| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

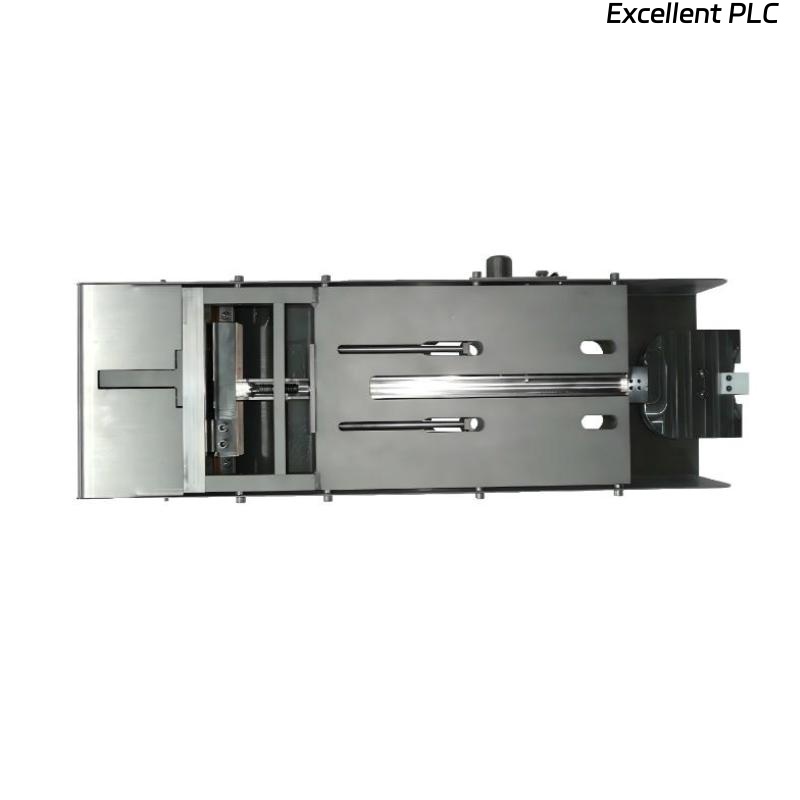

The Epro PR6480/2F1-000 is a high-precision eddy current sensor designed for non-contact displacement, position, and vibration measurements in demanding industrial applications. This sensor operates on the principle of eddy current induction, which allows it to measure distances and detect small displacements without requiring direct physical contact. The PR6480/2F1-000 is ideal for use in critical systems where accuracy, stability, and durability are paramount.

The sensor’s design and performance make it particularly well-suited for applications in machine condition monitoring, vibration analysis, rotating machinery monitoring, and precision alignment. Its versatility and high degree of customization options, such as optional probe diameters and output signals, enable integration into a wide range of industrial systems, including aerospace, automotive, and power generation industries.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | PR6480/2F1-000 |

| Sensing Technology | Eddy current |

| Probe Diameter | Optional (customizable) |

| Shipping Weight | 3 kg |

| Measuring Range | Up to 20 mm (depending on probe) |

| Output Signal | 4-20 mA, 0-10 V (configurable) |

| Temperature Range | -40°C to +120°C |

| Linearity | ≤ ±0.05% of full scale |

| Power Supply | 24 VDC ±10% |

| Housing Material | Stainless steel |

| Enclosure Protection | IP67 |

Applications

The Epro PR6480/2F1-000 is designed for non-contact measurement in a wide variety of industrial applications:

-

Condition Monitoring: Essential in monitoring the health of machines such as motors, turbines, and compressors, providing early fault detection through continuous displacement or vibration monitoring.

-

Vibration Analysis: Used to assess vibrations and oscillations in rotating machinery, aiding in predictive maintenance and avoiding unexpected failures.

-

Machine Alignment: Provides precise measurement in machine alignment processes, helping to maintain proper positioning in industrial systems.

-

Power Generation: Key in measuring rotor-to-stator gaps in turbines and other critical components in power plants, ensuring optimal performance.

-

Aerospace: Vital for ensuring accurate measurements in aerospace components such as engines, for both displacement and vibration monitoring.

-

Automotive: Applied in automotive testing systems to measure displacements in engine components and other high-precision parts.

Advantages

-

Non-Contact Measurement: The PR6480/2F1-000 offers non-contact measurement, reducing wear and tear on machinery and improving the sensor’s longevity.

-

High Precision: With a linearity of ±0.05%, the sensor ensures highly accurate displacement and position measurements.

-

Wide Temperature Range: The sensor operates effectively in harsh environments with temperatures ranging from -40°C to +120°C, ensuring reliable performance across various conditions.

-

Customizable Probe Diameter: The sensor’s probe diameter is optional and can be customized to meet the specific needs of different industrial applications.

-

Durable Construction: Built with stainless steel housing and an IP67 protection rating, the sensor can withstand extreme environments, including exposure to dust, moisture, and corrosive substances.

-

Versatile Output Options: The sensor offers 4-20 mA and 0-10 V output signals, making it highly adaptable for integration with various monitoring and control systems.

-

Low Maintenance: As a non-contact sensor with no moving parts, the PR6480/2F1-000 requires minimal maintenance, reducing downtime and operational costs.

-

Enhanced Signal Integrity: The sensor provides high-quality, low-noise signals, ensuring that the measurements remain accurate even in the presence of electromagnetic interference.

-

Robust for Harsh Environments: With an IP67 rating, the PR6480/2F1-000 is resistant to dust, water, and other contaminants, making it suitable for use in tough industrial environments.

-

Flexibility in Applications: It can be used for various tasks, such as vibration monitoring, machine health diagnostics, and precise alignment in multiple industries.

FAQ

-

What is the maximum measuring range of the Epro PR6480/2F1-000?

The PR6480/2F1-000 can measure up to 20 mm, depending on the configuration of the probe. -

What type of output signals does the PR6480/2F1-000 support?

This sensor supports 4-20 mA and 0-10 V output signals, which can be selected based on application needs. -

What is the operating temperature range for the PR6480/2F1-000?

The PR6480/2F1-000 operates effectively in temperatures ranging from -40°C to +120°C, making it suitable for a variety of industrial environments. -

How precise is the Epro PR6480/2F1-000 sensor?

The sensor offers a linearity of ±0.05%, providing highly accurate displacement and position measurements. -

Can the probe diameter be customized for different applications?

Yes, the probe diameter is optional and can be customized based on specific measurement requirements. -

What industries benefit the most from the PR6480/2F1-000?

The sensor is widely used in industries such as automotive, power generation, aerospace, and oil & gas for precise monitoring of machinery. -

What is the power supply requirement for this sensor?

The sensor operates on 24 VDC, with a tolerance of ±10%. -

Is the PR6480/2F1-000 suitable for use in harsh industrial environments?

Yes, the sensor is built to withstand harsh conditions, with IP67 protection against dust and water ingress, making it ideal for industrial environments. -

How does the PR6480/2F1-000 compare to contact-based sensors?

Unlike contact-based sensors, the PR6480/2F1-000 is non-contact, which reduces wear and tear on machinery and eliminates friction-related errors. -

Can the sensor be used for multi-point measurements?

Yes, the PR6480/2F1-000 can be used in configurations involving multiple sensors for multi-point displacement or vibration measurements.

Similar Models

| Model Number | Description |

|---|---|

| PR6480/2F2-000 | Enhanced version for high-frequency vibration analysis |

| PR6480/2F3-000 | Compact design for tight installations in small machinery |

| PR6480/2F4-000 | High-temperature version for extreme industrial environments |

| PR6480/2F5-000 | Dual-channel sensor for simultaneous multi-point monitoring |

| PR6480/2F6-000 | Long-range sensor for large-scale machinery and turbines |

| PR6480/2F7-000 | High-precision sensor for critical rotor-to-stator gap measurements |

Popular Epro Models

| Model Number | Description |

|---|---|

| PR6480/100-000 | General-purpose sensor for vibration and displacement measurements |

| PR6480/120-000 | Compact sensor for confined spaces and small machines |

| PR6480/140-000 | Standard version for everyday industrial use and condition monitoring |

| PR6480/160-000 | Precision sensor for rotor-stator gap measurements in power plants |

| PR6480/180-000 | High-resolution version for ultra-precise measurements in sensitive systems |

| PR6480/200-000 | Multi-axis sensor for complex machinery and multi-directional measurements |

Excellent PLC

Excellent PLC