| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

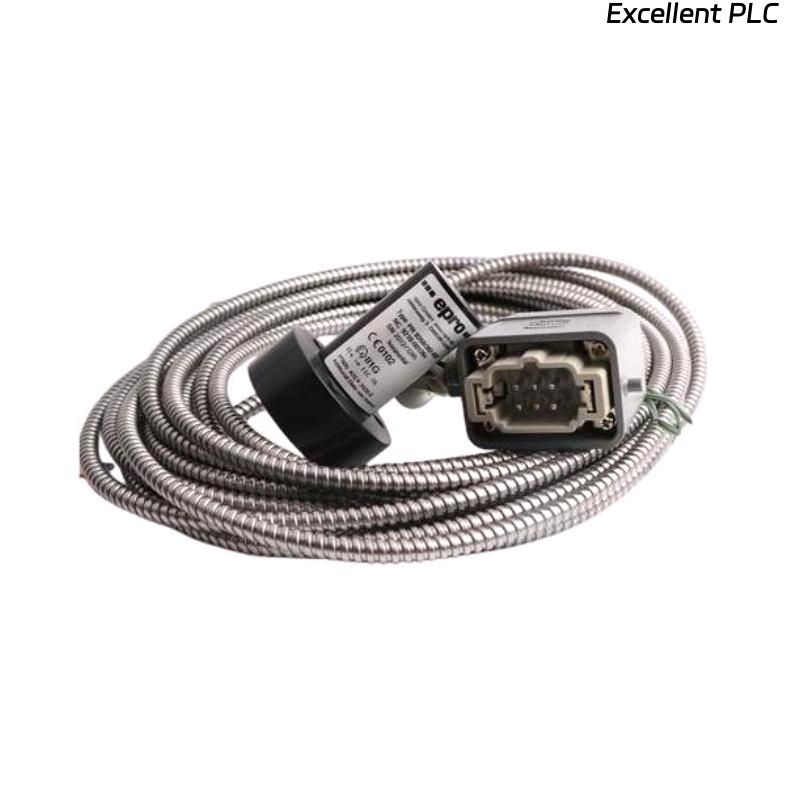

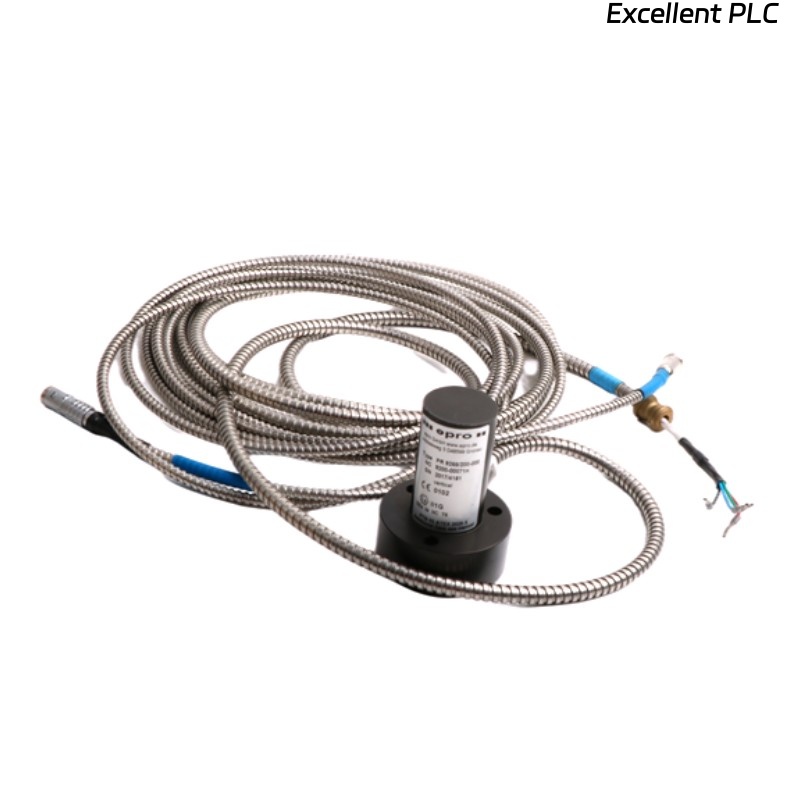

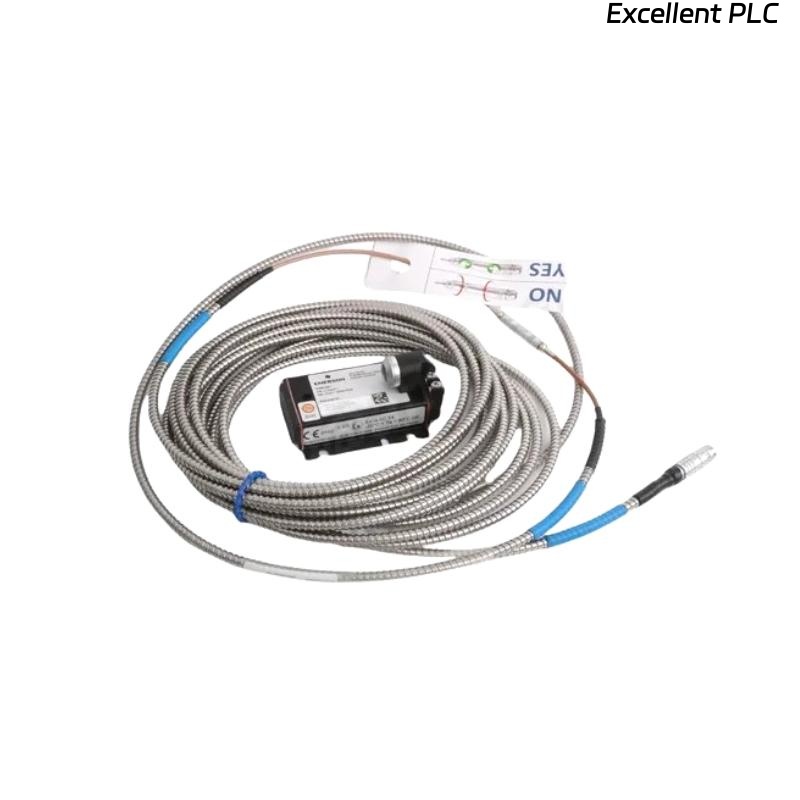

The Epro PR9264/010-000 Electrodynamic Velocity Sensor is a high-precision vibration transducer specifically engineered to measure the vibration velocity of machinery surfaces in industrial environments. It operates on the electrodynamic moving-coil principle, converting mechanical vibration into an electrical signal that is directly proportional to velocity.

This sensor is designed for absolute vibration measurement on non-rotating parts of machinery such as bearing housings, machine casings, or structural components. The PR9264/010-000 provides a pure velocity signal without the need for signal integration or external amplification, ensuring fast, accurate, and reliable vibration monitoring.

As part of the proven Epro PR9264 series, this model is recognized for its mechanical robustness, excellent linearity, and high immunity to environmental interference. The rugged stainless-steel housing and sealed internal components make it suitable for harsh industrial settings such as power generation, oil and gas, petrochemical, and heavy manufacturing industries.

This sensor is frequently integrated with Epro MMS (Machine Monitoring System) platforms for continuous monitoring and protection of turbines, compressors, and large motors. Its self-generating design and wide frequency response make it ideal for both online monitoring and diagnostic applications.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | PR9264/010-000 |

| Product Type | Electrodynamic Velocity Sensor |

| Measurement Principle | Moving Coil (Electrodynamic) |

| Measurement Quantity | Vibration Velocity (mm/s or in/s RMS) |

| Sensitivity | 10 mV/mm/s (±5%) |

| Frequency Range | 10 Hz – 1,000 Hz |

| Resonant Frequency | > 10 Hz |

| Output Signal | Voltage, proportional to vibration velocity |

| Internal Resistance | Approx. 350 Ω |

| Measuring Direction | Axial |

| Maximum Vibration Limit | 20 g (10–2,000 Hz) |

| Shock Resistance | 50 g, 6 ms |

| Operating Temperature Range | -25°C to +100°C |

| Storage Temperature Range | -40°C to +120°C |

| Housing Material | Stainless Steel |

| Mounting Type | Threaded Stud or Magnetic Base |

| Protection Class | IP65 |

| Electrical Connection | 2-pin MIL-C-5015 connector or fixed cable |

| Weight | 0.93 kg |

| Dimensions | 78 × 58 mm |

| Compliance | ISO 10816, API 670, CE, RoHS |

Product Applications

The PR9264/010-000 is designed for industrial vibration monitoring and diagnostics in critical rotating equipment. Its ability to directly measure velocity makes it invaluable for detecting and evaluating machine condition in real time.

Typical Applications Include:

-

Turbines (Steam & Gas): Monitoring casing vibration for imbalance, bearing wear, or shaft misalignment.

-

Compressors: Tracking housing vibration levels to identify resonance or bearing faults.

-

Pumps: Measuring vibration to detect cavitation or mechanical degradation.

-

Motors and Generators: Ensuring smooth operation and early detection of mechanical looseness.

-

Fans and Blowers: Monitoring vibration velocity for dynamic balance and structural resonance.

-

Gearboxes: Identifying wear, looseness, and gear mesh defects.

The PR9264/010-000 is widely used in predictive maintenance systems, where consistent vibration velocity measurement enables early fault detection, minimizes unplanned downtime, and improves equipment reliability.

Product Advantages

-

Direct velocity measurement: Produces a true velocity output without signal integration errors.

-

Self-powered design: Does not require any external power supply or signal conditioning.

-

Robust construction: Stainless steel housing ensures durability and long operational life in harsh environments.

-

High linearity and accuracy: Maintains stable performance over a wide frequency range.

-

Excellent temperature stability: Reliable operation in a wide ambient temperature range.

-

Immunity to EMI/RFI interference: Ensures clean signal output even near high-voltage or electromagnetic equipment.

-

Maintenance-free operation: No active electronics or moving parts requiring service.

-

API 670 and ISO 10816 compliant: Meets global vibration monitoring and protection standards.

-

Simple installation: Mounts easily on flat surfaces with threaded studs or magnetic bases.

-

Proven reliability: Extensively used in Epro MMS monitoring systems worldwide.

FAQ

-

What physical principle does the PR9264/010-000 operate on?

It uses the electrodynamic moving-coil principle, where mechanical vibration induces a voltage proportional to velocity. -

What is the sensitivity value of this model?

The PR9264/010-000 provides a nominal sensitivity of 10 mV/mm/s, ensuring accurate signal output across its frequency range. -

Does this sensor require an external power supply?

No, it is a self-generating sensor and does not need any external power or excitation voltage. -

What type of signal output does it generate?

It produces a voltage signal proportional to the vibration velocity of the machine surface. -

In which direction does the sensor measure vibration?

The standard version measures in the axial direction, with other directional options available upon request. -

Can the sensor be directly connected to an Epro MMS monitoring system?

Yes, it is fully compatible with Epro MMS3000 and MMS6000 series modules. -

What is the frequency response range?

The effective operating frequency range is from 10 Hz to 1,000 Hz, suitable for general machinery vibration monitoring. -

How should the sensor be mounted for optimal performance?

It should be mounted securely using a threaded stud or magnetic base to ensure strong mechanical coupling to the machine surface. -

What is the typical internal resistance of the sensor coil?

The internal resistance is approximately 350 ohms, allowing for standard voltage signal interfacing. -

Is it possible to recalibrate the sensor in the field?

Yes, the sensor can be recalibrated using a reference vibration exciter to verify sensitivity and linearity.

Related Models (Same Series or Family)

| Model Number | Description | Measurement Direction | Sensitivity | Weight |

|---|---|---|---|---|

| PR9264/000-000 | Electrodynamic Velocity Sensor | Axial | 20 mV/mm/s | 3.0 kg |

| PR9264/001-000 | Electrodynamic Velocity Sensor | Axial | 20 mV/mm/s | 3.0 kg |

| PR9264/002-000 | Electrodynamic Velocity Sensor | Radial | 20 mV/mm/s | 3.0 kg |

| PR9264/003-000 | Electrodynamic Velocity Sensor | Horizontal | 20 mV/mm/s | 3.0 kg |

| PR9264/004-000 | Electrodynamic Velocity Sensor | Vertical | 30 mV/mm/s | 3.0 kg |

| PR9264/020-000 | Electrodynamic Velocity Sensor | Axial | 40 mV/mm/s | 3.0 kg |

Popular EPRO Models

| Model Number | Description | Type | Typical Application |

|---|---|---|---|

| PR6423/005-010+CON021 | Eddy Current Sensor System | Displacement Probe + Converter | Shaft vibration and clearance monitoring |

| PR6480/051-000 | Eddy Current Sensor | Non-contact Displacement Measurement | Turbine and compressor shaft vibration |

| PR6424/01CS | Eddy Current Probe | Displacement Transducer | Rotor position and shaft vibration |

| MMS3120/022-100 | Monitoring Module | Condition Monitoring | Multi-channel vibration and speed processing |

| MMS3125/022-020 | Monitoring Module | Machinery Protection | Dynamic vibration signal analysis |

| CON021 | Converter Module | Signal Conditioner | Interface for PR6423 and PR6480 sensor series |

Excellent PLC

Excellent PLC