| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

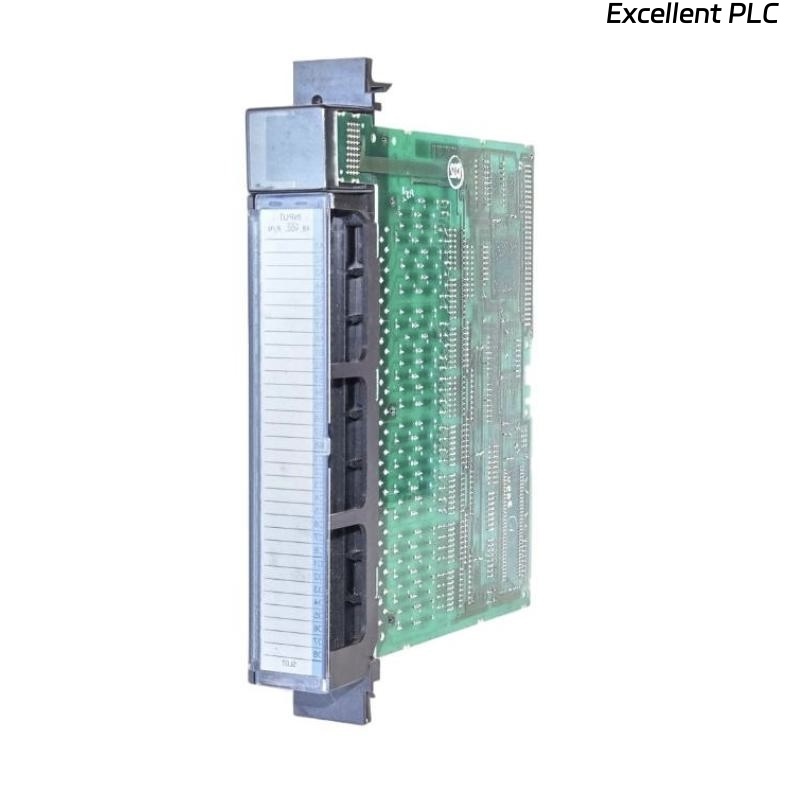

The GE Fanuc IC693MDR390 is a Relay I/O Module designed for use in the Series 90-30 PLC system. This module offers 16 relay inputs and 16 relay outputs, providing reliable and versatile I/O functionality for a variety of industrial automation applications. The module is designed to integrate seamlessly into the GE Fanuc PLC architecture, offering flexibility in controlling and monitoring field devices such as sensors, actuators, and relays in industrial environments.

The IC693MDR390 module utilizes dry contact relays for input and output signals, making it suitable for interfacing with a broad range of external devices, including motor controllers, alarms, and switches. It also features optical isolation between the PLC and external devices, providing protection against electrical surges and noise that are common in industrial settings. The module is easy to install and configure, making it a valuable addition to any GE Fanuc-based control system.

Key Features

-

16 Relay Inputs: Supports 16 digital input points that can be used for monitoring external devices, such as sensors, limit switches, or alarm conditions.

-

16 Relay Outputs: Provides 16 relay outputs to control external devices, such as motors, actuators, and relays.

-

Dry Contact I/O: Utilizes dry contact relay inputs and outputs, suitable for switching both AC and DC loads.

-

Optical Isolation: Features optical isolation between the relay contacts and the PLC, ensuring protection against electrical noise and voltage spikes.

-

Compact and Modular: Easily integrates into a GE Fanuc Series 90-30 PLC system, requiring minimal space and reducing installation complexity.

-

Real-Time Diagnostics: Equipped with diagnostic LEDs for real-time monitoring of input and output statuses, allowing for quick identification and troubleshooting of issues.

-

High Current Rating: The relay outputs are capable of handling up to 5A at 240 VAC or 5A at 30 VDC, offering high switching capacity for various industrial applications.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | IC693MDR390 |

| Product Type | Relay I/O Module |

| Relay Inputs | 16 Digital Inputs (Dry Contact) |

| Relay Outputs | 16 Digital Outputs (Dry Contact) |

| Relay Output Rating | 5 A at 240 VAC / 5 A at 30 VDC |

| Input Voltage | 5 to 240 VAC/DC (AC/DC loads) |

| Backplane Current Draw | 200 mA maximum |

| Relay Isolation | Optical Isolation between relay contacts and PLC |

| LED Indicators | 16 individual status LEDs for input/output monitoring |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C (-40°F to 185°F) |

| Dimensions | 122 × 82 × 60 mm |

| Weight | 1.36 kg |

| Wiring Method | Screw terminal block |

| Response Time | <10 ms |

| Protection | Overcurrent and short-circuit protection for each relay |

Industry Applications

The GE Fanuc IC693MDR390 Relay I/O Module is widely used in industrial automation systems across various industries. Key applications include:

-

Manufacturing Automation: Ideal for monitoring and controlling sensors, actuators, and relays in production lines.

-

Energy Management: Controls relays in electrical power distribution and generation systems.

-

Water Treatment: Monitors sensors and controls pumps and valves in water treatment plants.

-

Building Automation: Interfaces with HVAC, lighting systems, and security equipment in commercial and industrial buildings.

-

Oil & Gas: Provides reliable control for pumps, valves, and safety equipment in oil and gas extraction operations.

-

Transportation Systems: Controls traffic signals, gates, and other field devices in transportation and logistics applications.

Product Advantages

-

Flexible Input and Output Control: With 16 relay inputs and 16 relay outputs, the IC693MDR390 provides extensive control capabilities, ideal for complex industrial processes.

-

Optical Isolation for Protection: The optical isolation feature protects the PLC system from external electrical disturbances, ensuring the longevity and reliability of the control system.

-

High Switching Capacity: The module supports up to 5A of switching current at both 240 VAC and 30 VDC, handling a wide range of field devices.

-

Compact Design: The compact design makes the module easy to install in limited spaces within a GE Fanuc Series 90-30 PLC system.

-

Real-Time Diagnostics: LED indicators for each relay input and output help monitor operational status and diagnose issues, improving troubleshooting efficiency.

-

Broad Range of Applications: Suitable for a wide array of industries including manufacturing, building automation, energy, water treatment, and more.

Frequently Asked Questions (FAQ)

-

Q: How many inputs and outputs does the IC693MDR390 module have?

A: The module provides 16 relay inputs and 16 relay outputs. -

Q: Can the module handle both AC and DC loads?

A: Yes, the relay outputs can handle both AC and DC loads. -

Q: What is the maximum current rating for the relay outputs?

A: The relay outputs are rated for 5 A at 240 VAC or 5 A at 30 VDC. -

Q: What type of protection does the module offer?

A: The module provides overcurrent and short-circuit protection for each relay output. -

Q: How is the IC693MDR390 module wired?

A: The module uses screw terminal blocks for wiring, making installation easy and secure. -

Q: What is the response time of the relay inputs and outputs?

A: The response time is less than 10 ms for both input and output signals. -

Q: What is the operating temperature range for this module?

A: The module operates in temperatures ranging from 0°C to 60°C (32°F to 140°F). -

Q: Can this module be used in hazardous environments?

A: While the module is robust and designed for industrial environments, it should be assessed for specific environmental hazards. It is rated for general industrial use. -

Q: How do the LEDs on the module help with diagnostics?

A: Each relay input and output has an associated LED indicator to show its status, helping with quick identification of faults. -

Q: Is the IC693MDR390 module compatible with all GE Fanuc PLCs?

A: Yes, the IC693MDR390 is designed to work seamlessly with GE Fanuc Series 90-30 PLC systems.

Related or Similar GE Fanuc Modules

| Model Number | Description |

|---|---|

| IC693MDL931 | 16-Point Relay Output Module |

| IC693MDL930 | 32-Point Relay Output Module |

| IC693MDL931 | 16-Point Relay Output Module |

| IC693MDL942 | 8-Point Relay Output Module |

| IC693MDL935 | 8-Point Digital Output Module |

| IC693MDL960 | 32-Point Relay Input Module |

Popular GE Fanuc Modules (Same Brand)

| Model Number | Description |

|---|---|

| IC693CPU374 | High-Performance CPU for Series 90-30 PLCs |

| IC693PWR330 | Power Supply Module |

| IC693BEM331 | Ethernet Communications Module |

| IC693ALG391 | Analog Current Input Module |

| IC693MDL645 | 16-Point AC Output Module |

| IC693ACC302 | Memory Backup Battery |

Excellent PLC

Excellent PLC