| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

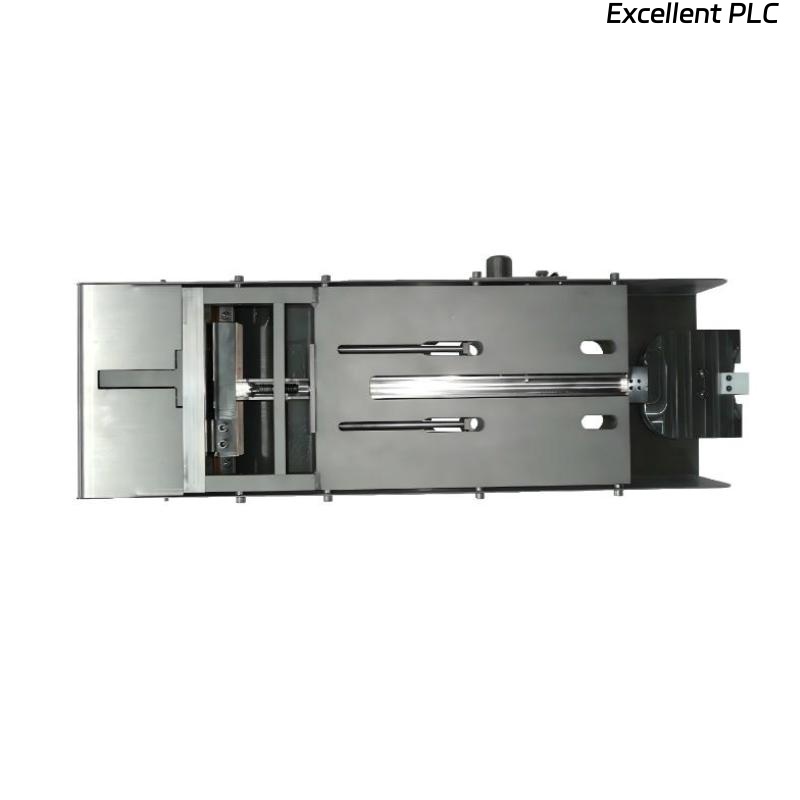

The Epro PR6480/2H1-000 is a state-of-the-art eddy current sensor designed to provide high-precision, non-contact measurements of displacement, vibration, and position. Utilizing eddy current technology, this sensor operates without physical contact, ensuring zero friction and wear during operation. It is especially suitable for applications where contact-based sensors may cause damage or wear over time.

This sensor is optimized for high-performance measurements in industrial monitoring, condition monitoring, and machine health diagnostics. The Epro PR6480/2H1-000 is typically used in environments that require continuous monitoring of critical rotating machinery, ensuring optimal performance and preventing unexpected failures in industries such as aerospace, automotive, power generation, and oil & gas.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | PR6480/2H1-000 |

| Sensing Technology | Eddy current |

| Probe Diameter | Optional (customizable) |

| Shipping Weight | 3 kg |

| Measuring Range | Up to 20 mm (depending on probe) |

| Output Signal | 4-20 mA, 0-10 V (configurable) |

| Temperature Range | -40°C to +120°C |

| Linearity | ≤ ±0.05% of full scale |

| Power Supply | 24 VDC ±10% |

| Housing Material | Stainless steel |

| Enclosure Protection | IP67 |

Applications

The Epro PR6480/2H1-000 sensor is engineered for non-contact measurement applications in several industries, including:

-

Condition Monitoring: Continuously monitors rotating machinery (motors, turbines, and compressors) for signs of wear, misalignment, or imbalance, improving operational efficiency.

-

Vibration Analysis: Provides accurate measurements of vibration levels in industrial machinery, detecting early signs of issues that could lead to failure.

-

Machine Alignment: Ensures precise alignment of machinery parts, reducing the risk of misalignment and mechanical failures.

-

Power Generation: Ideal for rotor-to-stator gap measurement in turbines, helping to maintain system integrity and performance.

-

Aerospace: Monitors critical components in aircraft and space machinery for displacement and vibration, ensuring high precision and reliability.

-

Automotive: Applied in automotive testing systems for detecting displacement and vibration in engine components and other high-precision parts.

Advantages

-

Non-Contact Measurement: The PR6480/2H1-000 eliminates the need for contact with the monitored machinery, avoiding wear, friction, and degradation of components.

-

High Precision: Offering linearity of ±0.05%, the sensor ensures highly accurate and stable measurements, even under challenging operational conditions.

-

Wide Temperature Range: The sensor operates effectively in a temperature range of -40°C to +120°C, making it suitable for use in diverse and harsh environments.

-

Customizable Probe Diameter: The probe diameter can be customized to meet specific measurement needs, making the sensor highly adaptable to various applications.

-

Durable Construction: Constructed with stainless steel housing and an IP67 protection rating, the sensor is resistant to dust, water, and other contaminants, ensuring reliable operation in rugged environments.

-

Flexible Output Options: The PR6480/2H1-000 offers both 4-20 mA and 0-10 V output signals, providing flexibility for integration with various monitoring systems.

-

Low Maintenance: With no moving parts, the sensor requires minimal maintenance, reducing downtime and operational costs.

-

Excellent Signal Integrity: The sensor provides clean, low-noise signals that are resistant to electromagnetic interference, ensuring accurate data collection.

-

Robust for Harsh Environments: The IP67 rating makes the PR6480/2H1-000 suitable for use in dusty, wet, or corrosive environments without compromising performance.

-

Versatile Applications: Its versatility across a wide range of industrial sectors, including vibration analysis, condition monitoring, and precision measurement, makes it a valuable tool in any critical machinery monitoring system.

FAQ

-

What output signals does the PR6480/2H1-000 sensor provide?

The PR6480/2H1-000 supports 4-20 mA and 0-10 V output signals, offering flexibility for integration into various industrial control systems. -

How precise is the PR6480/2H1-000?

This sensor offers linearity of ±0.05% of full scale, providing highly accurate and reliable displacement and vibration measurements. -

What is the operating temperature range of the PR6480/2H1-000?

The PR6480/2H1-000 operates within a wide temperature range of -40°C to +120°C, making it suitable for use in both cold and hot environments. -

What industries typically use the PR6480/2H1-000?

This sensor is widely used in industries such as aerospace, automotive, power generation, and oil & gas for applications like condition monitoring and vibration analysis. -

Can the probe diameter be customized?

Yes, the probe diameter of the PR6480/2H1-000 is optional and can be tailored for specific applications. -

What is the power supply requirement for the sensor?

The PR6480/2H1-000 operates on 24 VDC, with a tolerance of ±10%. -

Is the sensor suitable for multi-point measurements?

Yes, the PR6480/2H1-000 can be used in configurations for multi-point displacement and vibration measurements by integrating multiple sensors. -

How does the PR6480/2H1-000 compare to contact-based sensors?

Unlike contact-based sensors, the PR6480/2H1-000 operates non-contact, eliminating the risks of wear, friction, and mechanical damage during operation. -

What are the main advantages of the PR6480/2H1-000?

The key advantages include non-contact measurement, high precision, customizable probes, and durable construction for harsh environments. -

Is the sensor suitable for use in wet or dusty environments?

Yes, the PR6480/2H1-000 is designed with IP67 protection, making it resistant to dust, water, and other harsh environmental conditions.

Similar Models

| Model Number | Description |

|---|---|

| PR6480/2H2-000 | High-precision version for larger displacement ranges |

| PR6480/2H3-000 | Compact design for installation in confined spaces |

| PR6480/2H4-000 | High-temperature version for extreme conditions |

| PR6480/2H5-000 | Dual-channel version for multi-point measurements |

| PR6480/2H6-000 | Long-range sensor for large-scale machinery monitoring |

| PR6480/2H7-000 | High-frequency version for dynamic measurements |

Popular Epro Models

| Model Number | Description |

|---|---|

| PR6480/100-000 | General-purpose sensor for vibration and displacement monitoring |

| PR6480/120-000 | Compact sensor for small machines and tight spaces |

| PR6480/140-000 | High-performance version for critical applications in power generation |

| PR6480/160-000 | Long-range sensor for large machinery and turbines |

| PR6480/180-000 | High-precision sensor for ultra-sensitive measurements |

| PR6480/200-000 | Multi-axis sensor for complex systems and multi-directional measurements |

Excellent PLC

Excellent PLC