| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

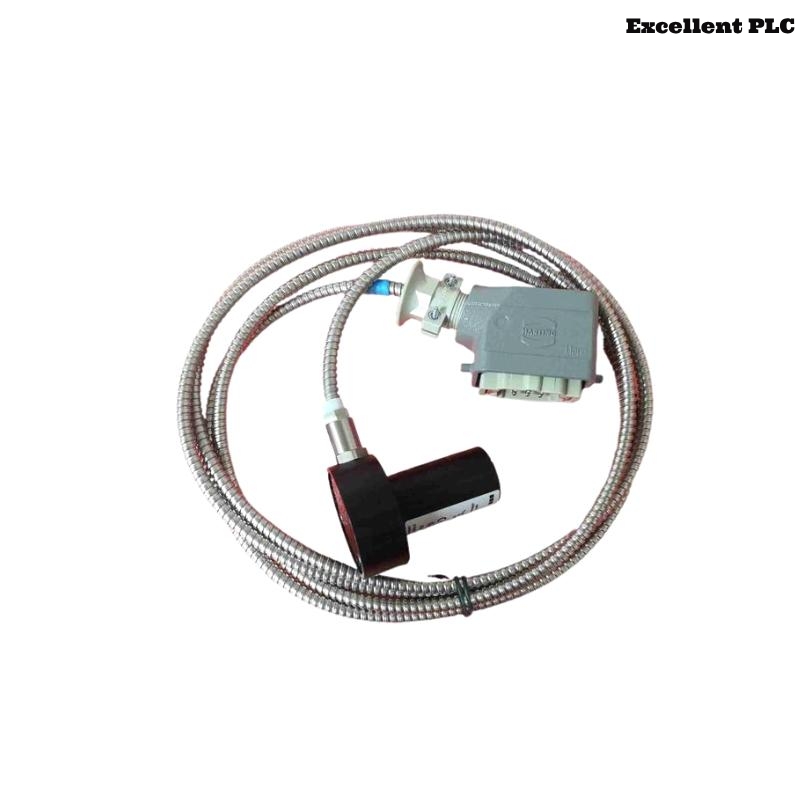

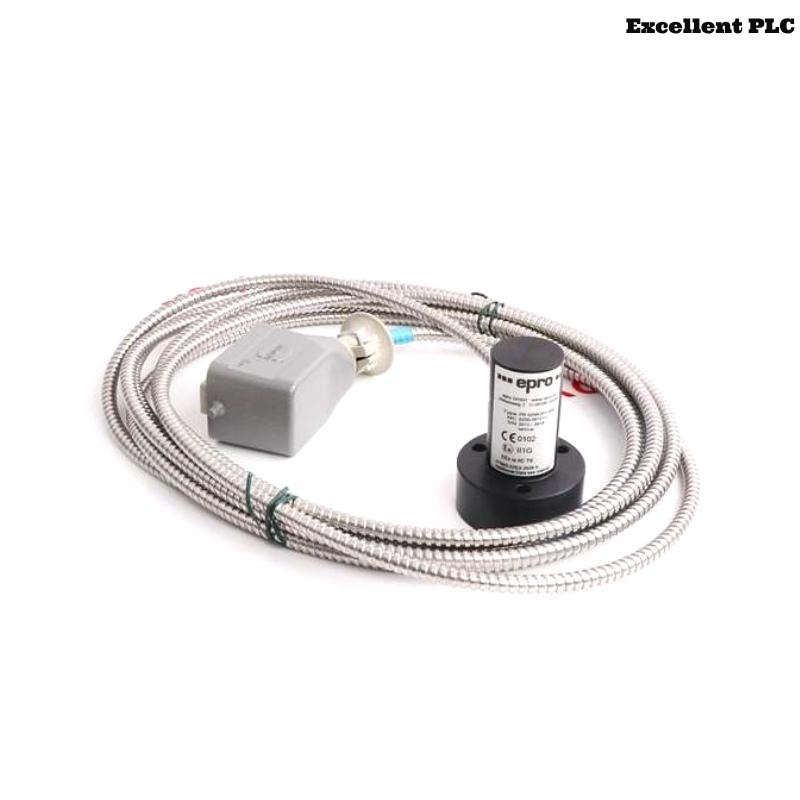

The Epro PR9268/303-000 is an industrial-grade electrodynamic velocity sensor developed for accurate and reliable measurement of mechanical vibration in rotating machinery. Designed and manufactured by Epro, a trusted Emerson brand, the PR9268/303-000 is part of the proven PR9268 series, widely used in machinery protection and condition monitoring systems.

The sensor converts mechanical vibrations into electrical signals using a robust coil-magnet assembly. This passive operating principle ensures no external power supply is required, making it especially well-suited for rugged industrial environments with harsh conditions such as high temperatures, vibrations, and contamination.

Engineered for horizontal mounting, the PR9268/303-000 is optimized for long-term reliability and ease of integration into existing plant monitoring infrastructure.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | PR9268/303-000 |

| Sensor Type | Electrodynamic velocity sensor |

| Operating Principle | Coil and magnet system (self-generating) |

| Output Signal | Analog voltage (AC), proportional to vibration velocity |

| Sensitivity | 28.5 mV/mm/s ±5% |

| Frequency Range | 10 Hz – 1,000 Hz (-3 dB) |

| Measuring Range | 0 – 50 mm/s RMS |

| Natural Frequency | ~10 Hz |

| Mounting Orientation | Horizontal |

| Mounting Thread | M8 x 1.25 or M10 x 1.5 |

| Housing Material | Stainless steel (corrosion-resistant) |

| Connector Type | MIL-C-5015 2-pin connector or integral cable |

| Shock Resistance | Up to 500 g |

| Ingress Protection | IP65 / IP67 (depending on variant) |

| Operating Temperature | -30°C to +120°C |

| Storage Temperature | -40°C to +130°C |

| Weight | 0.93 kg |

| Dimensions | 78 × 58 mm |

| Certifications | CE, RoHS; optional ATEX-certified versions for hazardous areas |

Applications

The PR9268/303-000 is designed for a wide range of vibration monitoring applications, especially in critical rotating equipment where early fault detection can prevent costly breakdowns:

-

Steam and Gas Turbines

-

Centrifugal and Reciprocating Compressors

-

Industrial Fans and Blowers

-

Pumps and Motors in Oil & Gas Facilities

-

Gearboxes in Manufacturing Lines

-

Paper Machines and Calendar Rolls

-

Steel Mill Equipment

-

Mining and Cement Plant Machinery

It is commonly used in both portable diagnostic systems and permanently installed online monitoring systems, integrated with vibration monitors, DCS, and condition-based maintenance platforms.

Product Advantages

-

Passive Design – No Power Required:

Generates its signal through internal motion, eliminating the need for external power and simplifying integration. -

High Mechanical Robustness:

Stainless steel construction and IP-rated sealing ensure resistance to industrial contaminants, temperature changes, and mechanical shocks. -

Excellent Signal Consistency:

Delivers stable and accurate readings over years of continuous use, even in vibrating environments. -

Industry-Standard Sensitivity:

With 28.5 mV/mm/s output, it is fully compatible with most vibration monitors and analyzers. -

Flexible Mounting:

Supports various thread sizes and accessories such as magnetic bases for temporary or permanent mounting. -

Low Cost of Ownership:

Durable design minimizes replacement cycles, while passive operation reduces energy and maintenance costs. -

Global Compliance:

CE and RoHS certified; optional ATEX certification makes it suitable for hazardous area use in petrochemical plants and refineries.

Frequently Asked Questions (FAQ)

-

What is the function of the PR9268/303-000 sensor?

It measures the vibration velocity of rotating machinery to detect mechanical faults. -

Is the PR9268/303-000 suitable for permanent installation?

Yes, it is designed for long-term operation in both permanent and temporary installations. -

Does the sensor require an external power supply?

No, it is a self-generating sensor and does not require external power. -

Can this sensor be used in hazardous zones?

Yes, ATEX-certified variants are available for use in hazardous areas. -

What monitoring equipment is compatible with this sensor?

Any monitoring device that accepts AC voltage input for vibration velocity is compatible. -

Is the sensor weatherproof?

Yes, its IP65/IP67 rating ensures protection against dust and water ingress. -

Can it be used in vertical mounting?

No, this specific model is optimized for horizontal mounting. Use a vertical model for vertical surfaces. -

What is the lifespan of the sensor under normal conditions?

Typically over 10 years in standard industrial environments. -

How is it connected to a monitoring system?

Via a MIL-style connector or a permanently attached cable, depending on the variant. -

Is it compatible with Emerson or other third-party monitoring systems?

Yes, it is fully compatible with Emerson systems and most third-party monitoring solutions.

Recommended Related Models (Same Series / Function)

| Model Number | Description | Mounting |

|---|---|---|

| PR9268/302-100 | Standard horizontal electrodynamic sensor | Horizontal |

| PR9268/203-100 | Vertical-mount sensor | Vertical |

| PR9268/304-000 | Explosion-proof housing version | Horizontal/Vertical |

| PR9268/205-100 | Compact size for limited spaces | Horizontal |

| PR9268/211-100 | Reinforced sensor for high shock environments | Horizontal |

| PR9268/206-100 | Wide-frequency response sensor | Horizontal |

Popular Epro Models (Same Brand – Emerson)

| Model Number | Description | Function |

|---|---|---|

| PR6423/002-030 | Eddy current proximity probe | Shaft displacement |

| PR6424/010-140 | High-temperature eddy current sensor | Turbine monitoring |

| CON011 | Signal converter for eddy current sensors | Signal conditioning |

| MMS3120/022-100 | Dual-channel vibration monitor | Machinery protection |

| MMS6120 | Compact monitor for rotating equipment | Online monitoring |

| TQ402 | Keyphasor module for speed/phase measurement | Rotational speed sensing |

Excellent PLC

Excellent PLC