| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

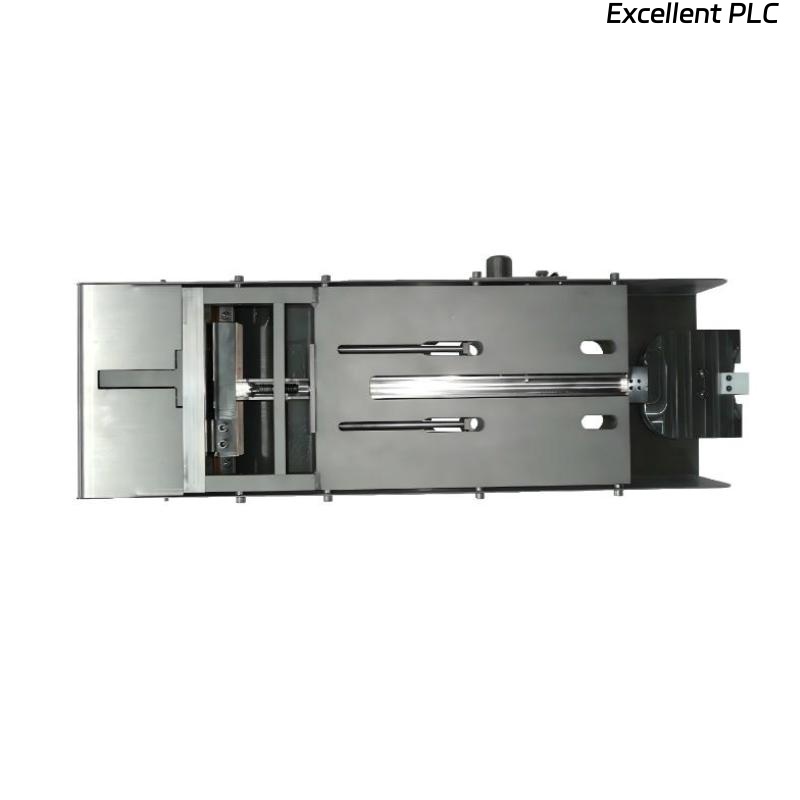

The Epro PR6453/361-000 12.5mm Eddy Current Sensor is a precision-engineered, non-contact displacement and vibration probe developed for continuous monitoring of rotating and reciprocating machinery. Designed to deliver high accuracy, excellent temperature stability, and long-term reliability, this sensor is a vital component for predictive maintenance and machine protection systems.

Based on the eddy current principle, the PR6453/361-000 generates an electromagnetic field that induces eddy currents in a conductive target surface. The resulting change in impedance is linearly proportional to the target’s displacement or vibration amplitude. This data is then processed by compatible Epro converter modules—typically CON021 or CON041—to produce precise and stable output signals used by machine monitoring and control systems.

With a 12.5 mm sensor head, this model provides excellent balance between measurement range and physical compactness. It is particularly suited for applications where both shaft vibration and relative displacement need to be measured with high precision. The sensor’s rugged stainless-steel body and hermetically sealed design ensure reliable operation in harsh industrial environments, including high temperatures, oil exposure, and areas subject to strong mechanical vibration.

The PR6453/361-000 is widely used in turbines, compressors, pumps, and generators. It forms part of Epro’s PR6453 series of sensors—renowned for their stability, linearity, and compatibility with Epro’s advanced MMS monitoring systems.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | PR6453/361-000 |

| Manufacturer | Epro |

| Sensor Type | Eddy Current Displacement and Vibration Probe |

| Measurement Principle | Non-contact electromagnetic induction |

| Sensor Head Diameter | 12.5 mm |

| Shipping Weight | 3 kg |

| Measurement Range | Typically 0.5 mm to 2.0 mm |

| Frequency Response | 0.5 Hz to 20 kHz |

| Linearity | ≤ ±1% of full-scale output |

| Sensitivity | Factory-calibrated with CON021/CON041 converter |

| Compatible Converters | CON021, CON041 |

| Power Supply (via converter) | +24 VDC nominal |

| Operating Temperature | -35°C to +180°C |

| Storage Temperature | -40°C to +200°C |

| Target Material | Conductive metallic surfaces such as steel or nickel alloys |

| Mounting Type | Threaded or flange mounting |

| Electrical Connection | Shielded industrial connector |

| Protection Rating | IP65 |

| Insulation Resistance | >10 MΩ at 500 VDC |

| Output Signal | Differential analog voltage |

| Vibration Resistance | 20 g peak, 10–2000 Hz |

| Compliance | CE / ATEX Zone 2 certified |

| Application Environment | Industrial rotating machinery, high-vibration zones |

Applications

The Epro PR6453/361-000 is designed for demanding industrial environments that require high precision in measuring both static and dynamic displacement. It is ideal for use in predictive maintenance systems and real-time vibration monitoring of rotating equipment.

Typical applications include:

-

Steam and Gas Turbines: Monitoring shaft vibration and axial displacement for early fault detection.

-

Compressors: Continuous supervision of bearing and rotor behavior to prevent mechanical damage.

-

Electric Motors and Generators: Detecting shaft position deviation and imbalance for system protection.

-

Industrial Pumps: Measuring vibration amplitude to detect cavitation or bearing wear.

-

Gearboxes and Transmission Systems: Monitoring alignment and shaft run-out under dynamic load.

-

Machine Protection Systems: Integration with Epro MMS or similar monitoring systems for automatic alarms and shutdown functions.

By delivering precise, real-time measurement data, the PR6453/361-000 supports condition-based maintenance strategies, significantly reducing unexpected downtime and extending machine life.

Advantages

The Epro PR6453/361-000 12.5mm Eddy Current Sensor offers a combination of precision, robustness, and adaptability that sets it apart from standard industrial probes.

-

High Accuracy: Ensures precise displacement and vibration readings over the full measurement range.

-

Non-Contact Design: Prevents mechanical wear and eliminates friction, enhancing long-term reliability.

-

Excellent Linearity: Provides a stable and repeatable signal across the entire operating range.

-

Wide Temperature Tolerance: Operates reliably in environments up to +180°C.

-

Electromagnetic Shielding: Superior noise immunity for use near high-power equipment.

-

Compact Design: 12.5 mm diameter allows for easy installation in limited mounting spaces.

-

Stable Performance: Maintains calibration accuracy even under fluctuating environmental conditions.

-

Corrosion and Oil Resistance: Suitable for harsh mechanical and oil-rich environments.

-

Easy Integration: Fully compatible with Epro CON021 and CON041 converter systems.

-

Industrial Durability: Withstands strong vibration, temperature variation, and electrical interference.

FAQ

-

What measurement principle does the PR6453/361-000 use?

It uses the eddy current principle to measure displacement and vibration without physical contact. -

Which converters are compatible with this sensor?

The sensor is compatible with Epro CON021 and CON041 converter modules. -

Can it measure both dynamic and static signals?

Yes, it can simultaneously measure dynamic vibration and static shaft position. -

What is the standard output signal type?

It delivers a differential analog voltage signal via the converter unit. -

Is this sensor suitable for high-temperature operation?

Yes, it can continuously operate in environments up to +180°C. -

How does it perform under high electromagnetic interference?

It features robust shielding and differential output to minimize the influence of EMI. -

Can this sensor be used in hazardous or ATEX-certified zones?

Yes, it is certified for ATEX Zone 2 environments. -

What is the typical linearity of this model?

Linearity is maintained within ±1% of full-scale output under calibrated conditions. -

Is it suitable for integration with third-party monitoring systems?

Yes, as long as the output signal from the converter matches the system requirements. -

Does the sensor require recalibration after long-term use?

No, it is factory-calibrated and designed to maintain stability without frequent recalibration.

Related and Series Models

| Model Number | Description |

|---|---|

| PR6453/000-SDR | Standard eddy current probe for general displacement applications |

| PR6453/101-SDR | High-sensitivity model for precise displacement detection |

| PR6453/201-SDR | Temperature-resistant version for turbine and compressor monitoring |

| PR6453/240-101 | Medium-range sensor for dynamic vibration measurement |

| PR6453/341-001 | Compact variant optimized for tight installations |

| PR6453/361-000 | Robust, stable version for continuous heavy-duty monitoring |

Popular Epro Models

| Model Number | Description |

|---|---|

| PR6423/002-030+CON021 | Standard eddy current probe and converter for machinery protection |

| PR6423/005-010 | Compact displacement sensor for confined mounting areas |

| PR6424/01CS | Precision proximity sensor for turbine shaft applications |

| PR6424/014-040+CON021 | Heavy-duty probe-converter combination for industrial systems |

| PR6426/010-020 | Large-range 32 mm eddy current sensor for big shaft monitoring |

| MMS3120/022-100 | Multi-channel machinery monitoring module for predictive maintenance |

Excellent PLC

Excellent PLC