| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

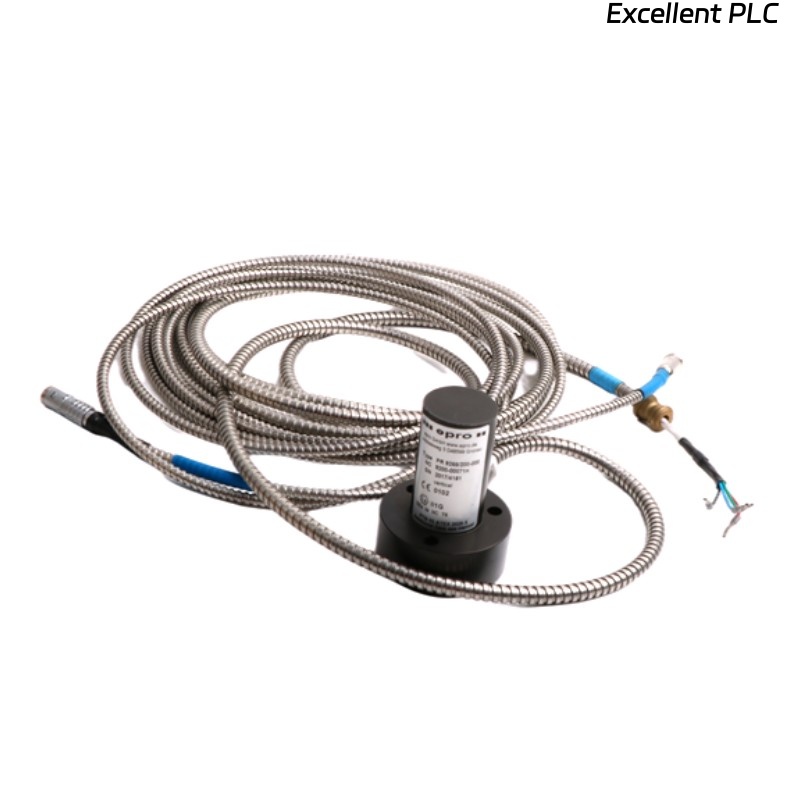

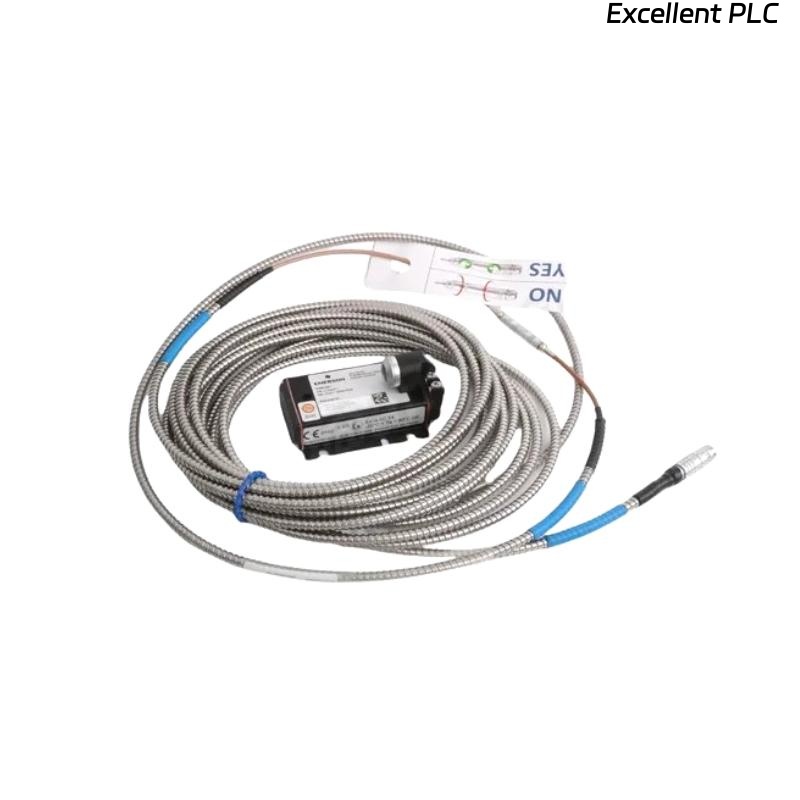

The Epro PR9376/20 is an industrial-grade, non-contact eddy current sensor specifically designed for monitoring the rotational speed and position of metallic targets in critical rotating equipment. Manufactured by EPRO, a trusted name in condition monitoring and part of Emerson’s product portfolio, this sensor stands out for its robust performance in aggressive industrial environments such as turbine housings, gearboxes, and centrifugal compressors.

The PR9376/20 sensor is capable of detecting both speed and proximity by identifying the movement of ferromagnetic materials (e.g., gear teeth or shaft notches). It is widely used in conjunction with EPRO CON-series signal converters to provide real-time monitoring data for predictive maintenance and protection systems.

Engineered for durability, precision, and stability, the PR9376/20 is suitable for applications requiring reliable operation under high temperature, vibration, and electromagnetic interference.

Product Specifications

| Parameter | Description |

|---|---|

| Model | PR9376/20 |

| Type | Speed/Proximity Sensor |

| Sensing Principle | Eddy Current (Inductive, Non-contact) |

| Application | Speed & Proximity Measurement |

| Target Material | Ferromagnetic materials (steel, iron, etc.) |

| Measuring Range | 0.5 mm to 2.2 mm typical |

| Operating Frequency | 0 Hz – 20,000 Hz |

| Output Signal | Requires converter (CON011/CON021), analog/frequency output |

| Supply Voltage | Provided via converter unit |

| Operating Temperature Range | -35°C to +120°C |

| Storage Temperature | -40°C to +130°C |

| Environmental Protection | IP67 (dustproof, water-resistant) |

| Vibration Resistance | 20 g (10–2000 Hz) |

| Housing Material | Stainless Steel |

| Thread Size | M14 x 1.5 |

| Mounting | Threaded Mounting |

| Cable Type | Shielded, PTFE-insulated |

| Cable Length | Standard 5 m (custom lengths available) |

| Diameter | 14 mm |

| Weight | 0.21 kg |

| Certifications | CE, RoHS |

Product Applications

-

Turbine Overspeed Monitoring

Designed to track shaft speed precisely for steam, gas, and hydro turbines, enabling rapid shutdowns if speed exceeds safe limits. -

Gear Tooth Sensing

Installed adjacent to rotating gears, the sensor detects passing teeth to calculate RPM and proximity. -

Compressor and Pump Speed Feedback

Offers reliable performance in high-vibration and high-temperature zones typically found in oil & gas or chemical plant environments. -

Rotating Equipment Diagnostics

Part of a broader condition monitoring system, providing input data for bearing health and shaft behavior analysis. -

Industrial Safety Systems

Integrated into automated protection logic for rotating machinery, enabling safe and controlled stops.

Product Advantages

-

Non-contact Technology

Eliminates physical wear and ensures long-lasting operation, even in high-speed systems. -

High-Temperature Resilience

Capable of functioning continuously at up to 120°C with high accuracy and stability. -

Strong Mechanical Build

Machined stainless steel body and hermetically sealed design ensure resistance to physical and chemical stressors. -

Electromagnetic Immunity

Designed to operate in electrically noisy environments without signal degradation. -

Flexible Integration

Pairs seamlessly with EPRO’s signal converters and monitoring systems, simplifying system architecture. -

Low Maintenance

Minimal calibration needs, long MTBF, and solid-state design make it ideal for remote or inaccessible installations. -

IP67 Rating

Fully protected against ingress from dust and water, ideal for outdoor or process environments. -

Customizable Cable Lengths

Factory options for 5, 10, or longer meter cables reduce need for splicing in long conduit runs.

Frequently Asked Questions (FAQ)

-

What does the Epro PR9376/20 sensor detect?

It detects both rotational speed and proximity of ferromagnetic targets like gears and shafts. -

Can I connect this sensor directly to a PLC?

No, it must be connected through a compatible signal converter like CON011 or CON021. -

Is the sensor safe to use in explosive environments?

While robust, certification for hazardous locations depends on the complete system setup. -

How do I mount the PR9376/20?

It is designed for threaded mounting using its M14 x 1.5 body thread. -

What type of cable does it come with?

It features a shielded, PTFE-insulated cable ideal for industrial applications. -

What is the maximum measurable speed?

The sensor supports frequency detection up to 20,000 Hz, which translates to high-speed RPM monitoring depending on the target geometry. -

Is this sensor suitable for low-temperature environments?

Yes, it operates down to -35°C and can be stored at -40°C. -

Can I use this sensor for displacement measurements?

It is optimized for speed and proximity, not for precision displacement applications. -

What materials can it detect?

It detects only conductive, ferromagnetic materials such as steel. -

What is the weight of the sensor?

0.21 kg.

Related Models from the Same Series

| Model | Description | Measurement | Thread Size | Cable Length |

|---|---|---|---|---|

| PR9376/10 | General-purpose speed/proximity sensor | Speed & Proximity | M14 x 1.5 | 5 m |

| PR9376/11 | Shorter version with reduced body length | Speed & Proximity | M12 x 1.0 | 3 m |

| PR9376/30 | Wide-gap sensor for coarse tooth counting | Speed only | M18 x 1.5 | 10 m |

| PR9376/50 | High-temperature version | Speed & Proximity | M14 x 1.5 | 5 m |

| PR9376/70 | Extended frequency range model | Speed detection | M16 x 1.5 | 10 m |

| PR9376/21 | Variant with pre-wired connector | Speed & Proximity | M14 x 1.5 | 5 m (plugged) |

Popular Models from the Same Brand (EPRO)

| Model | Description | Function | Sensor Type | Typical Application |

|---|---|---|---|---|

| PR6423/002-030 | Eddy current sensor for radial vibration | Vibration & Displacement | Proximity Sensor | Turbomachinery |

| PR6424/014-040 | Sensor with CON021 for shaft monitoring | Displacement | Proximity Probe + Module | Compressor/bearing monitoring |

| MMS3110 | Monitoring module for vibration/speed signals | Signal Conditioning | Monitoring Module | Condition monitoring systems |

| MMS6120 | Overspeed trip amplifier for turbines | Overspeed Protection | Control Module | Rotating equipment safety |

| CON011 | Basic signal converter for PR9376/PR6423 series | Signal Conversion | Electronic Converter | Sensor signal processing |

| CON021 | Advanced signal converter with diagnostics | Signal Conditioning | Electronic Converter | High-precision installations |

Excellent PLC

Excellent PLC