| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

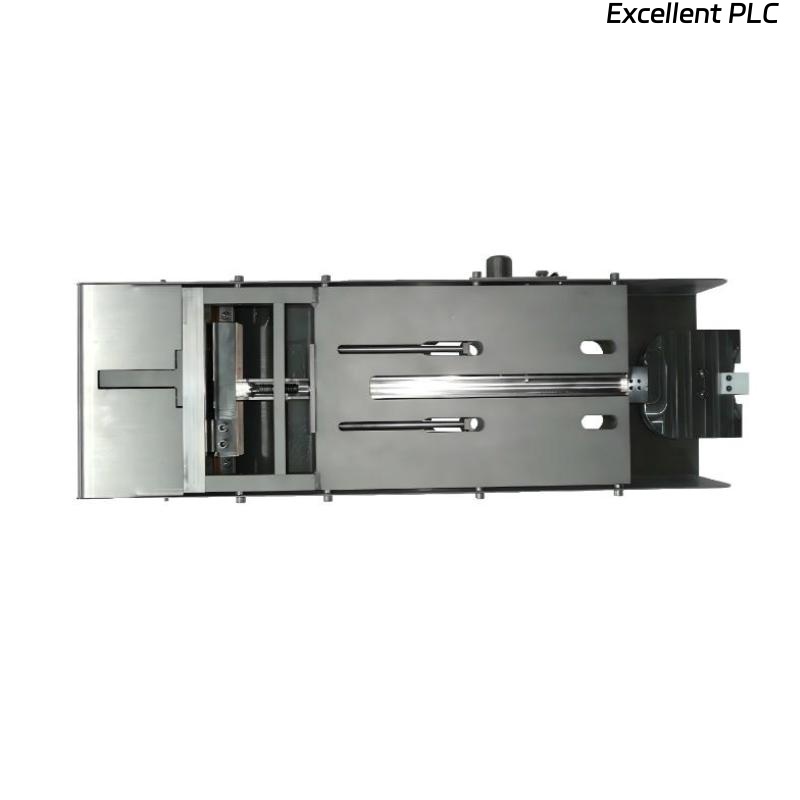

The Epro PR6470/646-120 Probe Pendulum is a precision mechanical assembly designed to enable indirect axial displacement measurement in critical rotating machinery. It acts as an intermediary between the machine shaft and an eddy-current proximity sensor, allowing accurate monitoring of axial shaft movement where direct installation of sensors is mechanically impossible.

This model is part of the PR6470 series, specialized for turbomachinery applications including steam turbines, gas turbines, hydro turbines, compressors, and pumps. The PR6470/646-120 enables measurement at locations where mechanical constraints or harsh environmental conditions prevent direct sensor placement, such as on rotor collars or confined spaces within machinery housings.

The probe pendulum employs a high-precision mechanical lever system to transmit shaft motion to the sensor while maintaining excellent linearity and minimal hysteresis. When used with Epro’s eddy-current sensors (e.g., PR6423 or PR6424) and compatible converters (e.g., CON021), it forms a reliable measurement chain that delivers accurate displacement data under demanding operational conditions.

Constructed from stainless steel and anodized aluminum, the PR6470/646-120 provides robust performance in vibration-intensive environments, high temperatures, and exposure to oil or other industrial fluids. Its compact design allows installation in areas with limited space while maintaining optimal mechanical stability.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | PR6470/646-120 |

| Manufacturer | Epro |

| Product Type | Probe Pendulum for Eddy-Current Sensors |

| Function | Mechanical interface for axial shaft displacement measurement |

| Compatible Sensors | Epro PR6423 and PR6424 series |

| Measuring Range | ±4 mm (depending on sensor setup) |

| Frequency Response | DC to 5 kHz (mechanical transmission) |

| Transmission Principle | Precision mechanical pendulum lever system |

| Sensitivity | Determined by connected eddy-current sensor and converter |

| Linearity | < ±1% full-scale deviation |

| Operating Temperature | -35°C to +150°C |

| Storage Temperature | -40°C to +180°C |

| Materials | Stainless steel, anodized aluminum alloy |

| Corrosion Protection | Passivated and surface-treated components |

| Housing Protection | IP65 when assembled with sensor |

| Shock Resistance | 30 g peak |

| Vibration Endurance | 20 g peak, 10–2000 Hz |

| Mounting Type | Flange or mechanical bracket |

| Sensor Mount Interface | Compatible with 5/8” or 8 mm threaded Epro probes |

| Dimensions | 630 × 80 × 195 mm |

| Weight | 12 kg |

| Certification | CE compliant, ATEX Zone 2 with certified sensors |

| Application Environment | Turbines, compressors, pumps, fans, and generators |

| Maintenance | Minimal; occasional mechanical alignment verification recommended |

Applications

The PR6470/646-120 Probe Pendulum is essential for indirect axial displacement measurement in applications where direct sensor placement is not feasible. It is widely used in the condition monitoring of turbomachinery, providing accurate real-time measurements of axial shaft movements and rotor thrust.

Key applications include:

-

Steam and Gas Turbines: Monitoring axial displacement for rotor thrust control and vibration analysis.

-

Hydro Turbines: Measuring shaft movement where direct sensor access is restricted due to water housings or flow constraints.

-

Compressors: Providing accurate axial displacement feedback in high-pressure and confined spaces.

-

Industrial Pumps: Measuring rotor thrust to prevent bearing overload and mechanical failure.

-

Electric Generators and Motors: Supporting condition monitoring of axial shaft alignment and movement.

-

Fans and Blowers: Enabling monitoring of axial movement in restricted installation spaces.

The PR6470/646-120 is particularly effective for retrofit installations, allowing existing machinery to be equipped with advanced condition monitoring systems without extensive structural modification.

Advantages

The Epro PR6470/646-120 provides significant benefits in high-precision industrial monitoring:

-

Indirect Measurement Capability: Enables displacement measurement where direct sensor installation is impossible.

-

High Accuracy: Provides precise motion transfer with minimal mechanical distortion.

-

Wide Operating Range: Accommodates both small and large axial movements reliably.

-

Mechanical Stability: Maintains accurate motion transmission under vibration and dynamic forces.

-

Robust Construction: Resistant to corrosion, oil, and high-temperature conditions.

-

Seamless Integration: Works with standard Epro eddy-current sensors and converters.

-

Low Maintenance: Designed for long-term operation without frequent adjustments.

-

Flexible Mounting Options: Can be flange- or bracket-mounted depending on machine geometry.

-

High Thermal Tolerance: Suitable for high-temperature industrial environments.

-

Proven Reliability: Extensively used in turbines, compressors, and pumps for consistent performance.

FAQ

-

What is the function of the PR6470/646-120 Probe Pendulum?

It mechanically transfers axial shaft movement to a sensor-accessible point for indirect measurement. -

Which sensors are compatible with this pendulum?

It is compatible with Epro PR6423 and PR6424 eddy-current sensors. -

What is the measuring range of this model?

It can accurately transmit axial movements up to ±4 mm depending on the connected sensor. -

Does the pendulum introduce signal delay?

No, it transmits shaft motion immediately with minimal mechanical lag. -

How is the pendulum mounted to the machine?

It can be installed using a flange or bracket to maintain precise alignment. -

Can it operate in high-vibration environments?

Yes, it is designed to withstand up to 20 g vibration levels while maintaining accuracy. -

What is the temperature range for operation?

It operates reliably between -35°C and +150°C. -

Does the pendulum need recalibration?

Calibration is performed through the connected eddy-current sensor and converter after installation. -

Is it suitable for ATEX hazardous areas?

Yes, with ATEX-certified sensors and converters, it can be used in Zone 2 environments. -

What materials are used in the construction of this pendulum?

The assembly uses stainless steel and anodized aluminum for high strength and corrosion resistance.

Related and Series Models

| Model Number | Description |

|---|---|

| PR6470/000-110 | Standard probe pendulum for general turbine monitoring |

| PR6470/111-110 | Compact pendulum for restricted spaces |

| PR6470/222-110 | Extended-range pendulum for larger axial displacements |

| PR6470/223-120 | Thermal-resistant version for turbine applications |

| PR6470/300-000 | Heavy-duty pendulum for high-vibration compressors |

| PR6470/400-120 | Hydro turbine-optimized pendulum for large shafts |

Popular Epro Models

| Model Number | Description |

|---|---|

| PR6423/002-030+CON021 | Standard eddy-current probe and converter for shaft vibration monitoring |

| PR6424/014-040+CON021 | High-performance proximity probe system for turbine monitoring |

| PR6426/010-020 | Large 32 mm sensor for extended range axial monitoring |

| PR6453/341-001 | 12.5 mm vibration and displacement sensor for medium-range applications |

| PR6453/361-000 | High-precision sensor for axial shaft movement measurement |

| MMS3120/022-100 | Multi-channel monitoring module for industrial machine protection systems |

Excellent PLC

Excellent PLC