| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

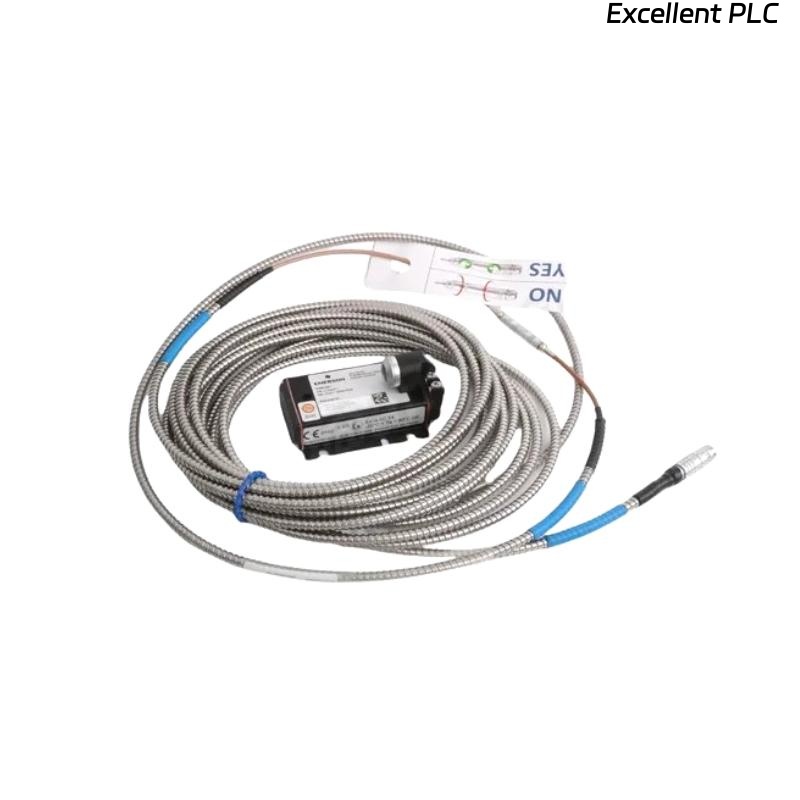

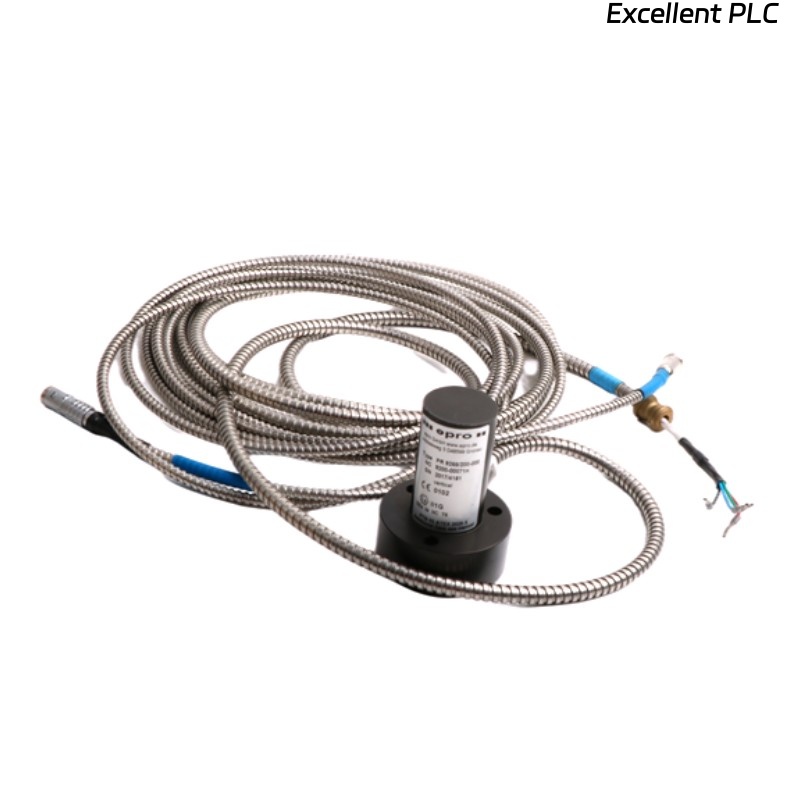

The Epro PR6480/3D1-000 Eddy Current Sensor is a high-performance non-contact displacement and vibration measurement probe, designed specifically for industrial environments where precision, reliability, and durability are critical. As part of the Epro PR6480 series, this model embodies advanced German engineering that ensures accurate and repeatable measurements even in harsh operating conditions such as high temperature, pressure, and vibration.

The sensor operates on the eddy current principle, detecting changes in the distance between its sensing head and a conductive target surface. These changes are converted into proportional voltage signals through compatible Epro converters, such as CON011, CON021, or CON031. This combination provides high-resolution measurements for shaft displacement, axial movement, and vibration amplitude in rotating machinery.

Built with a stainless-steel probe body and sealed to IP67, the PR6480/3D1-000 is suitable for long-term use in oil-contaminated and corrosive environments. It complies with API 670 and ISO 10817 standards, making it an ideal choice for machine protection systems in power generation, petrochemical, and industrial manufacturing sectors.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | PR6480/3D1-000 |

| Product Type | Eddy Current Displacement and Vibration Sensor |

| Measurement Principle | Electromagnetic Induction (Eddy Current) |

| Measurement Range | 0–2 mm typical |

| Linearity | ≤ ±1% of Full Scale |

| Sensitivity | 4 mV/μm (typical, depending on converter) |

| Frequency Response | DC to 10 kHz |

| Probe Material | Stainless Steel (AISI 316) |

| Target Material | Conductive materials such as steel, aluminum, or copper |

| Sensor Head Diameter | Optional |

| Operating Temperature Range | -35°C to +200°C |

| Storage Temperature Range | -50°C to +220°C |

| Pressure Resistance | Up to 10 bar |

| Mounting Thread | M14 × 1.5 or as specified |

| Output Signal (via converter) | ±10 V or 4–20 mA |

| Power Supply (via converter) | ±15 VDC nominal |

| Insulation Resistance | ≥10 MΩ at 500 VDC |

| Vibration Resistance | 20 g (10–2000 Hz) |

| Shock Resistance | 50 g for 6 ms |

| Protection Class | IP67 |

| Housing Material | Stainless Steel |

| Shipping Weight | 3 kg |

| Compliance Standards | API 670, ISO 10817, CE, RoHS, EN 61326-1 Industrial EMC |

Product Applications

The PR6480/3D1-000 Eddy Current Sensor is extensively used for non-contact vibration and displacement measurement in a wide variety of rotating and reciprocating machines. Its ability to deliver high-resolution signals in real-time makes it a vital component in machine protection and condition monitoring systems.

Typical applications include:

-

Steam and Gas Turbines: Measuring shaft vibration, thrust position, and thermal growth.

-

Compressors: Continuous monitoring of rotor displacement and bearing condition.

-

Pumps: Detection of impeller movement, shaft eccentricity, and mechanical misalignment.

-

Generators and Motors: Monitoring of radial shaft vibration during operation and shutdown.

-

Industrial Test Stands: Used in laboratory and R&D setups for performance evaluation of rotating machinery.

-

Petrochemical Equipment: Ideal for process-critical monitoring in refineries and chemical plants under API 670 compliance.

The sensor’s robustness, combined with its temperature tolerance and linear performance, makes it a preferred solution for both new installations and retrofit projects where high accuracy and reliability are required.

Product Advantages

-

Non-contact measurement: Ensures no mechanical wear, providing maintenance-free operation.

-

High accuracy and linearity: Delivers precise readings even under dynamic load and high-speed conditions.

-

Wide temperature range: Operates effectively from -35°C to +200°C, suitable for industrial extremes.

-

Excellent EMC protection: Complies with EN 61326-1, ensuring accurate data in electrically noisy environments.

-

Robust stainless-steel body: Resistant to oil, dust, corrosion, and pressure variations.

-

Easy integration: Fully compatible with Epro’s CON-series converters and MMS condition monitoring systems.

-

Fast response time: Suitable for high-speed vibration and transient event detection.

-

Long-term stability: Minimal signal drift ensures reliable data for continuous monitoring.

-

API 670 and ISO compliant: Meets global standards for machinery protection systems.

-

Proven performance: Trusted across industries for turbine, compressor, and motor monitoring applications.

FAQ

-

What is the operating principle of the PR6480/3D1-000 sensor?

The sensor operates using the eddy current principle, where electromagnetic fields are used to detect the proximity of a conductive surface. -

Which converter modules are compatible with this sensor?

The PR6480/3D1-000 can be paired with Epro CON011, CON021, or CON031 converters for signal processing and calibration. -

Can this sensor measure both static and dynamic displacement?

Yes, it can measure both static displacement (shaft position) and dynamic vibration amplitudes with high precision. -

What types of materials can serve as measurement targets?

It is designed for conductive materials such as steel, aluminum, or copper, ensuring accurate readings with minimal calibration drift. -

How does temperature affect the measurement accuracy?

The PR6480/3D1-000 features internal temperature compensation, maintaining stable output over a broad temperature range. -

Is the sensor suitable for use in high-vibration environments?

Yes, the sensor is designed to operate under continuous vibration levels up to 20 g (10–2000 Hz) and withstand shock loads up to 50 g. -

What kind of environmental protection does the sensor offer?

The sensor is sealed to IP67, making it resistant to oil, dust, and moisture ingress. -

Does it comply with industrial standards for machine protection?

Yes, it fully complies with API 670 and ISO 10817 standards for rotating machinery monitoring. -

How is the sensor signal transmitted to the monitoring system?

The sensor’s analog voltage signal is processed through a compatible converter, which outputs a calibrated voltage or current signal to monitoring systems. -

What is the recommended installation orientation?

It should be installed with the sensing face aligned perpendicularly to the target surface, maintaining the nominal gap specified by the converter setup for optimal linearity.

Related Models (Same Series or Family)

| Model Number | Description | Measurement Range | Operating Temperature | Weight |

|---|---|---|---|---|

| PR6480/011-000 | Eddy Current Sensor | 0–1 mm | -35°C to +180°C | 3 kg |

| PR6480/021-000 | Eddy Current Sensor | 0–2 mm | -35°C to +200°C | 3 kg |

| PR6480/051-000 | Eddy Current Sensor | 0–5 mm | -35°C to +200°C | 3 kg |

| PR6480/071-000 | Eddy Current Sensor | 0–7 mm | -35°C to +200°C | 3 kg |

| PR6480/2K1-000 | Eddy Current Sensor | 0–2 mm | -35°C to +200°C | 3 kg |

| PR6480/391-000 | Eddy Current Sensor | 0–2 mm | -35°C to +200°C | 3 kg |

Popular EPRO Models

| Model Number | Description | Type | Application |

|---|---|---|---|

| PR6423/002-030 | Eddy Current Probe | Displacement Measurement | Shaft vibration and clearance monitoring |

| PR6423/005-010+CON021 | Eddy Current Sensor System | Probe + Converter | Machine protection and condition monitoring |

| PR6480/051-100 | Eddy Current Sensor | Displacement Probe | Turbine and compressor monitoring |

| MMS3120/022-100 | Monitoring Module | Condition Monitoring | Multi-channel vibration analysis |

| MMS3125/022-020 | Monitoring Module | Condition Monitoring | Dynamic vibration and displacement processing |

| CON021 | Converter Module | Signal Conditioner | Interface for PR6480 and PR6423 series sensors |

Excellent PLC

Excellent PLC