| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

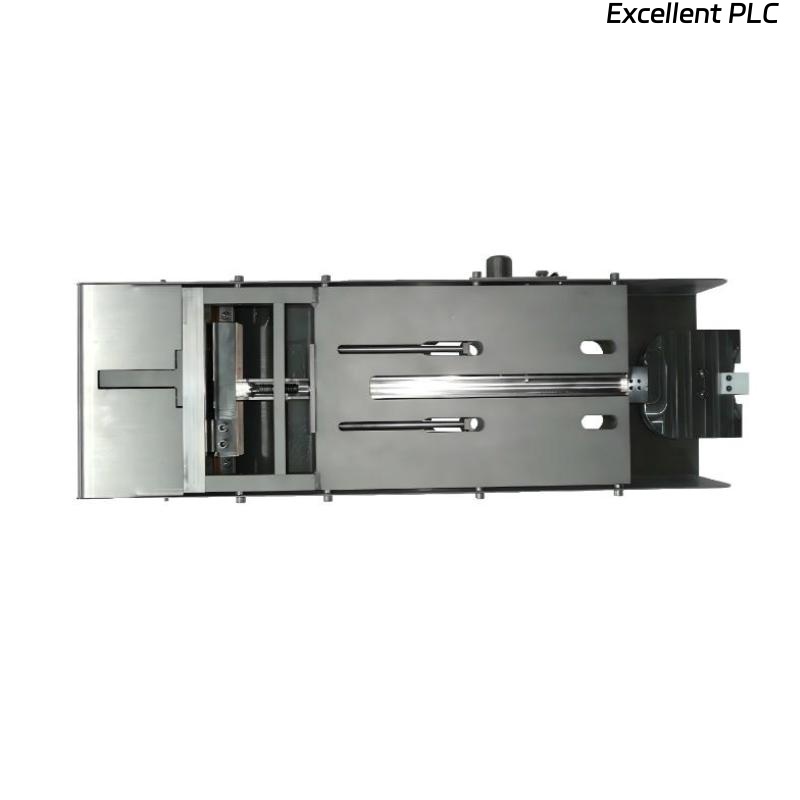

The Epro PR6470/223-120 Probe Pendulum is a precision-engineered mechanical component designed for indirect axial displacement measurement in rotating machinery. It acts as a mechanical transmission interface between the machine shaft and an eddy-current proximity sensor, enabling accurate monitoring of axial movement in machines where direct installation of the probe is not mechanically feasible.

This model belongs to the Epro PR6470 series, a family of probe pendulums widely used in turbomachinery, including steam turbines, gas turbines, hydro turbines, compressors, and pumps. The PR6470/223-120 transfers the dynamic movement of the rotor or thrust collar to a stationary position where the eddy-current sensor can accurately detect and measure the displacement.

The mechanical pendulum mechanism ensures high linearity and negligible hysteresis, allowing faithful transmission of motion to the sensor. The result is a reliable signal that reflects the actual shaft displacement or thrust position under real operating conditions. The system is particularly effective in applications where direct probe access is restricted by machine geometry, pressure housings, or high-temperature zones.

With its robust stainless steel and anodized aluminum construction, the PR6470/223-120 is resistant to corrosion, vibration, and thermal stress. It is designed to work seamlessly with Epro’s PR6423 or PR6424 sensor families and their respective CON021 converter modules, forming a complete and accurate measurement chain for industrial condition monitoring and protection systems.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | PR6470/223-120 |

| Manufacturer | Epro |

| Product Type | Probe Pendulum for Eddy-Current Sensors |

| Function | Mechanical interface for axial shaft displacement measurement |

| Compatible Sensors | Epro PR6423 and PR6424 series |

| Measuring Range | ±4 mm (depending on sensor configuration) |

| Frequency Response | DC to 5 kHz mechanical bandwidth |

| Transmission Principle | Precision mechanical pendulum linkage |

| Sensitivity | Defined by the connected eddy-current probe |

| Linear Error | < ±1% of full-scale deflection |

| Operating Temperature | -35°C to +150°C |

| Storage Temperature | -40°C to +180°C |

| Materials | Stainless steel, anodized aluminum alloy |

| Corrosion Resistance | Surface-treated and passivated |

| Housing Protection | IP65 (fully assembled system) |

| Shock Resistance | 30 g peak |

| Vibration Endurance | 20 g peak, 10–2000 Hz |

| Mounting Configuration | Rigid flange or mechanical bracket |

| Sensor Mount Interface | Compatible with 5/8″ or 8 mm thread-type Epro probes |

| Dimensions | 365 × 65 × 113 mm |

| Weight | 4 kg |

| Certification | CE compliant, suitable for ATEX Zone 2 installations (with certified sensors) |

| Application Environment | Steam/gas/hydro turbines, compressors, pumps, industrial fans |

| Maintenance | Minimal; periodic mechanical alignment verification recommended |

Applications

The Epro PR6470/223-120 Probe Pendulum is a key component in machine condition monitoring systems where direct eddy-current probe placement on the rotor surface is impossible or unsafe. It enables indirect yet highly accurate displacement measurements, which are crucial for the detection of axial thrust movement, shaft displacement, and rotor positioning.

Typical applications include:

-

Steam and Gas Turbines: Monitoring axial shaft movement under transient and steady-state conditions.

-

Hydroelectric Turbines: Measuring displacement where the rotor is enclosed in a pressurized or fluid-filled housing.

-

Centrifugal Compressors: Providing axial position feedback in high-pressure or sealed environments.

-

Industrial Pumps: Enabling non-invasive monitoring of rotor thrust and axial bearing condition.

-

Large Electric Motors: Supporting preventive maintenance by tracking rotor alignment and movement.

-

Fans and Blowers: Allowing accurate displacement monitoring even when direct sensor access is limited.

The PR6470/223-120 is particularly valuable in retrofit installations, as it provides an effective method to upgrade existing machinery with advanced monitoring capabilities without major modifications to the machine structure.

Advantages

The Epro PR6470/223-120 provides several advantages that make it an essential solution in modern turbomachinery diagnostics and protection systems.

-

Indirect Measurement Capability: Ideal for machinery with limited access or structural restrictions preventing direct probe installation.

-

High Measurement Fidelity: Precisely transmits shaft motion to the sensor without mechanical distortion or lag.

-

Wide Dynamic Range: Supports accurate measurement of both small and large axial movements.

-

Superior Mechanical Stability: Built to operate reliably under continuous vibration and thermal stress.

-

Corrosion-Resistant Design: Constructed from treated metals for use in humid, oil-rich, or chemically aggressive environments.

-

Easy Integration: Directly compatible with Epro’s standard eddy-current sensors and signal converters.

-

Maintenance-Free Operation: No lubrication or periodic adjustments required under normal service conditions.

-

Customizable Mounting: Supports flange or bracket installation based on specific machine layouts.

-

High-Temperature Tolerance: Suitable for use in turbine and compressor housings where ambient temperature exceeds 100°C.

-

Proven Industrial Reliability: Extensively used across the power generation, petrochemical, and heavy industrial sectors for reliable long-term monitoring.

FAQ

-

What is the core function of the PR6470/223-120 Probe Pendulum?

It transfers the axial motion of the machine shaft to a fixed point, allowing an eddy-current probe to measure the displacement indirectly. -

Which sensors can be used with this pendulum?

The PR6470/223-120 is compatible with Epro PR6423 and PR6424 eddy-current sensors. -

What is the typical measuring range supported by this model?

It provides accurate transmission for axial displacements up to ±4 mm, depending on the installed sensor. -

Does the pendulum affect the response time of the measurement?

No, the pendulum’s mechanical design ensures immediate motion transfer with negligible delay. -

How is the pendulum connected to the machine structure?

It is mounted using a rigid flange or bracket to maintain alignment with the machine’s axial axis. -

Is the PR6470/223-120 suitable for high-vibration applications?

Yes, it withstands up to 20 g vibration levels and maintains precision under dynamic load conditions. -

What is the temperature range for reliable operation?

The unit operates reliably between -35°C and +150°C, suitable for most industrial turbine environments. -

Does the pendulum require calibration?

Calibration is performed through the connected eddy-current probe and converter after installation, ensuring full system accuracy. -

Can it be used in hazardous areas?

Yes, when used with ATEX-certified Epro probes and converters, it is suitable for Zone 2 hazardous environments. -

What materials are used in its construction?

The body is made from stainless steel and anodized aluminum, providing high mechanical strength and corrosion protection.

Related and Series Models

| Model Number | Description |

|---|---|

| PR6470/000-110 | General-purpose probe pendulum for standard turbine installations |

| PR6470/111-110 | Compact configuration for limited space applications |

| PR6470/222-110 | Extended-range pendulum for wider axial displacement measurement |

| PR6470/223-120 | Enhanced thermal-resistant version for turbine environments |

| PR6470/300-000 | Heavy-duty variant for high-vibration and industrial compressors |

| PR6470/400-120 | Custom-configured pendulum for large hydro turbines and high-load systems |

Popular Epro Models

| Model Number | Description |

|---|---|

| PR6423/002-030+CON021 | Standard eddy-current probe and converter for shaft vibration measurement |

| PR6424/014-040+CON021 | High-performance probe set for turbine displacement monitoring |

| PR6426/010-020 | Large-diameter proximity probe for extended measurement range |

| PR6453/341-001 | 12.5 mm sensor designed for precise vibration detection |

| PR6453/361-000 | Medium-range eddy-current sensor for axial motion measurement |

| MMS3120/022-100 | Machine monitoring system module for multi-channel condition supervision |

Excellent PLC

Excellent PLC