| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

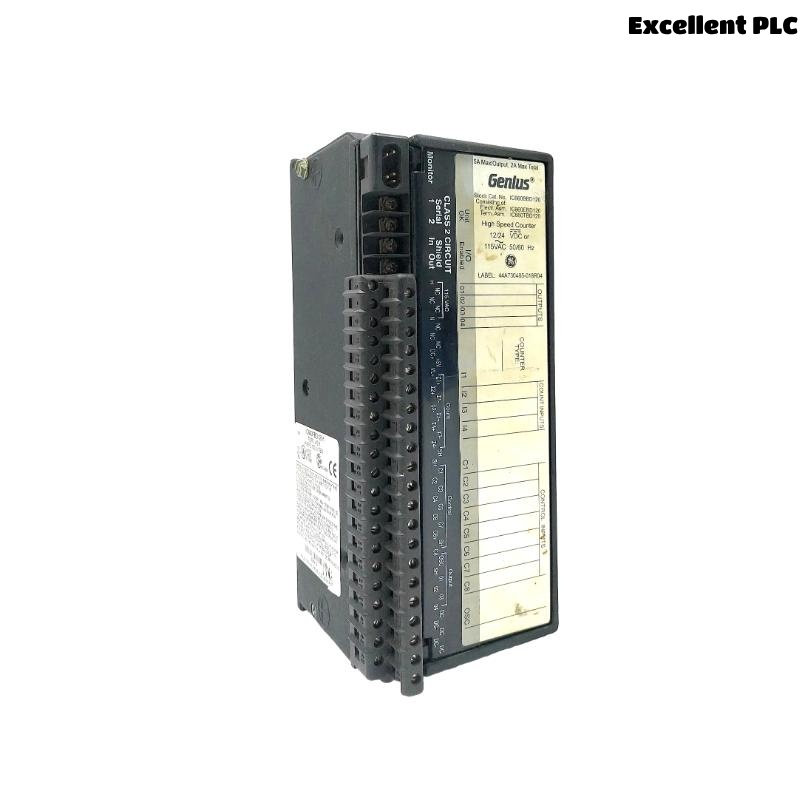

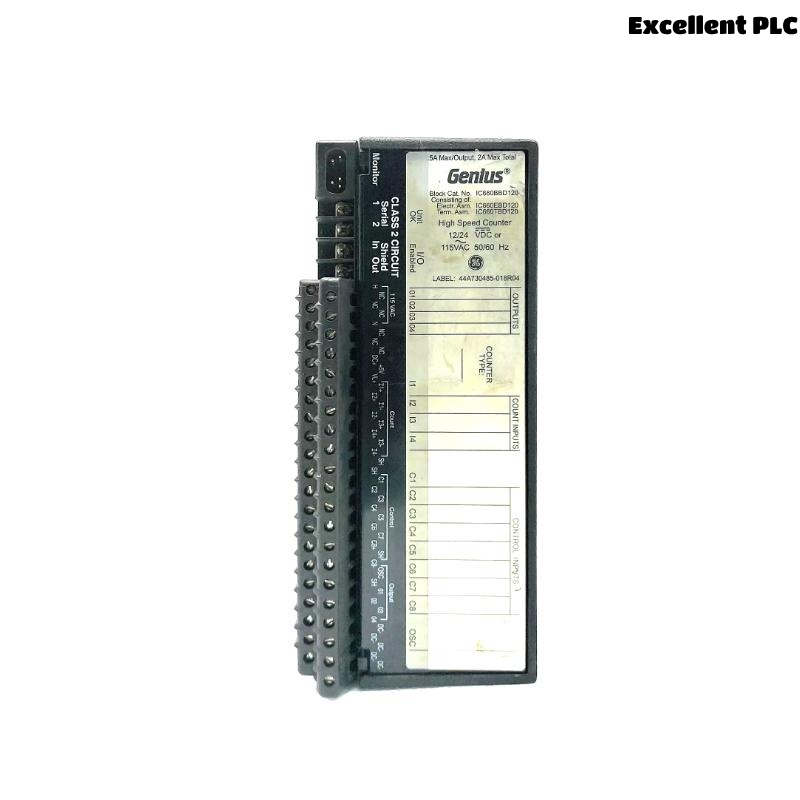

The GE IC660EBD120 I/O Block Electronic Assembly is a rugged and intelligent electronic interface unit designed as part of the GE Fanuc Genius I/O series. This device serves as the internal control and communication unit within a Genius I/O block, managing signal processing and communications between the field devices and host PLC or controller.

Designed to work in distributed control systems, the IC660EBD120 supports a wide range of discrete and analog modules. It is optimized for industrial environments requiring high-speed communication, efficient I/O control, and long-term durability. Whether integrated into a manufacturing plant or utility system, this unit provides the core intelligence for decentralized automation.

Product Specifications

| Specification | Detail |

|---|---|

| Model Number | IC660EBD120 |

| Manufacturer | GE Fanuc (General Electric) |

| Product Type | I/O Block Electronic Assembly |

| System Compatibility | GE Genius I/O Series |

| Communication Protocol | Genius Bus |

| Number of Channels | Supports up to 16 Discrete Inputs or Outputs |

| Input Voltage Range | 10.8 – 30 VDC (typical 24 VDC system) |

| Power Consumption | Approx. 3 W (module only) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% (non-condensing) |

| Dimensions (H × W × D) | 130 x 35 x 115 mm |

| Weight | 0.526 kg |

| Mounting Type | Panel or DIN rail |

| Diagnostics | Built-in fault detection and status indicators |

| Protection | Overvoltage, thermal, and reverse polarity |

| Certifications | UL, CE, CSA compliant |

Product Applications

The IC660EBD120 is well-suited for integration into a variety of industrial control and monitoring environments where reliable field I/O communication is critical. Common applications include:

-

Industrial Automation Systems: Interfaces sensors and actuators in factory automation processes.

-

Oil & Gas Facilities: Used in hazardous locations with intrinsically safe wiring.

-

Power Generation Plants: Supports distributed I/O in turbine and generator control.

-

Food and Beverage Processing: Ensures hygienic, safe automation and monitoring.

-

Material Handling Systems: Manages conveyor and robotic movement.

-

Building Management Systems (BMS): Controls HVAC, security, and energy systems.

Product Advantages

-

Integrated Intelligence: Embeds local decision-making capabilities and diagnostic functions.

-

Reliable Communication: Compatible with Genius Bus for high-speed, deterministic networking.

-

Modular Design: Easily replaceable without disturbing field wiring or mounting.

-

Flexible Input/Output Handling: Works with a wide range of discrete and analog devices.

-

Environmentally Robust: Performs reliably across wide temperature and humidity ranges.

-

Reduced Downtime: Built-in LED diagnostics and fault memory for quick troubleshooting.

-

Secure Mounting: Supports both DIN rail and panel installations for flexible deployment.

-

Long Product Lifecycle: GE’s industrial-grade engineering ensures long-term reliability.

-

Easy Integration: Seamlessly integrates with GE PLCs and other control systems.

-

Field-Proven Design: Trusted in thousands of industrial installations worldwide.

Frequently Asked Questions (FAQ)

-

What is the main function of the IC660EBD120?

It controls and processes input/output signals for a Genius I/O block and manages communication with the control system. -

Can this module be used with non-GE PLCs?

It is primarily designed for GE Genius I/O networks, but may be integrated with non-GE systems that support Genius protocols. -

Is this module hot-swappable?

No, it is not recommended to remove or install while the system is powered on. -

What voltage range does the IC660EBD120 support?

It supports 10.8 to 30 VDC input voltage, commonly used in 24V systems. -

Does the module include diagnostics?

Yes, it features onboard diagnostic LEDs and memory to help identify issues quickly. -

Can it be mounted vertically or horizontally?

Yes, it supports flexible mounting orientations including DIN rail and panel mounting. -

What’s the maximum number of I/O points this unit can control?

It supports up to 16 discrete I/O points depending on the I/O block configuration. -

Does the unit support harsh environments?

Yes, with an operating range up to 60°C and high humidity tolerance, it is ideal for industrial settings. -

Is configuration required before use?

Yes, it requires proper addressing and network configuration to operate within a Genius Bus system. -

How does the IC660EBD120 differ from IC660EBD110?

While both are I/O electronics modules, the IC660EBD120 typically supports higher input voltage ranges and added robustness for extended use.

Recommended Models – Related / Same Series

| Model Number | Description | Key Function | Compatibility |

|---|---|---|---|

| IC660EBD110 | I/O Block Electronics | Core I/O processing unit | GE Genius I/O |

| IC660TBD100 | Terminal Block Assembly | Connects field wiring | GE Genius I/O |

| IC660BBD120 | 16-Circuit Sink I/O Block | Discrete input block | GE Genius I/O |

| IC660BBD110 | 16-Circuit Source I/O Block | Discrete output block | GE Genius I/O |

| IC660TSD100 | I/O Block Terminal Assembly | Screw terminal I/O block | GE Genius I/O |

| IC660BRD025 | Analog Output Block (0-10V) | Sends analog signals to actuators | GE Genius I/O |

Popular GE Automation Models (Same Brand)

| Model Number | Description | Primary Use | Series |

|---|---|---|---|

| IC693CPU364 | High-performance CPU Module | PLC logic processing | Series 90-30 |

| IC695CPE310 | PACSystems RX3i Controller | High-speed control | RX3i |

| IC200ALG320 | Analog Input Module (8-channel) | Analog data acquisition | VersaMax I/O |

| IC200MDL740 | 16-point Output Module | Digital signal control | VersaMax I/O |

| IC695PSA140 | Power Supply Module | Supplies regulated power | RX3i |

| IC670GBI102 | Genius Bus Interface Unit | Genius I/O network communication | Field Control Series |

Excellent PLC

Excellent PLC