| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

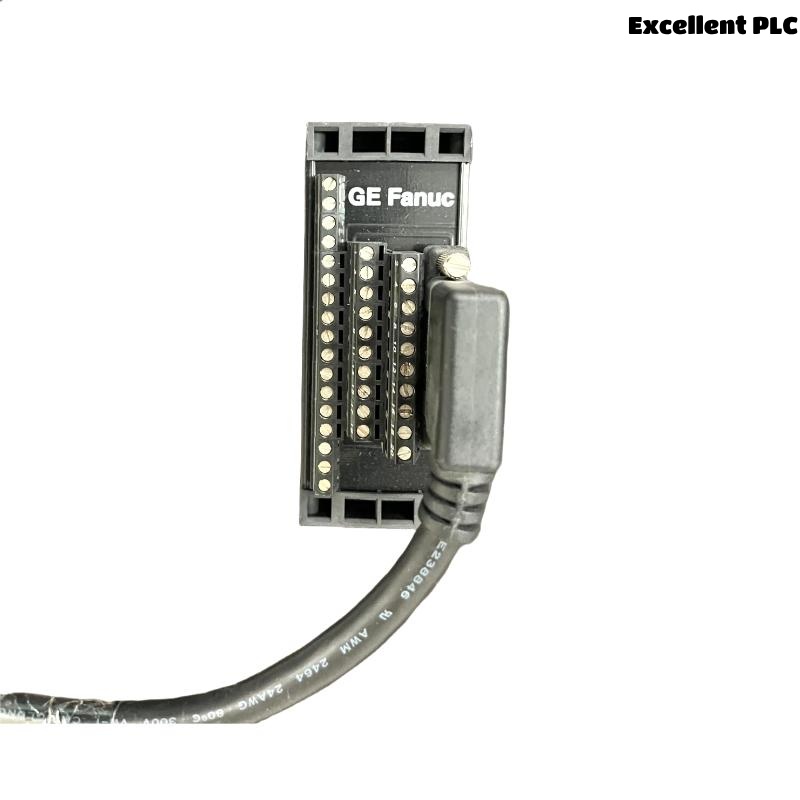

The GE IC693ACC334 I/O Face Plate is a crucial component designed for use with the GE 90-30 Series programmable logic controller (PLC) system. It serves as an essential interface between the I/O modules and the field wiring. The I/O Face Plate provides a neat and organized termination point for wiring, offering both aesthetic and functional benefits in industrial control systems. The plate is engineered for reliability and ease of use, providing clear labeling, excellent durability, and a secure connection for I/O modules.

Typically, the I/O Face Plate is used in applications that involve monitoring and controlling field devices such as sensors, actuators, and switches. With its modular design, the IC693ACC334 allows for easy integration into existing control systems, making it a versatile solution for a wide range of industrial automation needs.

Designed to complement the GE 90-30 PLC series, this faceplate enhances the overall functionality and reliability of your control system. Whether you are upgrading an existing setup or building a new one, the IC693ACC334 ensures efficient operation and ease of maintenance, with clear labeling and secure connections.

Product Specifications

The following table presents the technical specifications of the GE IC693ACC334 I/O Face Plate:

| Specification | Details |

|---|---|

| Model Number | IC693ACC334 I/O Face Plate |

| Type | I/O Face Plate |

| Dimensions (H x W x D) | 117.86 x 57 x 45 mm |

| Weight | 0.045 kg |

| Material | High-Quality ABS Plastic |

| Mounting Type | Front mounting on I/O module |

| Operating Temperature Range | -20°C to +60°C |

| Storage Temperature Range | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Compatibility | Compatible with GE 90-30 I/O Modules |

| Connection Type | Screw Terminals for Wire Connections |

| Electrical Rating | 24V DC |

| Color | Black |

| Certifications | UL, CE, RoHS Compliant |

Applications of the GE IC693ACC334 I/O Face Plate

The GE IC693ACC334 I/O Face Plate is an essential component for a wide variety of industrial applications, where high-performance automation and I/O connectivity are needed. The following are some of the primary use cases:

-

Factory Automation: The I/O face plate provides a secure and organized connection for I/O modules in factory automation systems, enabling seamless control over production lines, assembly processes, and packaging systems.

-

Process Control Systems: Used in industries such as chemical processing, oil & gas, and pharmaceuticals, the faceplate helps integrate sensors and actuators for continuous monitoring and control of processes.

-

Building Automation: For building management systems (BMS), the IC693ACC334 I/O faceplate is used to interface with HVAC systems, lighting controls, energy management, and fire alarm systems.

-

Safety Systems: The IC693ACC334 faceplate ensures that critical safety equipment such as emergency stop buttons, alarms, and safety sensors can be connected reliably, maintaining the integrity of emergency shutdown systems.

-

Energy Management Systems: This faceplate plays a key role in connecting energy metering devices and communication modules, enabling effective monitoring and management of energy consumption in large industrial setups.

-

SCADA Systems: The IC693ACC334 I/O faceplate is integral in SCADA systems for real-time data collection, monitoring, and control of remote industrial processes.

Advantages of the GE IC693ACC334 I/O Face Plate

-

Durable Construction: Made of high-quality ABS plastic, the IC693ACC334 is designed to withstand harsh industrial environments, ensuring a long lifespan and minimal wear and tear.

-

Easy Installation: The front-mount design makes it simple to install and remove, saving valuable time during system setup or maintenance.

-

Clear Labeling: The faceplate provides clear, readable labels for I/O connections, which simplifies troubleshooting and system upgrades.

-

Organized Wiring: The IC693ACC334 ensures that wiring is neatly terminated, reducing the risk of errors or damage to connections.

-

Versatile Compatibility: This faceplate is compatible with a wide range of GE 90-30 I/O modules, ensuring that it can be easily integrated into existing or new automation systems.

-

Compact Design: Its compact size ensures that it fits into control cabinets with limited space, offering a space-saving solution without sacrificing functionality.

-

Cost-Effective: The faceplate offers a low-cost yet essential solution for securing and organizing wiring in your industrial control system.

-

Improved Maintenance: With organized and labeled connections, maintaining and troubleshooting the system becomes faster and more efficient.

-

Enhanced Safety: By ensuring that all connections are securely and clearly labeled, it reduces the chance of wiring errors that could lead to system malfunctions or safety risks.

-

Low Maintenance: Due to its robust construction, the IC693ACC334 requires little to no maintenance, reducing downtime and service costs.

Frequently Asked Questions (FAQ)

-

What is the GE IC693ACC334 I/O Face Plate used for?

-

It is used to organize and terminate I/O connections between I/O modules and field devices in a GE 90-30 PLC system.

-

-

How do I install the GE IC693ACC334 I/O Face Plate?

-

The faceplate mounts directly to the front of the I/O module, providing a secure and organized connection for the wiring.

-

-

What is the weight of the IC693ACC334 I/O Face Plate?

-

The faceplate weighs 0.045 kg.

-

-

What materials is the IC693ACC334 I/O Face Plate made of?

-

The faceplate is made of high-quality ABS plastic, ensuring durability and resistance to environmental factors.

-

-

Can the IC693ACC334 be used with other GE PLC systems?

-

The IC693ACC334 is specifically designed for use with GE 90-30 PLC modules and may not be compatible with other series.

-

-

What is the operating temperature range for the I/O Face Plate?

-

The IC693ACC334 operates within a temperature range of -20°C to +60°C.

-

-

Is the IC693ACC334 I/O Face Plate easy to maintain?

-

Yes, the faceplate requires minimal maintenance due to its durable construction and organized wiring system.

-

-

What types of connections are supported by the IC693ACC334 I/O Face Plate?

-

The faceplate supports screw terminal connections for wiring.

-

-

Is the IC693ACC334 UL and CE certified?

-

Yes, the IC693ACC334 is UL and CE certified, ensuring it meets international safety and quality standards.

-

-

What is the size of the IC693ACC334 I/O Face Plate?

-

The faceplate has dimensions of 117.86 x 57 x 45 mm.

-

Recommended Related Models

Here are six models that are related to the GE IC693ACC334 I/O Face Plate in the GE 90-30 series or have similar functionalities:

| Model | Description | Key Features |

|---|---|---|

| GE IC693ACC332 | I/O Terminal Block Base | Connects I/O modules to field devices |

| GE IC693ACC330 | Compact I/O Expansion Module | Compact module for small I/O setups |

| GE IC693ACC340 | I/O Base with Terminal Block | Modular I/O base for flexible control systems |

| GE IC693MDL750 | 16-Point Relay Output Module | Provides relay outputs for automation |

| GE IC693MDL740 | 32-Point Digital Input Module | High-density digital input module |

| GE IC693CMM321 | Ethernet Communication Module | Provides Ethernet communication for PLCs |

Popular GE Models

Here are six other highly popular models from GE that are widely used in industrial automation:

| Model | Description | Key Features |

|---|---|---|

| GE IC693CMM311 | Serial Communication Module | RS-232/RS-485 serial communication support |

| GE IC693PWR330 | Power Supply Module | Provides stable power to GE PLC systems |

| GE IC693MDL750 | Relay Output Module | Outputs relay-controlled signals to devices |

| GE IC693CPU313 | Central Processing Unit | High-performance CPU for automation control |

| GE IC693MDL742 | 32-Point Digital Output Module | 32-point module for digital outputs |

| GE IC693CMM321 | Ethernet Communication Module | Allows Ethernet communication for remote control |

Excellent PLC

Excellent PLC