| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

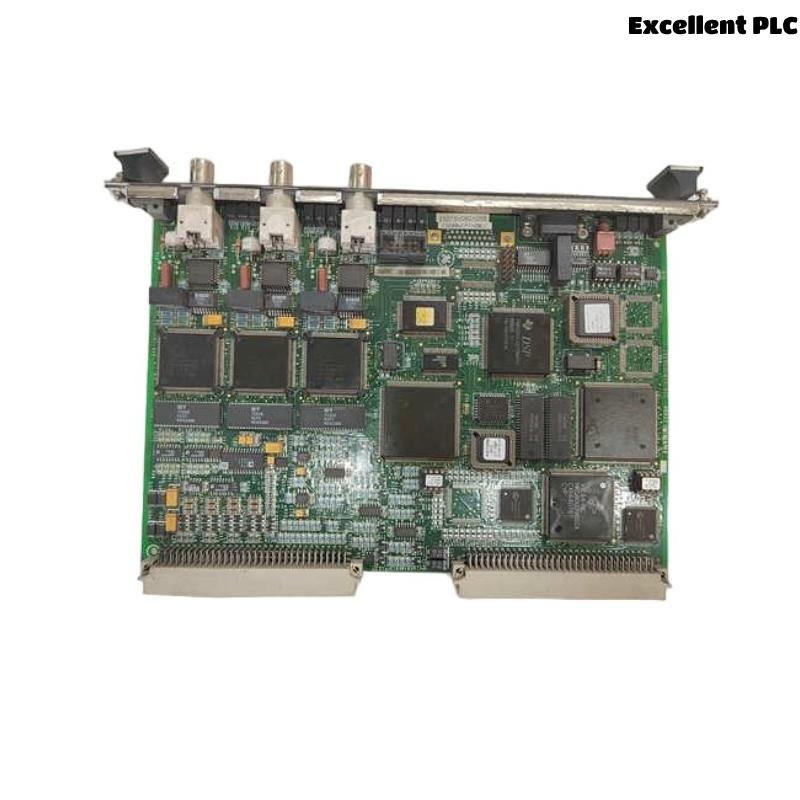

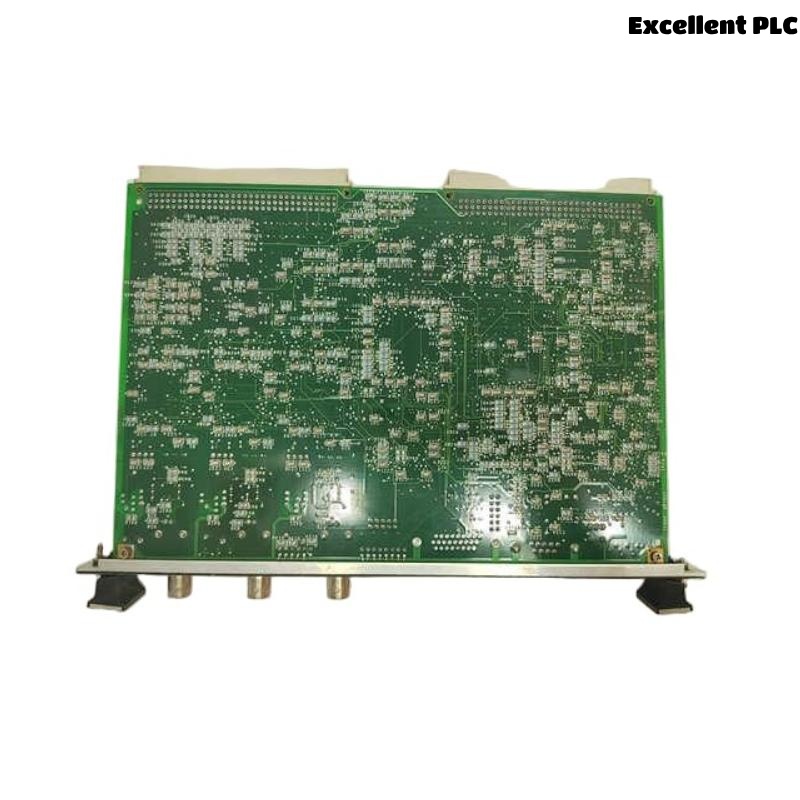

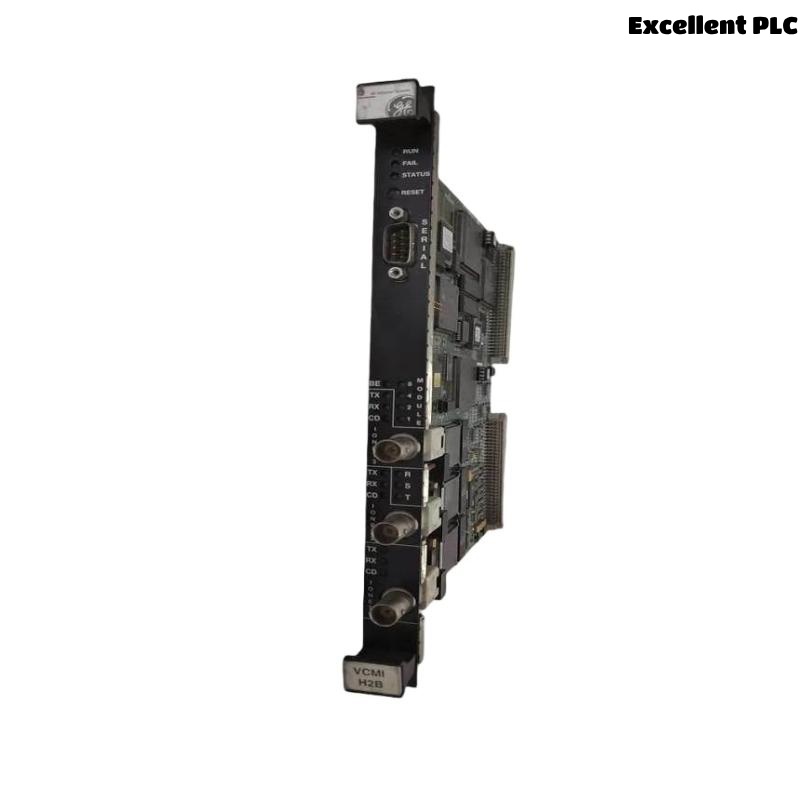

The GE Fanuc IS215VCMIH2BB is a VCMI (VME Communication Master Interface) board used as the primary bus controller in GE Mark VI and Mark VIe control systems. It functions as the master communication interface between the VME processor (such as UCVE modules) and the I/O boards within the turbine control system rack.

The VCMIH2BB board manages communication over the I/O network (IONet), supports peer-to-peer data transfer, and provides deterministic message passing between system components. This module is essential for achieving real-time control synchronization and robust system diagnostics in mission-critical applications like gas turbines, steam turbines, and balance-of-plant equipment.

Key Features

-

VMEbus Master Interface – Acts as the central communication bus controller

-

Enables real-time deterministic communication among turbine control modules

-

Supports IONet redundancy and high-speed data transfer

-

Facilitates communication between UCVE processors and I/O boards

-

Includes diagnostic LEDs for status and fault indication

-

Compatible with GE ToolboxST and ControlST software for configuration and monitoring

-

System-critical role in Mark VI / VIe architecture

-

Industrial-grade design for continuous operation in harsh environments

Technical Specifications

| Specification | Details |

|---|---|

| Product Type | VCMI Bus Master Communication Controller Board |

| Model Number | IS215VCMIH2BB |

| System Compatibility | GE Mark VI / Mark VIe |

| Bus Interface | VMEbus Master |

| Supported Networks | IONet, TMR communication |

| LED Indicators | Status, Fault, VME Activity, Network Communication |

| Communication Type | Peer-to-peer, broadcast, point-to-point |

| Redundancy Support | Yes, for IONet channels |

| Diagnostic Support | Yes, via ToolboxST or ControlST |

| Hot Swap | No |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95%, non-condensing |

| Dimensions | 266.7 x 20mm |

| Weight | 1.2 kg |

| Mounting Type | VME rack slot |

| Certifications | UL, CE, CSA, RoHS |

Industry Applications

The IS215VCMIH2BB plays a vital role in safety, monitoring, and process control in a variety of industries, including:

-

Gas Turbines – Synchronization of sensor and actuator signals

-

Steam Turbines – Timing-critical communication across I/O modules

-

Power Generation Plants – Integration of turbine, boiler, and generator subsystems

-

Petrochemical Plants – Control of complex rotating equipment systems

-

Oil & Gas Facilities – Compressor control, redundancy-enabled communication

-

Industrial Automation – Backbone of distributed I/O and control data exchange

Product Advantages

-

Centralized communication management for turbine systems

-

Real-time deterministic control over the VME and IONet communication backbones

-

Ensures system-wide synchronization and stability

-

Designed to support redundant control architectures

-

Offers enhanced diagnostic capabilities through software and onboard LEDs

-

Robust and reliable even in harsh operating environments

-

Seamless integration with GE’s ToolboxST/ControlST environment

-

Proven reliability in high-availability turbine control deployments

Frequently Asked Questions (FAQ)

1. What is the function of the IS215VCMIH2BB module?

It serves as the bus master communication controller, managing data flow across the VMEbus and coordinating communication between the UCVE processor and I/O boards.

2. Is this board used in Mark VI or Mark VIe systems?

Yes, it is compatible with both GE Mark VI and Mark VIe control systems.

3. Does this module support redundancy?

Yes. It supports IONet redundant communication, crucial for fault-tolerant systems.

4. How is the module configured?

It is configured using GE ToolboxST or ControlST software, which provides diagnostic and setup tools.

5. Can it be hot-swapped?

No, this module is not hot-swappable and must be replaced with the system powered down.

6. What happens if the VCMI board fails?

The system will log a diagnostic alarm, and control may be interrupted depending on system redundancy and configuration.

7. How does it interact with the UCVE processor?

The VCMI facilitates communication between the UCVE processor and other system I/O modules over the VMEbus and IONet.

8. Are there LED indicators for diagnostics?

Yes, the board features multiple LEDs that indicate power, communication activity, and faults.

9. Can this be used in simplex and TMR systems?

Yes, it is suitable for both simplex and Triple Modular Redundant (TMR) configurations.

10. Is this module still supported by GE?

Yes, it is still in active use and supported as part of GE Mark VI/VIe systems, though lifecycle status should be verified for specific projects.

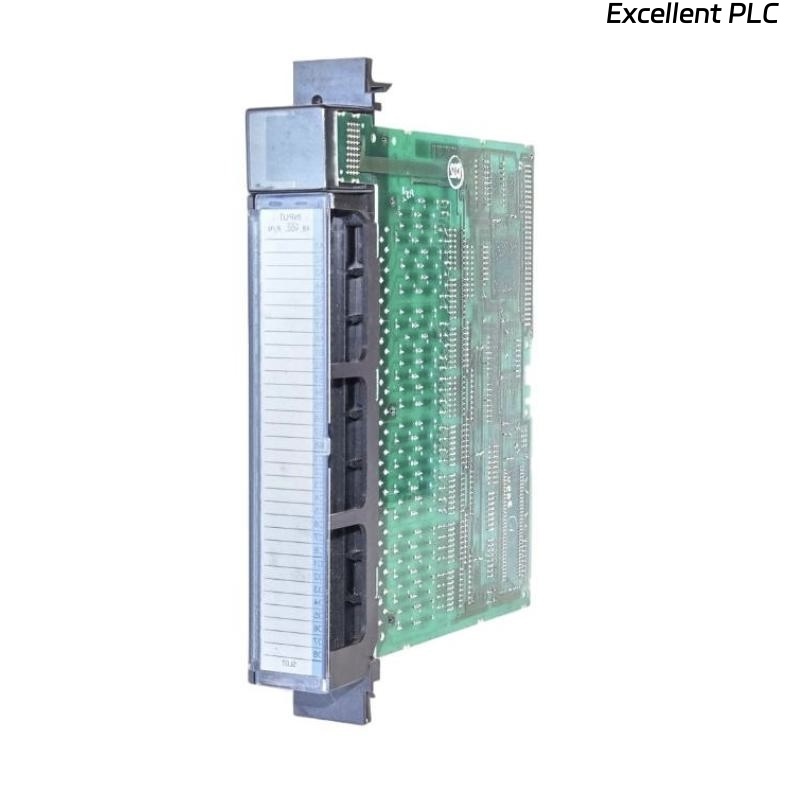

Related GE Mark VI / VIe Modules

| Model | Description |

|---|---|

| IS215UCVEH2A | VME Embedded UCVE Controller Module |

| IS215UCVEM06A | Enhanced UCVE Controller Module |

| IS200TRLYH1BGG | Relay Output Terminal Board |

| IS200STAIH2ACB | Analog Input Terminal Board |

| IS200TREGH1B | Generator Protection Terminal Board |

| IS215ACLIH1A | Analog Current Loop Interface Module |

Popular GE Fanuc Industrial Automation Modules

| Model | Description |

|---|---|

| IC695CPU320 | RX3i High-Speed CPU Module |

| IC695ETM001-EP | RX3i Ethernet Interface Module |

| IC694MDL940C | 32-Point Digital Output Module |

| IC695CHS012 | 12-Slot RX3i Backplane |

| IC695HSC304-DA | 4-Channel High-Speed Counter Module |

| IC695PSA140 | RX3i 120/240VAC Power Supply |

Excellent PLC

Excellent PLC