| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

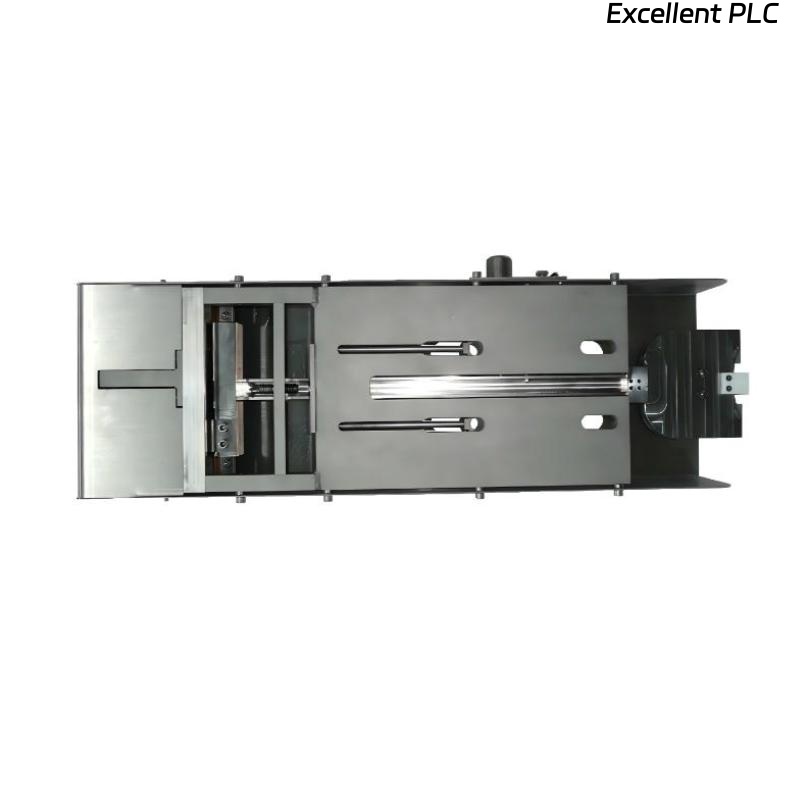

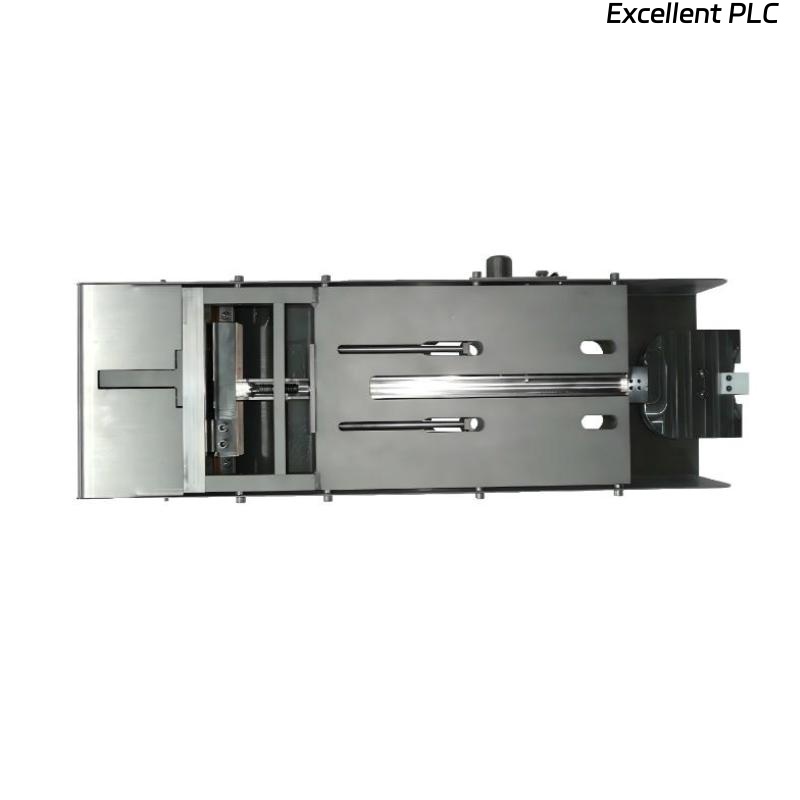

The Epro PR6470/222-110 Probe Pendulum is a high-precision mechanical assembly designed specifically for axial shaft dynamic displacement measurement in critical turbomachinery applications, including steam turbines, gas turbines, hydro turbines, compressors, pumps, and fans. It serves as an intermediate mechanical interface between the machine shaft and the eddy-current displacement sensor, enabling accurate measurements even in conditions where direct installation of a sensor is not possible.

In many rotating machines, the design or mechanical constraints make it impossible to mount eddy-current probes directly onto the measuring collar or rotor. The PR6470/222-110 solves this challenge by transferring the axial movement of the shaft via a precisely balanced pendulum mechanism to a stationary point where the eddy-current sensor can measure the displacement indirectly but with high fidelity.

This probe pendulum is built to meet the most demanding industrial standards. Its robust mechanical structure, high-quality materials, and precise alignment ensure long-term operational stability and minimal signal distortion. When used in conjunction with Epro eddy-current sensors such as the PR6423 or PR6424 series and their associated converters (like CON021), it provides an exceptionally reliable solution for continuous condition monitoring of rotating machinery.

The PR6470/222-110 embodies Epro’s expertise in providing comprehensive monitoring systems that combine mechanical precision with advanced electronic sensing technology, offering unmatched performance under harsh industrial conditions.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | PR6470/222-110 |

| Manufacturer | Epro |

| Product Type | Probe Pendulum for Eddy-Current Sensors |

| Function | Mechanical coupling for indirect axial displacement measurement |

| Compatible Sensors | Epro PR6423 series, PR6424 series |

| Measurement Range | Up to ±4 mm (depending on system setup) |

| Sensitivity | Defined by connected eddy-current probe and converter combination |

| Frequency Response | DC to 5 kHz (mechanical transmission bandwidth) |

| Sensor Mounting Interface | Compatible with Epro 5/8” or 8 mm thread-type sensors |

| Transmission Type | Mechanical lever pendulum system |

| Operating Temperature | -35°C to +150°C |

| Storage Temperature | -40°C to +180°C |

| Materials | Stainless steel and high-grade aluminum alloy |

| Corrosion Protection | Anodized and passivated surfaces |

| Shock Resistance | 30 g peak |

| Vibration Resistance | 20 g peak, 10–2000 Hz |

| Housing Protection | IP65 (when properly assembled with sensor) |

| Sensor Head Diameter | 32 mm compatible adapter |

| Dimensions | 365 × 65 × 113 mm |

| Weight | 4 kg |

| Mounting Type | Rigid flange or mechanical bracket mounting |

| Application Environment | Industrial rotating machinery, turbine housings, and compressor casings |

| Compliance | CE, ATEX Zone 2 suitable configuration with certified sensors |

Applications

The Epro PR6470/222-110 Probe Pendulum is primarily used in turbomachinery monitoring systems where direct measurement of axial displacement using an eddy-current probe is not feasible due to mechanical layout constraints. Its robust and accurate pendulum mechanism provides a mechanical path that mirrors the shaft’s axial motion, allowing eddy-current sensors to measure displacement indirectly with high accuracy.

Typical applications include:

-

Steam and Gas Turbines: For detecting axial shaft displacement and thrust movement during transient operation.

-

Hydro Turbines: Suitable for installations where shaft collars are not accessible for direct sensor placement.

-

Centrifugal Compressors: Provides reliable measurement of rotor position in high-pressure housings.

-

Industrial Pumps: Enables axial displacement monitoring under submerged or sealed operating conditions.

-

Large Electric Motors and Generators: Facilitates indirect sensing of axial position to prevent mechanical wear or bearing damage.

-

Fans and Blowers: Used for condition monitoring in systems where shaft access is limited.

This probe pendulum is particularly valuable in retrofit applications where existing machinery must be equipped with condition monitoring systems without extensive modification.

Advantages

The Epro PR6470/222-110 Probe Pendulum offers a combination of mechanical innovation, compatibility, and durability that makes it a preferred solution in industrial condition monitoring applications.

-

Indirect Measurement Capability: Enables precise shaft displacement monitoring where direct sensor mounting is mechanically impossible.

-

High Accuracy and Repeatability: Ensures faithful transfer of shaft motion to the eddy-current sensor with minimal mechanical hysteresis.

-

Wide Operating Range: Designed to perform effectively across a large displacement range and broad temperature conditions.

-

Mechanical Stability: Pendulum construction resists vibration-induced distortion, ensuring reliable long-term data acquisition.

-

Robust Construction: Manufactured from corrosion-resistant materials for use in harsh industrial environments.

-

Ease of Integration: Fully compatible with Epro eddy-current sensors and monitoring systems.

-

Low Maintenance: Requires minimal mechanical adjustment and maintains calibration over extended service periods.

-

High Vibration Resistance: Suitable for installation on heavy rotating machinery subject to dynamic forces.

-

Compact Design: Allows flexible installation in existing machinery housings without major modifications.

-

Field Proven Reliability: Extensively used in critical process industries such as power generation, oil and gas, and chemical processing.

FAQ

-

What is the main function of the PR6470/222-110 Probe Pendulum?

It serves as a mechanical interface that transfers axial shaft movement to an accessible point where an eddy-current sensor can measure displacement indirectly. -

Which eddy-current sensors are compatible with this probe pendulum?

It is designed for use with Epro PR6423 and PR6424 series sensors, along with their respective converters. -

How is the pendulum motion converted into an electrical signal?

The pendulum transfers shaft motion to the proximity sensor, which then converts it into an electrical signal proportional to displacement. -

Does it affect the accuracy of the eddy-current sensor?

No, it is designed with precision bearings and low mechanical backlash to ensure accurate motion transfer without signal distortion. -

Can it operate in high-temperature environments?

Yes, it supports continuous operation at temperatures up to +150°C, making it suitable for turbines and compressors. -

How is the probe pendulum mounted?

It can be flange-mounted or bracket-mounted directly to the turbine or compressor casing for stable alignment. -

What is the mechanical transmission range of this model?

It supports axial displacement measurements of up to ±4 mm, depending on the configuration of the connected sensor. -

Is the PR6470/222-110 suitable for use in ATEX-certified installations?

Yes, when paired with an ATEX-certified Epro sensor and converter, it can be safely used in Zone 2 hazardous areas. -

Does the pendulum introduce mechanical delay or lag in signal transmission?

No, the system is designed to provide instantaneous mechanical response, maintaining signal accuracy across dynamic conditions. -

How is calibration achieved when integrating this unit?

Calibration is performed via the connected eddy-current sensor and converter, ensuring system-level accuracy after installation.

Related and Series Models

| Model Number | Description |

|---|---|

| PR6470/000-110 | Standard probe pendulum for general turbine monitoring applications |

| PR6470/111-110 | Compact pendulum model for confined mechanical spaces |

| PR6470/222-110 | Extended-range version for wide axial displacement measurement |

| PR6470/300-000 | Heavy-duty pendulum assembly for high-vibration environments |

| PR6470/400-110 | High-temperature-resistant pendulum for steam turbine systems |

| PR6470/500-120 | Customized version for non-standard sensor mounting applications |

Popular Epro Models

| Model Number | Description |

|---|---|

| PR6423/002-030+CON021 | Standard eddy-current sensor system for shaft vibration monitoring |

| PR6424/014-040+CON021 | Heavy-duty proximity probe and converter set for turbine applications |

| PR6426/010-020 | Large 32 mm eddy-current sensor for extended displacement range |

| PR6453/341-001 | Medium-range 12.5 mm vibration and displacement probe |

| PR6453/361-000 | High-precision probe for axial shaft vibration monitoring |

| MMS3120/022-100 | Multi-channel machine monitoring module for Epro protection systems |

Excellent PLC

Excellent PLC