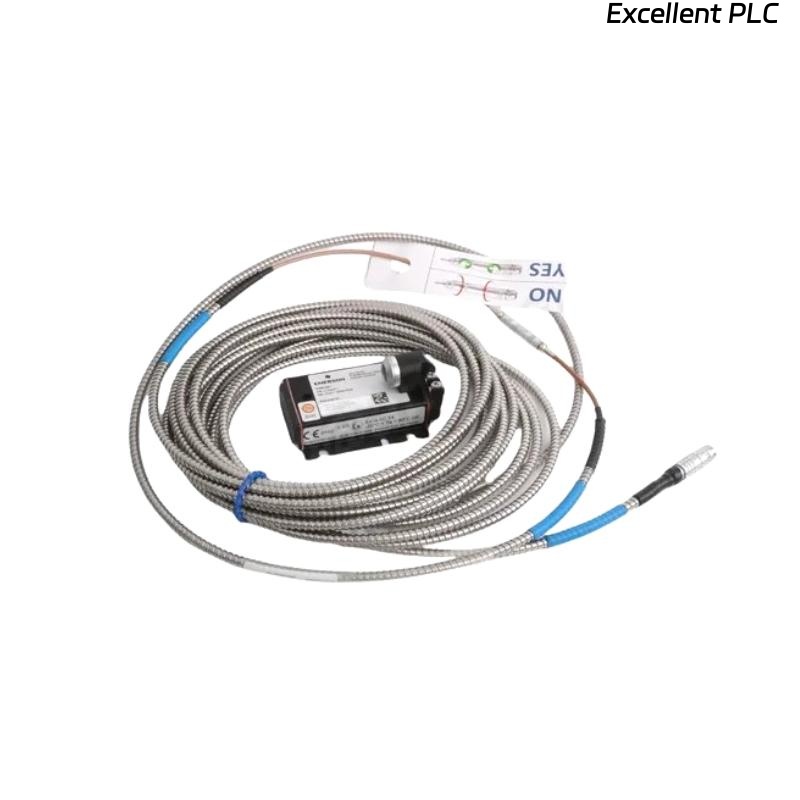

The Epro PR6453/110-101 is a high-precision eddy current displacement sensor engineered to monitor the axial and radial shaft movements in rotating machinery. With a probe diameter of 12.5mm, this sensor is part of Epro’s trusted PR6453 series, widely used in vibration monitoring, condition monitoring, and machinery protection systems in critical industrial applications.

As a non-contact proximity probe, it operates based on the eddy current principle, generating a high-frequency magnetic field to detect metal surface proximity. The sensor is compatible with Epro’s CON series extension cables and associated signal converters (e.g., CON041 or CON011), offering seamless integration with industry-standard monitoring systems such as the MMS6000 and VM600 platforms.

Built for harsh environments, the PR6453/110-101 is designed to function reliably under high temperatures, pressures, and vibrations, making it ideal for deployment in steam turbines, compressors, generators, and large pumps across the oil & gas, petrochemical, and power sectors.

Product Specifications

| Parameter | Description |

|---|---|

| Model | PR6453/110-101 |

| Sensor Type | Eddy Current Proximity Probe |

| Measuring Principle | Non-contact, based on eddy current induction |

| Sensor Head Diameter | 12.5 mm |

| Sensing Range | Typically 0.25 mm to 4.0 mm (linear range) |

| Linear Range | ±2 mm (around nominal gap) |

| Sensitivity | 7.87 mV/μm (typical, depending on calibration) |

| Output Signal | Analog voltage, proportional to displacement |

| Frequency Response | 0 to 10 kHz (-3 dB) |

| Material (Sensor Tip) | Stainless steel, PEEK insulation |

| Mounting Thread | M14x1.5 standard (other options available on request) |

| Cable Connection | Coaxial connector, compatible with CON041/CON011 |

| Operating Temperature | -35°C to +180°C |

| Shock Resistance | Up to 100 g |

| Vibration Resistance | Up to 20 g (10–2000 Hz) |

| Ingress Protection | IP67 |

| Weight | 0.8 kg |

| Compatible Extension Cable | Epro CON041/CON011 (with matched calibration) |

| Certifications | CE, ATEX (Ex approval available), RoHS |

Applications

The Epro PR6453/110-101 eddy current probe is widely deployed in rotating machinery monitoring where precision displacement measurement is vital. Key applications include:

-

Steam and Gas Turbines: For axial thrust and shaft vibration measurement.

-

Centrifugal Compressors: To monitor shaft position and dynamic behavior.

-

Electric Generators and Motors: Ensures shaft alignment and vibration compliance.

-

Industrial Pumps and Fans: Helps in detecting early signs of misalignment or bearing wear.

-

Gearboxes and Expanders: Measures gear shaft displacement and condition trends.

-

Condition Monitoring Systems: Integrated into online and offline diagnostic platforms for predictive maintenance.

Its robustness and high-temperature tolerance make it ideal for use in hazardous environments like oil refineries, petrochemical plants, and power generation units.

Product Advantages

-

High Precision Measurement: Provides micron-level accuracy for displacement and vibration monitoring.

-

Non-Contact Sensing: Eliminates mechanical wear and extends service life.

-

Wide Operating Temperature: Withstands extreme industrial conditions up to 180°C.

-

Standardized Design: Compatible with Epro’s signal converters and MMS systems.

-

Rugged Build: Stainless steel construction with IP67 protection for durability.

-

Quick Installation: Standard mounting threads and pre-calibrated system compatibility reduce setup time.

-

Maintenance-Friendly: Remote monitoring capability reduces manual inspection requirements.

-

Customizable Lengths: Probe lengths can be adjusted based on installation needs.

-

Proven Reliability: Long-term performance in critical industries like oil & gas and power.

-

Certified for Hazardous Areas: Ensures compliance with international safety standards.

Frequently Asked Questions (FAQ)

-

What is the purpose of the PR6453/110-101 sensor?

It measures the displacement and vibration of metallic rotating shafts using a non-contact eddy current principle. -

Can this sensor operate at high temperatures?

Yes, it supports temperatures up to +180°C, making it suitable for high-temperature environments like turbines. -

What monitoring systems is it compatible with?

It works with Epro’s MMS6000, VM600, and other systems that accept eddy current sensor input via CON041/CON011. -

What is the measuring range of this sensor?

The linear measuring range is typically ±2 mm around a nominal gap of 2 mm. -

Does the sensor need calibration?

Yes, calibration is performed with a matched converter and extension cable to ensure accuracy. -

What is the thread type of the sensor?

The standard mounting thread is M14x1.5, but other thread types can be customized. -

Can I install it in explosive environments?

Yes, ATEX-certified versions are available for hazardous area installations. -

What type of materials can it measure?

It is optimized for ferromagnetic metals such as steel and iron shafts. -

What is the output signal type?

It provides an analog voltage output that is proportional to displacement. -

What happens if the probe is damaged?

It must be replaced and re-calibrated with its matching cable and converter for accurate operation.

Related Models (Same Series or Application)

| Model Number | Description | Probe Tip Diameter | Linear Range |

|---|---|---|---|

| PR6453/110-000 | Standard 8 mm probe, general use | 8 mm | ±1 mm |

| PR6453/110-030 | 5 mm tip diameter, for tighter spaces | 5 mm | ±0.75 mm |

| PR6453/120-101 | 12.5 mm tip, armored cable version | 12.5 mm | ±2 mm |

| PR6453/130-000 | 16 mm tip, extended range sensor | 16 mm | ±3 mm |

| PR6423/002-030 | Eddy current sensor, smaller tip | 5 mm | ±0.5 mm |

| PR6424/010-040 | High-temp sensor for turbine applications | 10 mm | ±2 mm |

Popular Models from the Same Brand (Epro / Emerson)

| Model Number | Description | Category |

|---|---|---|

| MMS6120/022-100 | Machinery Monitoring System (2-channel) | Monitoring System |

| PR6423/000-031 | Eddy Current Probe, compact variant | Vibration Sensor |

| CON041 | Signal Converter for eddy current sensors | Signal Converter |

| CON021 | Extension Cable, compatible with PR6423 series | Cable |

| MMS6312 | 12-channel vibration monitoring rack | Monitoring Rack |

| MMS6410 | High-density vibration monitoring module | Vibration Monitoring Card |

Excellent PLC

Excellent PLC