| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

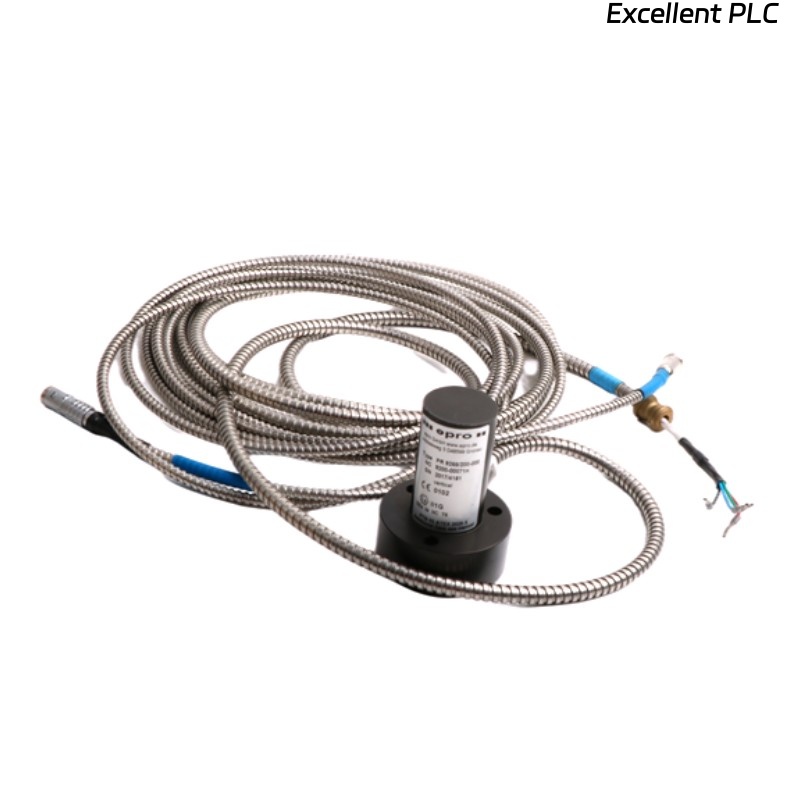

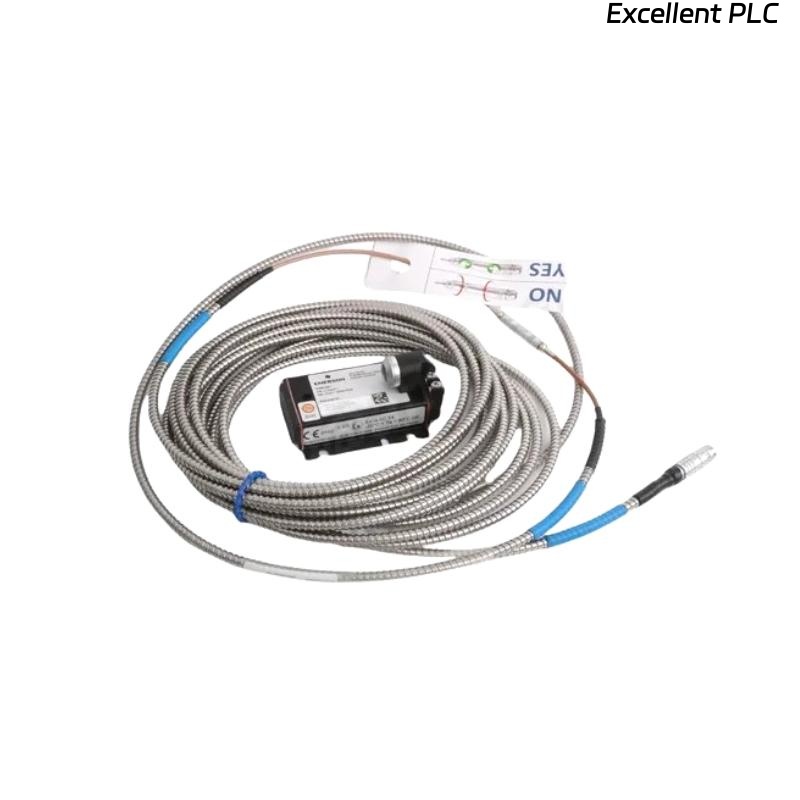

The Epro PR6480/391-000 Eddy Current Sensor is a high-precision, non-contact vibration and displacement probe engineered for demanding industrial environments. It belongs to the Epro PR6480 series, which is renowned for its robust construction, precise linearity, and long-term operational stability. This model is optimized for accurate measurement of shaft vibration, axial displacement, and relative motion in rotating machinery such as turbines, compressors, pumps, and generators.

The PR6480/391-000 operates based on the eddy current measurement principle, using electromagnetic induction to detect the proximity of a conductive surface. When installed near a rotating shaft or metallic target, the sensor produces a voltage signal proportional to the distance or vibration amplitude. When paired with compatible Epro converter units like CON011, CON021, or CON031, it provides a calibrated linear output that can be directly used for machinery protection or condition monitoring systems.

This sensor is designed to meet the stringent requirements of API 670 and ISO 10817 standards. Built with a stainless-steel body and rated IP67 for environmental protection, it is capable of withstanding exposure to oil, dust, and moisture. It is widely used in heavy industries including power generation, petrochemical processing, and mechanical manufacturing, where reliability and accuracy are essential.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | PR6480/391-000 |

| Product Type | Eddy Current Displacement and Vibration Sensor |

| Measurement Principle | Electromagnetic Inductive (Eddy Current) |

| Measurement Range | 0–2 mm typical |

| Linearity | ≤ ±1% of full-scale |

| Sensitivity | 4 mV/μm (typical, depending on converter) |

| Frequency Response | DC to 10 kHz |

| Probe Material | Stainless Steel (AISI 304/316) |

| Target Material | Conductive materials such as steel or aluminum |

| Sensor Head Diameter | Optional |

| Operating Temperature Range | -35°C to +200°C |

| Storage Temperature Range | -50°C to +220°C |

| Pressure Resistance | Up to 10 bar |

| Mounting Thread | M14 × 1.5 |

| Output Signal (via converter) | ±10 V or 4–20 mA |

| Power Supply (via converter) | ±15 VDC nominal |

| Insulation Resistance | ≥10 MΩ at 500 VDC |

| EMC Compliance | EN 61326-1 Industrial Environment |

| Vibration Resistance | 20 g (10–2000 Hz) |

| Shock Resistance | 50 g for 6 ms |

| Protection Class | IP67 |

| Housing Material | Stainless Steel |

| Shipping Weight | 3 kg |

| Connection Type | Coaxial connector or integrated cable |

| Compliance Standards | API 670, ISO 10817, CE, RoHS |

Product Applications

The Epro PR6480/391-000 is designed for precision vibration and displacement measurement in industrial machinery. Its non-contact operation and high-frequency response make it ideal for real-time monitoring of critical components in rotating equipment.

Typical applications include:

-

Turbomachinery monitoring: Shaft vibration and displacement detection in steam and gas turbines.

-

Compressor condition monitoring: Continuous tracking of bearing and shaft movement to prevent mechanical failure.

-

Pump systems: Measurement of rotor position and early detection of imbalance or misalignment.

-

Electric motors and generators: Monitoring axial and radial shaft displacement during startup, operation, and shutdown.

-

Petrochemical equipment: Integration into API 670-compliant machine protection systems for critical rotating assets.

-

Industrial test benches: Used in R&D facilities for performance analysis of rotating components.

Its rugged build and broad environmental tolerance make it suitable for continuous operation in harsh industrial environments, even in the presence of oil mist, dust, or high vibration levels.

Product Advantages

-

Non-contact operation: Ensures zero mechanical wear and long-term reliability.

-

High measurement precision: Accurate displacement detection with excellent repeatability.

-

API 670 compliant: Suitable for use in critical rotating machinery protection systems.

-

Stainless-steel construction: Provides superior resistance to corrosion and harsh environments.

-

Wide operating range: Performs reliably in temperatures from -35°C to +200°C.

-

High immunity to electromagnetic interference: Shielded coaxial design minimizes signal distortion.

-

Fast response time: Suitable for both static displacement and dynamic vibration measurements.

-

Simple integration: Fully compatible with Epro CON-series converter modules.

-

Stable linear output: Maintains consistent sensitivity over long-term operation.

-

Proven field reliability: Extensively used in turbines, compressors, and large industrial drives worldwide.

FAQ

-

What measurement principle is used by the PR6480/391-000?

It uses the eddy current principle, generating an electromagnetic field that varies with the proximity of a conductive target surface. -

Which converter units are compatible with this sensor?

It is compatible with Epro CON011, CON021, and CON031 converters for calibrated voltage or current output. -

Can the PR6480/391-000 measure both vibration and displacement?

Yes, it can measure static displacement and dynamic vibration simultaneously, depending on the signal conditioning setup. -

What type of targets does the sensor require?

The sensor requires a conductive metallic target, preferably steel, for accurate operation. -

What is the maximum frequency response supported by this model?

It provides a wide frequency response from DC up to 10 kHz, ideal for high-speed machinery. -

How does the sensor maintain measurement stability under temperature variations?

The PR6480/391-000 incorporates temperature compensation and precision calibration to ensure stable output over a wide temperature range. -

Can this sensor be used in high-pressure environments?

Yes, it is pressure rated up to 10 bar, suitable for industrial applications involving sealed housings or high mechanical stress. -

Is the PR6480/391-000 resistant to electromagnetic noise?

Yes, it is designed with advanced EMI shielding and complies with EN 61326-1 for industrial electromagnetic compatibility. -

Does the sensor need regular calibration?

Calibration is only required if the sensor is installed on a new target material or when used for precision-critical measurements. -

What is the typical insulation resistance of the probe?

The insulation resistance exceeds 10 MΩ at 500 VDC, ensuring excellent electrical isolation and measurement reliability.

Related Models (Same Series or Family)

| Model Number | Description | Measurement Range | Operating Temperature | Weight |

|---|---|---|---|---|

| PR6480/011-000 | Eddy Current Sensor | 0–1 mm | -35°C to +180°C | 3 kg |

| PR6480/021-000 | Eddy Current Sensor | 0–2 mm | -35°C to +180°C | 3 kg |

| PR6480/051-000 | Eddy Current Sensor | 0–5 mm | -35°C to +200°C | 3 kg |

| PR6480/071-000 | Eddy Current Sensor | 0–7 mm | -35°C to +200°C | 3 kg |

| PR6480/2K1-000 | Eddy Current Sensor | 0–2 mm | -35°C to +200°C | 3 kg |

| PR6480/361-000 | Eddy Current Sensor | 0–2 mm | -35°C to +200°C | 3 kg |

Popular EPRO Models

| Model Number | Description | Type | Application |

|---|---|---|---|

| PR6423/002-030 | Eddy Current Sensor | Displacement Probe | Shaft vibration and clearance measurement |

| PR6423/005-010+CON021 | Eddy Current Sensor System | Integrated Sensor + Converter | Machine protection and monitoring |

| PR6480/051-100 | Eddy Current Sensor | Displacement Probe | Turbine and compressor vibration measurement |

| MMS3120/022-100 | Monitoring Module | Condition Monitoring | Vibration and rotational speed monitoring |

| MMS3125/022-020 | Monitoring Module | Condition Monitoring | Multi-channel vibration and displacement analysis |

| CON021 | Converter Module | Signal Conditioner | Interface unit for PR6480 and PR6423 series sensors |

Excellent PLC

Excellent PLC