| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

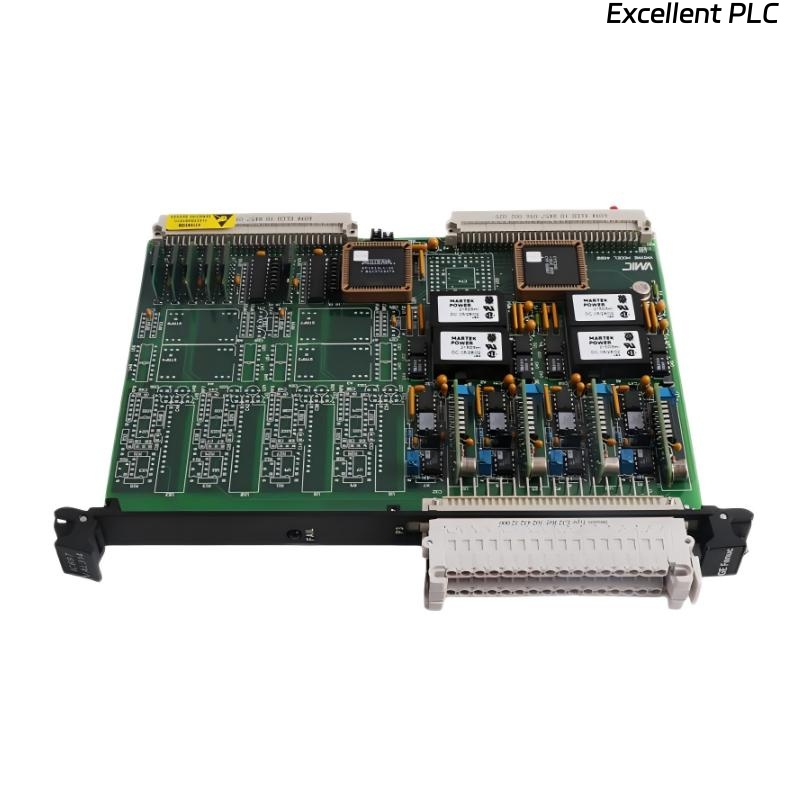

The GE Fanuc IS215UCVEM06A is a high-performance VME-based Controller Module used in GE Mark VI and Mark VIe turbine control systems, serving as a central processing unit (CPU) responsible for executing control logic, managing communication between system components, and supporting critical system diagnostics and operation.

As a variant of the UCVE series (Universal Control VME Embedded) modules, the IS215UCVEM06A integrates advanced processor architecture, dual Ethernet ports, and serial communication interfaces, along with onboard volatile and non-volatile memory. It supports real-time operating systems such as QNX or VxWorks, ensuring deterministic behavior and robust control performance in mission-critical environments.

This controller is widely deployed in gas turbines, steam turbines, and balance-of-plant applications, where reliability, precision, and availability are crucial.

Key Features

-

Embedded real-time control processor for turbine and process control

-

Dual 10/100Base-T Ethernet ports for redundant or segmented networks

-

2 × RS-232 serial ports for diagnostics or legacy device communication

-

Supports GE ToolboxST software for configuration and monitoring

-

VMEbus master/slave interface for high-speed I/O communication

-

Industrial-grade memory: flash and DRAM for fast execution and data logging

-

Compatible with GE Mark VI/Mark VIe systems

-

Status LEDs for diagnostics and activity monitoring

-

Non-hot-swappable – replaceable only with system shutdown

-

Ruggedized for industrial and power generation environments

Technical Specifications

| Specification | Details |

|---|---|

| Product Type | VME Embedded Controller Module |

| Model Number | IS215UCVEM06A |

| System Compatibility | GE Mark VI / Mark VIe |

| CPU Type | Embedded processor (Intel-based, architecture varies by revision) |

| Memory | Onboard DRAM and flash memory (sizes depend on configuration) |

| Ethernet Ports | 2 × 10/100 Mbps (RJ-45 connectors) |

| Serial Ports | 2 × RS-232 (DB9 connectors) |

| Operating System | QNX RTOS or VxWorks |

| VME Interface | VME master/slave bus interface |

| LED Indicators | Power, Status, Ethernet Activity, Module Health |

| Power Supply | Supplied from VME rack backplane |

| Firmware Upgrade | Supported via Ethernet |

| Configuration Software | GE ToolboxST, ControlST |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Dimensions | 159 x 178mm |

| Weight | 0.907 kg |

| Certifications | UL, CE, CSA, RoHS |

Industry Applications

The IS215UCVEM06A module is an integral component in advanced turbine and plant automation platforms across multiple industries, including:

-

Gas and Steam Turbines – Core CPU for turbine logic, sequencing, and protection

-

Power Generation – Control of auxiliary systems in thermal, hydro, and nuclear power plants

-

Oil & Gas – Compressor station control and pipeline automation

-

Petrochemical Plants – Boiler control, heater sequencing, and rotating equipment logic

-

Water & Wastewater Treatment – Distributed process control and sequencing

-

Industrial Manufacturing – Real-time process management in large-scale DCS systems

Product Advantages

-

Purpose-built for GE turbine systems, ensuring seamless hardware/software integration

-

Dual Ethernet enhances network reliability and allows IONet segmentation

-

Real-time operating system ensures deterministic execution of control logic

-

Compatible with GE’s software ecosystem (ToolboxST, ControlST) for intuitive control

-

Supports long-term system availability with firmware upgrade and diagnostics

-

Hardware status LEDs simplify troubleshooting

-

VME architecture offers reliable and scalable I/O connectivity

-

Proven field reliability across decades of turbine and industrial control deployments

Frequently Asked Questions (FAQ)

1. What system uses the IS215UCVEM06A?

It is used in GE Mark VI and Mark VIe turbine control systems as the main control processor.

2. What communication interfaces are available?

The module includes two Ethernet ports and two RS-232 serial ports.

3. Can this module be hot-swapped?

No. It is not hot-swappable and must be replaced with the system powered down.

4. What operating system does it use?

It runs a real-time operating system, typically QNX or VxWorks, for deterministic control.

5. How is the module configured?

Using GE ToolboxST or ControlST software via Ethernet.

6. Is it firmware upgradeable?

Yes. Firmware can be upgraded via Ethernet using the appropriate GE tools.

7. What type of memory does it use?

The module includes DRAM for runtime processing and flash for firmware and storage.

8. Can I use this in other VME systems?

No, it is designed specifically for GE control architectures, especially Mark VI/VIe.

9. What does “M06A” indicate in the part number?

It denotes the hardware version and firmware configuration, typically aligning with specific system versions.

10. What happens if this module fails?

The system will trigger a diagnostic alarm, and a replacement module must be installed with a full power cycle.

Related GE Mark VI/VIe Modules

| Model | Description |

|---|---|

| IS215UCVEH2A | UCVE Controller Module with earlier revision |

| IS215VCMIH2C | VME Communication Interface Module |

| IS200TRLYH1BGG | Relay Output Terminal Board |

| IS200TREGH1B | Turbine Generator Protection Terminal Board |

| IS200VAICH1C | Analog Input Board (Vibration/Analog Signal Interface) |

| IS200STAIH2ACB | High-density Analog Input Terminal Board |

Popular GE Fanuc Industrial Products

| Model | Description |

|---|---|

| IC695CPU320 | RX3i 1 GHz CPU Module |

| IC695ETM001-EP | RX3i Ethernet Interface Module |

| IC694MDL940C | 32-Point Digital Output Module |

| IC695CHS012 | 12-Slot RX3i Backplane |

| IC695HSC304-DA | 4-Channel High-Speed Counter Module |

| IC695PSA140 | RX3i 120/240VAC Power Supply |

Excellent PLC

Excellent PLC