| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

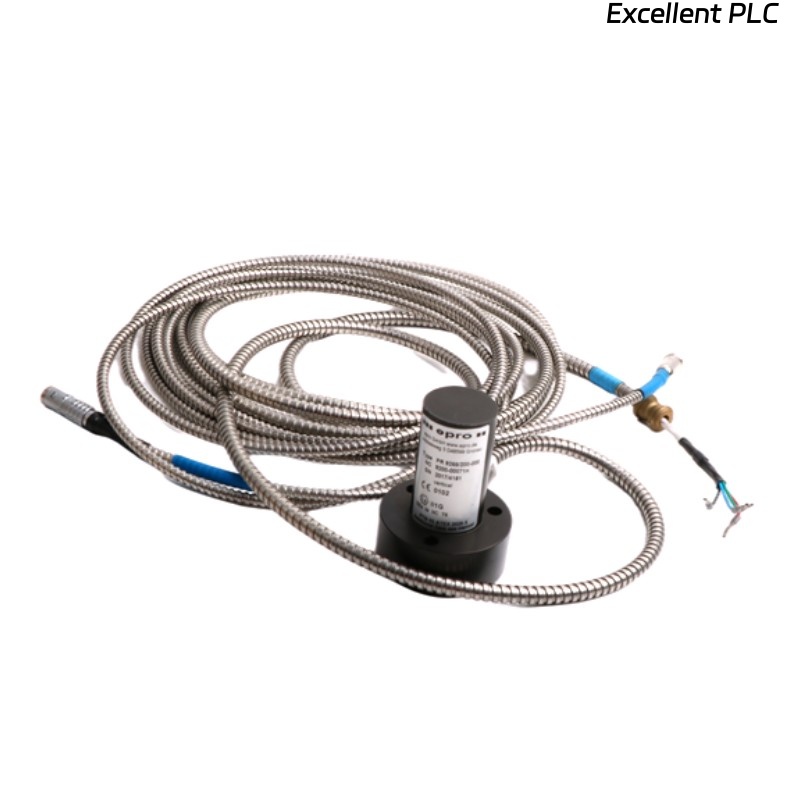

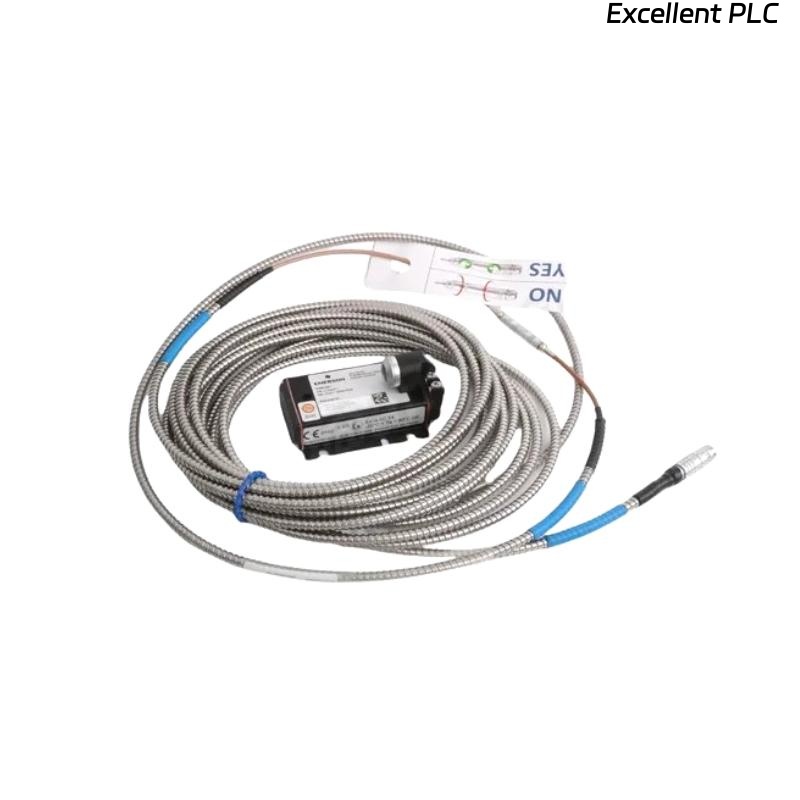

The Epro PR6480/031-000 Eddy Current Sensor is a high-precision non-contact displacement and vibration measurement device, specifically designed for use in industrial machinery monitoring, rotating equipment diagnostics, and condition-based maintenance systems. As part of the renowned Epro PR6480 series, this sensor provides accurate real-time measurement of shaft displacement, vibration, and position in harsh industrial environments.

This model utilizes eddy current technology, which operates on the principle of electromagnetic induction. By generating a high-frequency magnetic field and detecting the response from conductive surfaces, it allows precise measurement of dynamic and static changes without physical contact. The PR6480/031-000 is typically paired with Epro CON0xx converters or signal conditioners, forming a complete monitoring system for turbomachinery, compressors, pumps, turbines, and gearboxes.

Engineered for reliability, this sensor is built using robust stainless-steel housing, ensuring stable operation even under extreme temperature variations, oil mist, and mechanical vibration. It meets international standards for machine protection systems (API 670), making it suitable for integration with advanced monitoring and control platforms like Bently Nevada, HIMA, or Epro MMS systems.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | PR6480/031-000 |

| Product Type | Eddy Current Displacement Sensor |

| Measurement Principle | Non-contact electromagnetic induction |

| Measurement Range | 0 to 2 mm (typical, depending on probe diameter) |

| Linear Range | Up to 80% of full scale |

| Frequency Response | DC to 10 kHz |

| Sensitivity | 7.87 mV/µm (typical) |

| Probe Material | Stainless Steel (AISI 303/304) |

| Target Material | Conductive metal (typically steel) |

| Sensor Tip Diameter | Optional sizes available (e.g., 5 mm, 8 mm, 11 mm) |

| Operating Temperature Range | -35°C to +180°C |

| Storage Temperature Range | -50°C to +200°C |

| Pressure Rating | Up to 10 bar (depending on housing type) |

| Mounting Thread | M10 × 1 or M14 × 1.5 (depending on configuration) |

| Power Supply (via converter) | ±15 VDC or as specified by CON0xx system |

| Output Signal (via converter) | ±10 V or 4–20 mA |

| Cable Type | Coaxial, low-noise, fixed length |

| Cable Length | Typically 5 m or 10 m (custom lengths available) |

| Insulation Resistance | > 10 MΩ at 500 VDC |

| EMC Compliance | EN 61326-1 Industrial Environment |

| Vibration Resistance | 20 g peak (10–2000 Hz) |

| Protection Class | IP67 |

| Housing Material | Stainless Steel |

| Shipping Weight | 3 kg |

| Connection Type | Coaxial connector or integrated cable |

| Compliance Standards | API 670, ISO 10817, CE, RoHS |

Product Applications

The Epro PR6480/031-000 Eddy Current Sensor is used extensively in industrial condition monitoring systems, particularly where high-accuracy, non-contact displacement and vibration measurements are required.

Key application areas include:

-

Turbomachinery Monitoring: Measuring shaft vibration and radial displacement in turbines and compressors.

-

Rotating Equipment Diagnostics: Monitoring bearing and shaft behavior in motors, pumps, and fans.

-

Machine Protection Systems: Integration with vibration and condition monitoring systems (MMS, TSI, or Bently Nevada 3500 series).

-

Predictive Maintenance: Continuous assessment of machine health to prevent unexpected downtime.

-

Aerospace and Power Generation: Monitoring rotor dynamics in jet engines and generator systems.

-

Laboratory and Test Benches: Precision measurement of mechanical motion in controlled research environments.

Product Advantages

-

High Measurement Accuracy: Provides precise non-contact measurement with micro-level resolution.

-

Rugged Industrial Design: Stainless-steel housing ensures resistance to oil, dust, and moisture.

-

Wide Temperature Range: Operates reliably under both cryogenic and high-temperature conditions.

-

Excellent Frequency Response: Suitable for both low-frequency displacement and high-frequency vibration measurements.

-

Compatibility with Epro CON Series: Seamlessly integrates with CON011, CON021, and CON031 converters.

-

API 670 Compliance: Meets global standards for critical machinery protection systems.

-

Low Drift and High Stability: Maintains signal accuracy over long operational periods.

-

Flexible Installation: Available in multiple thread and tip diameter options to suit varied machinery types.

-

Robust EMC Shielding: Immune to electromagnetic interference from nearby industrial equipment.

-

Long Operational Life: Designed for continuous monitoring in harsh environments without recalibration.

FAQ

-

What principle does the PR6480/031-000 sensor use for measurement?

It operates on the principle of eddy current induction to detect changes in distance to a conductive target. -

Which converters are compatible with the PR6480/031-000 sensor?

It is compatible with Epro CON011, CON021, and CON031 signal converters. -

What is the typical measurement range of this sensor?

The standard range is 0–2 mm, though this may vary based on probe configuration and target material. -

Can the sensor be used in high-temperature environments?

Yes, it supports operating temperatures up to +180°C with appropriate cabling and converters. -

Is the sensor suitable for API 670-compliant systems?

Yes, it is fully compliant with API 670 standards for machinery protection systems. -

What output signal formats are available when used with a converter?

The converter provides standard analog outputs of ±10 V or 4–20 mA, depending on system configuration. -

How does the sensor handle electromagnetic interference (EMI)?

It features high-quality coaxial shielding and internal filtering for robust EMI immunity. -

Can it be used to measure both vibration and static displacement?

Yes, it measures both dynamic vibration and static shaft position accurately. -

What materials can be used as targets for this sensor?

The sensor works with any conductive material, with optimal calibration for steel targets. -

Is calibration required for different target materials?

Yes, calibration should be performed using the actual target material for best accuracy.

Related Models (Same Series or Family)

| Model Number | Description | Measurement Range | Operating Temperature | Cable Length |

|---|---|---|---|---|

| PR6480/011-000 | Eddy Current Sensor | 0–1 mm | -35°C to +180°C | 5 m |

| PR6480/021-000 | Eddy Current Sensor | 0–2 mm | -35°C to +180°C | 5 m |

| PR6480/031-000 | Eddy Current Sensor | 0–2 mm | -35°C to +180°C | 10 m |

| PR6480/041-000 | Eddy Current Sensor | 0–4 mm | -35°C to +200°C | 10 m |

| PR6480/050-000 | Eddy Current Sensor | 0–5 mm | -35°C to +200°C | 10 m |

| PR6480/060-000 | Eddy Current Sensor | 0–6 mm | -35°C to +200°C | 10 m |

Popular EPRO Models

| Model Number | Description | Type | Application |

|---|---|---|---|

| PR6423/002-030 | Eddy Current Sensor | Vibration Probe | Shaft vibration monitoring |

| PR6424/010-030 | Eddy Current Sensor | Axial Displacement | Thrust position monitoring |

| MMS3120/022-100 | Monitoring Module | Condition Monitoring | Machine health analysis |

| MMS3125/022-020 | Monitoring Module | Vibration Monitoring | Multi-channel data processing |

| CON021 | Converter Module | Signal Conditioning | Interfaces PR6480 sensors |

| CON011 | Converter Module | Basic Signal Converter | Integration with Epro sensors |

Excellent PLC

Excellent PLC