| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

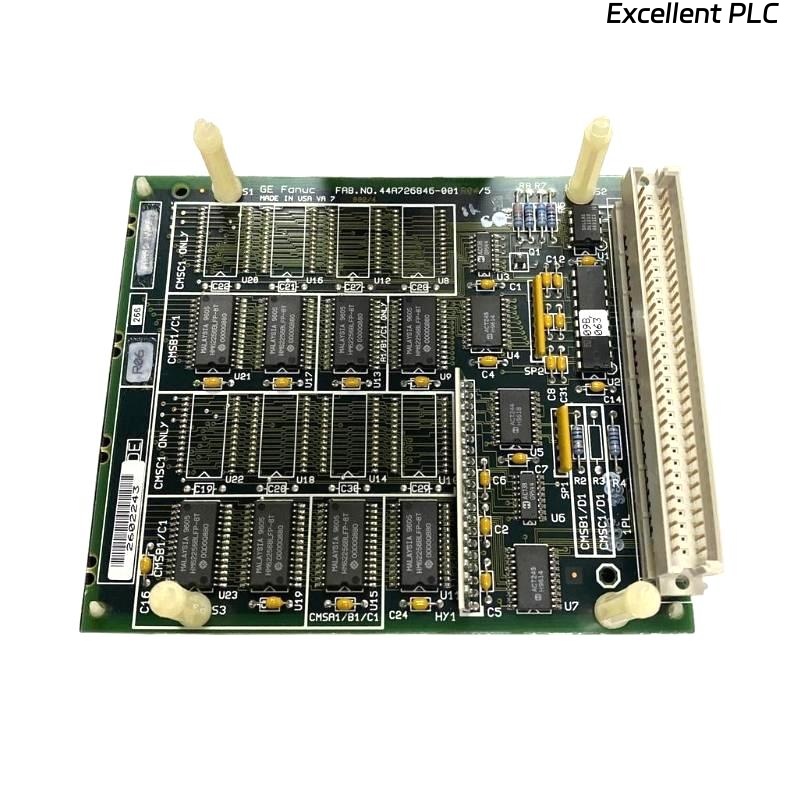

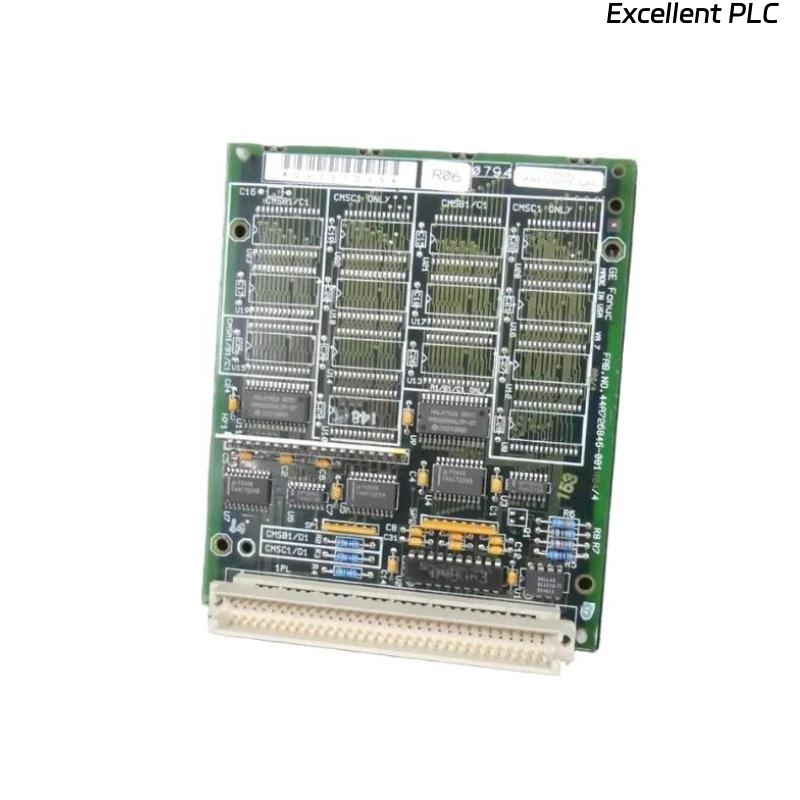

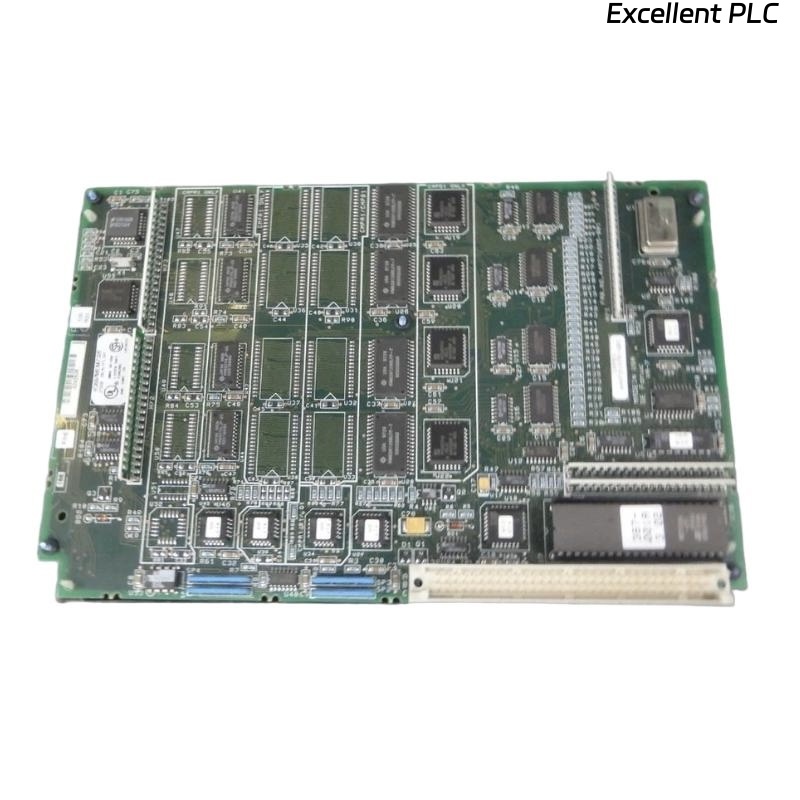

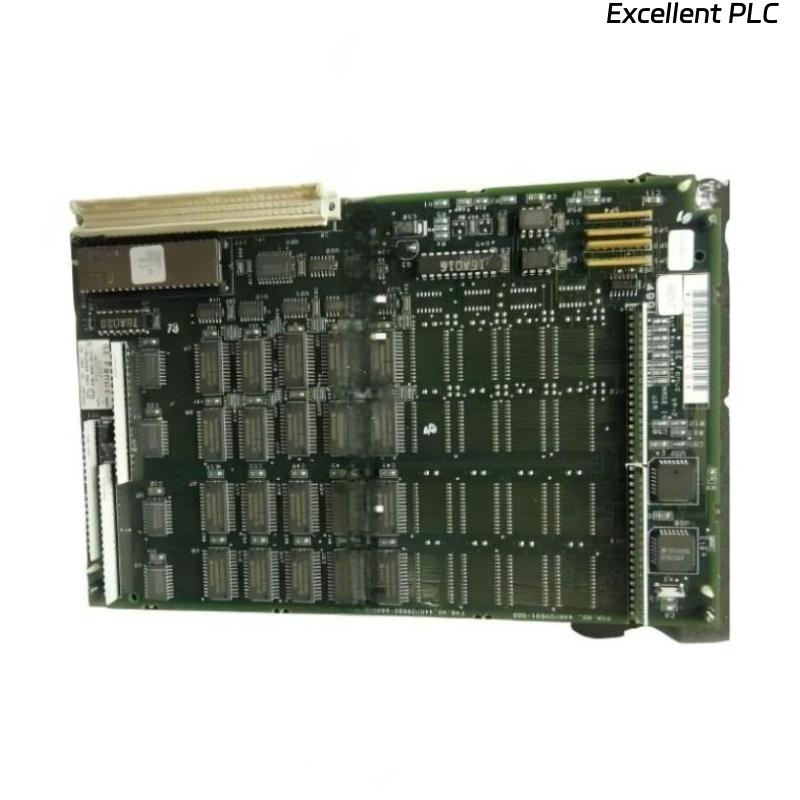

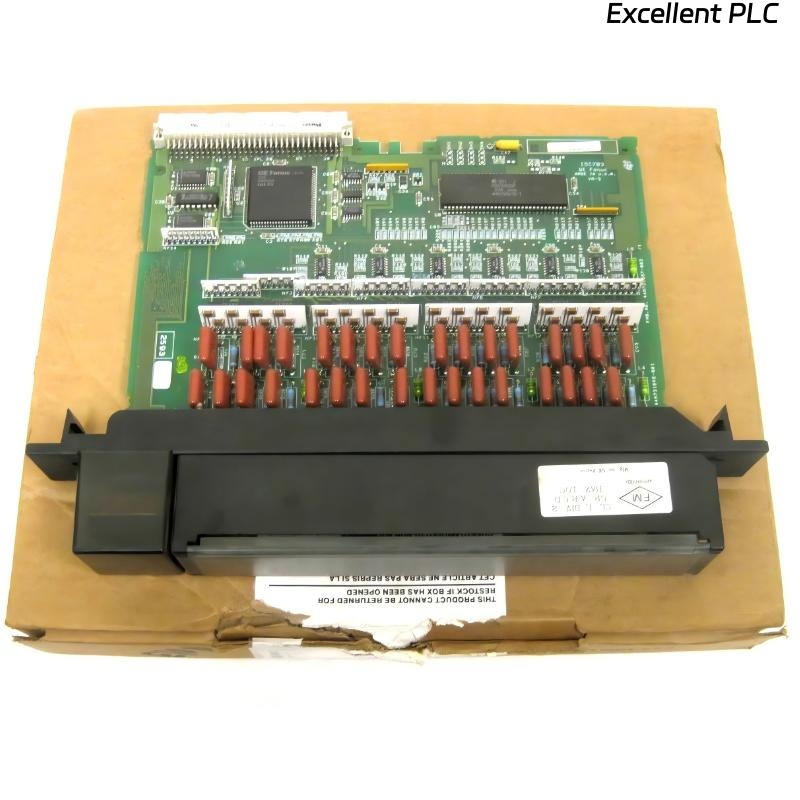

The GE IC693PCM300 Programmable Coprocessor Module (PCM) is a highly versatile and powerful coprocessor designed to significantly expand the processing capabilities of the GE Fanuc Series 90-30 PLC system. The PCM functions as a dedicated, intelligent module capable of executing complex control tasks, handling communication protocols, and offloading computation-heavy routines from the main PLC CPU.

Equipped with a dedicated Intel 80C186 microprocessor and onboard memory, the IC693PCM300 provides a flexible environment for executing C, C++, or Basic programming. It allows engineers to develop custom applications that run independently or interact with the PLC logic, enabling advanced process control, data management, or custom protocol support that would otherwise burden the main controller.

With built-in serial ports for RS-232 and RS-485 communication, the IC693PCM300 can also function as a communication gateway between PLC systems and external devices such as bar code readers, printers, sensors, drives, or legacy control equipment. Its modular design and high reliability make it ideal for enhancing both new and existing GE 90-30 automation systems.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | IC693PCM300 |

| Product Type | Programmable Coprocessor Module |

| Compatible PLC | GE Fanuc Series 90-30 PLC |

| Processor Type | Intel 80C186 microprocessor |

| Operating Frequency | 12 MHz |

| Program Memory | 192 KB user-programmable FLASH memory |

| Data Memory | 128 KB battery-backed SRAM |

| Serial Ports | 2 x serial ports (COM1 and COM2) |

| Serial Interface Types | RS-232, RS-485, configurable |

| Serial Port Data Rates | 300 to 38.4 Kbps |

| Programming Languages | C, C++, BASIC |

| Firmware Upgradable | Yes |

| Supported Communication Protocols | Modbus RTU, ASCII, custom protocols |

| Backplane Interface | High-speed connection to PLC backplane |

| Power Supply | 5 VDC from PLC backplane |

| Power Consumption | 500 mA @ 5 VDC |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature Range | -40°C to +85°C |

| Humidity Range | 5% to 95% non-condensing |

| Module Dimensions (H x W x D) | 150 x 100 x 25 mm |

| Weight | 0.318 kg |

| Mounting Method | Installed in Series 90-30 PLC rack |

| Certifications | UL, CSA, CE, RoHS |

Applications

-

Advanced Process Control: Executes complex calculations and algorithms independently of the main CPU.

-

Data Logging: Stores, formats, and communicates large amounts of process data.

-

Protocol Conversion: Converts non-native protocols for communication with third-party devices.

-

Custom Control Functions: Executes custom applications in C, C++, or BASIC for specialized processes.

-

Legacy Device Integration: Interfaces with serial devices (RS-232/RS-485), including sensors, bar code readers, and older equipment.

-

SCADA Communication: Serves as a communication gateway between PLCs and SCADA/HMI systems.

-

OEM Machinery: Provides OEMs with a powerful programming platform for creating machine-specific control logic.

-

Energy Monitoring: Gathers and formats data from power meters and analyzers for use in energy management systems.

-

Batch Control: Manages batch recipes and process sequences for industries such as food, beverage, and chemical processing.

-

Event-driven Automation: Handles real-time events and triggers actions without burdening the PLC CPU.

Product Advantages

-

Dedicated Processing Power: Frees up PLC CPU resources by handling complex or time-intensive tasks on its own processor.

-

Versatile Programming: Supports C, C++, and BASIC languages for full application flexibility.

-

Independent Operation: Runs applications independently of PLC scan time, ideal for time-critical operations.

-

Serial Connectivity: Dual serial ports enable easy integration with external equipment using RS-232 or RS-485.

-

Protocol Support: Enables Modbus RTU, ASCII, and user-defined protocols for communication with a wide range of devices.

-

Compact Design: Installs directly into Series 90-30 racks, maintaining a space-efficient control architecture.

-

Rugged Industrial Build: Engineered for reliable operation in demanding industrial environments.

-

User-expandable Memory: Provides onboard Flash and battery-backed SRAM for storing programs and data.

-

Extends PLC Capabilities: Enhances existing 90-30 PLCs with advanced processing and communication features.

-

Proven Technology: Widely used in various industries including manufacturing, utilities, process industries, and OEM equipment.

Frequently Asked Questions (FAQ)

-

What is the purpose of the IC693PCM300?

It is a programmable coprocessor that adds dedicated processing capability to a Series 90-30 PLC system. -

What programming languages can be used?

It supports programming in C, C++, and BASIC. -

Can it operate independently of the PLC CPU?

Yes, it runs applications independently and can interact with the PLC only when needed. -

What type of serial communication is supported?

The module offers two configurable serial ports that support RS-232 or RS-485. -

Is it suitable for protocol conversion?

Yes, it is commonly used for protocol conversion and integration of legacy devices. -

Does it require external power?

No, it draws 5 VDC power from the PLC backplane. -

Can the firmware be updated?

Yes, the module supports firmware upgrades. -

How much program and data memory is available?

It provides 192 KB of Flash memory for user programs and 128 KB of SRAM for data. -

Is the IC693PCM300 compatible with modern SCADA systems?

Yes, it can act as a communication gateway for SCADA/HMI applications. -

In what industries is this module commonly used?

It is widely used in manufacturing, process control, OEM machine building, utilities, and energy sectors.

Recommended Related Models (Same Series or Similar)

| Model Number | Description | Notes |

|---|---|---|

| IC693PCM301 | PCM with higher memory capacity | Enhanced version of PCM300 |

| IC693CPU374 | CPU374 Plus Ethernet PLC CPU | Advanced PLC CPU with Ethernet |

| IC693NIU004 | Ethernet Network Interface Unit | Adds Ethernet capability |

| IC693CMM321 | Genius Communications Module | For Genius I/O network |

| IC693PBS201 | PROFIBUS DP Slave Module | PROFIBUS connectivity |

| IC693CMM302 | PROFIBUS Master Module | PROFIBUS DP master capability |

Popular GE Automation Models (Same Brand)

| Model Number | Description | Application |

|---|---|---|

| IC695CPE330 | RX3i CPU with Ethernet | High-speed PAC with Ethernet |

| IC695NIU001 | RX3i Network Interface Unit | Remote I/O interface |

| IC695PBM300 | RX3i PROFIBUS Master Module | PROFIBUS DP master |

| IC695ETM001 | RX3i Ethernet Module | Ethernet networking |

| IC697CPU772 | Series 90-70 CPU | High-performance PLC CPU |

| IC200ERM002 | VersaMax Ethernet Remote I/O Master | Remote I/O for VersaMax |

Excellent PLC

Excellent PLC