| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

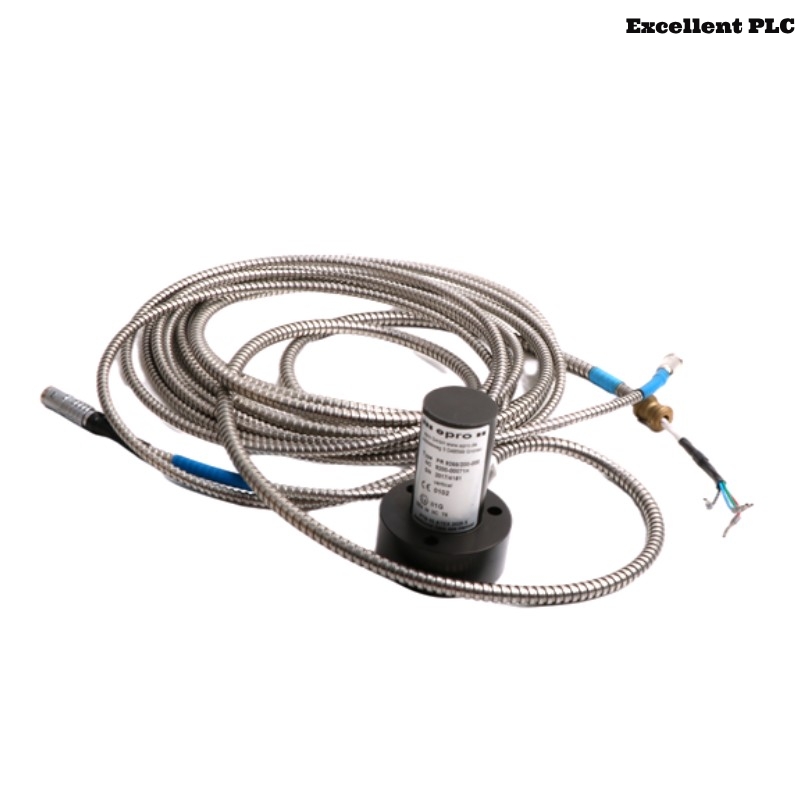

The Epro PR9268/202-100 Electrodynamic Velocity Sensor is a state-of-the-art sensor designed for precise vibration measurement and monitoring of rotating machinery. This electrodynamic velocity sensor is known for its high performance in both detecting and quantifying mechanical vibrations with remarkable accuracy, making it a preferred choice for predictive maintenance and condition monitoring applications.

Built by Epro, a leading provider of industrial monitoring solutions, the PR9268/202-100 offers reliable and long-lasting performance even in harsh industrial environments. It operates passively, meaning it requires no external power supply to function. This makes the sensor highly dependable, minimizing the risks of downtime due to power failures. The sensor is designed to detect vibration velocity, providing important insights into machinery health, such as alignment issues, imbalance, and wear.

This sensor is widely used across industries such as power generation, petrochemicals, mining, and water treatment, where the early detection of faults is crucial for operational safety and cost-efficiency. The Epro PR9268/202-100 is engineered to meet the highest standards of durability and precision, making it a valuable tool for both permanent installations and portable vibration monitoring.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | PR9268/202-100 |

| Measurement Type | Electrodynamic velocity sensing |

| Measuring Range | ±50 mm/s |

| Frequency Range | 10 Hz to 1,000 Hz |

| Sensitivity | 28.5 mV/mm/s ±5% |

| Output Signal | Voltage (passive sensor, self-generating) |

| Mounting Type | Threaded hole M8 or magnetic base |

| Housing Material | Stainless Steel |

| Operating Temperature Range | -25°C to +120°C |

| Shock Resistance | 1,000 g peak |

| Protection Rating | IP65 |

| Connector Type | MIL-C-5015 or custom cable |

| Cable Length | 1 to 10 meters (customizable) |

| Dimensions | 78 × 58 mm |

| Weight | 0.93 kg |

| Compliance | ISO 10816, DIN ISO 7919 |

Applications

The Epro PR9268/202-100 Electrodynamic Velocity Sensor is designed for a wide range of applications in industrial machinery monitoring. Below are some typical use cases:

-

Power Generation – Vibration monitoring of turbines, generators, and motors for fault detection.

-

Petrochemical and Chemical Industries – Monitoring large compressors, pumps, and motors to prevent mechanical failure.

-

Mining – Continuous vibration measurement of crushers, conveyors, and mills.

-

Water and Wastewater Treatment – Vibration analysis of pumps, blowers, and other mechanical systems.

-

Oil and Gas – Offshore and onshore machinery monitoring, particularly in critical equipment like compressors and gas turbines.

-

Manufacturing – Preventive maintenance for motors, fans, and other rotating machinery used in production lines.

The PR9268/202-100 provides essential data that helps operators and engineers to identify early signs of wear, imbalance, or misalignment, thus improving reliability and reducing unplanned downtime.

Product Advantages

-

Passive Operation – Does not require external power supply, enhancing reliability and simplifying the system.

-

High Sensitivity – Accurate velocity measurement with a sensitivity of 28.5 mV/mm/s, ensuring reliable data capture.

-

Wide Frequency Response – Effectively measures vibrations in machinery operating at different speeds (10 Hz to 1,000 Hz).

-

Robust Design – Stainless steel housing ensures the sensor can withstand harsh industrial environments.

-

Flexible Mounting Options – Can be easily mounted using an M8 threaded hole or a magnetic base, making installation simple and adaptable.

-

Long Operating Life – Designed for durability, capable of withstanding high shock loads (1,000 g peak) and extreme temperatures (-25°C to +120°C).

-

IP65 Protection Rating – Fully protected against dust and water jets, making it suitable for both indoor and outdoor environments.

-

Standardized Output – Compatible with a variety of industrial monitoring systems, making it easy to integrate into existing setups.

-

Cost-Effective – Reduces the need for frequent maintenance or replacements due to its durable, low-maintenance design.

-

Trusted Brand – Manufactured by Epro, a recognized leader in condition monitoring systems, ensuring high quality and reliable performance.

Frequently Asked Questions (FAQ)

-

What is the main purpose of the PR9268/202-100 sensor?

It is designed to measure the vibration velocity of rotating machinery, helping to identify potential faults and ensure operational reliability. -

How does the PR9268/202-100 sensor work?

It operates passively, generating a voltage proportional to the velocity of the vibrating surface to which it is attached. -

Is the sensor suitable for high-temperature environments?

Yes, it can operate in temperatures ranging from -25°C to +120°C, making it suitable for a wide range of industrial applications. -

Can the sensor be used for both low and high-speed machinery?

Yes, the wide frequency range of 10 Hz to 1,000 Hz allows it to measure both low-speed and high-speed machinery vibrations. -

Does the sensor require any external power supply?

No, it is a passive sensor and does not require external power, simplifying installation and reducing the risk of power-related failures. -

What is the output of the sensor?

The sensor outputs a voltage signal that is proportional to the vibration velocity of the equipment. -

What kind of mounting options does the PR9268/202-100 offer?

It can be mounted using an M8 threaded hole or a magnetic base for flexible installation. -

What is the protection rating of the sensor?

The sensor has an IP65 rating, meaning it is fully protected against dust and water jets. -

Can the sensor be used for temporary monitoring setups?

Yes, the magnetic base option makes it ideal for temporary setups where permanent mounting is not required. -

How durable is the PR9268/202-100 sensor?

It is built to withstand harsh conditions, with shock resistance of up to 1,000 g and a long operational lifespan under challenging environments.

Related Models (Same Series or Similar Functionality)

| Model | Measurement Type | Frequency Range | Sensitivity | Mounting Type |

|---|---|---|---|---|

| PR9268/200-100 | Electrodynamic Velocity | 10 Hz – 1 kHz | 28.5 mV/mm/s | M8 thread |

| PR9268/202-110 | Electrodynamic Velocity | 5 Hz – 1 kHz | 30 mV/mm/s | Magnetic base |

| PR9268/203-100 | Electrodynamic Velocity | 10 Hz – 1.5 kHz | 28 mV/mm/s | Flange mount |

| PR9268/205-100 | Electrodynamic Velocity | 10 Hz – 800 Hz | 25 mV/mm/s | Adhesive mount |

| PR9268/206-100 | Electrodynamic Velocity | 10 Hz – 1 kHz | 28.5 mV/mm/s | M8 thread |

| PR9268/208-100 | Electrodynamic Velocity | 5 Hz – 1.2 kHz | 30 mV/mm/s | Side exit cable |

Popular Models from the Same Brand (Epro)

| Model | Product Type | Key Function | Application Area |

|---|---|---|---|

| PR6423/002-030 | Eddy Current Sensor | Shaft displacement measurement | Turbines, compressors |

| MMS3120/022-100 | Vibration Monitoring Module | Multi-channel vibration data acquisition | Industrial monitoring systems |

| PR6424/014-040+CON021 | Eddy Current Probe System | Axial and radial displacement | Rotating machinery |

| MMS6110 | Diagnostic Interface Module | Signal processing for sensors | Online monitoring systems |

| CON011 | Connection Module | Sensor signal interface | Vibration monitoring systems |

| PR6423/003-010 | Eddy Current Sensor | Shaft vibration measurement | Petrochemical, power plants |

Excellent PLC

Excellent PLC