| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

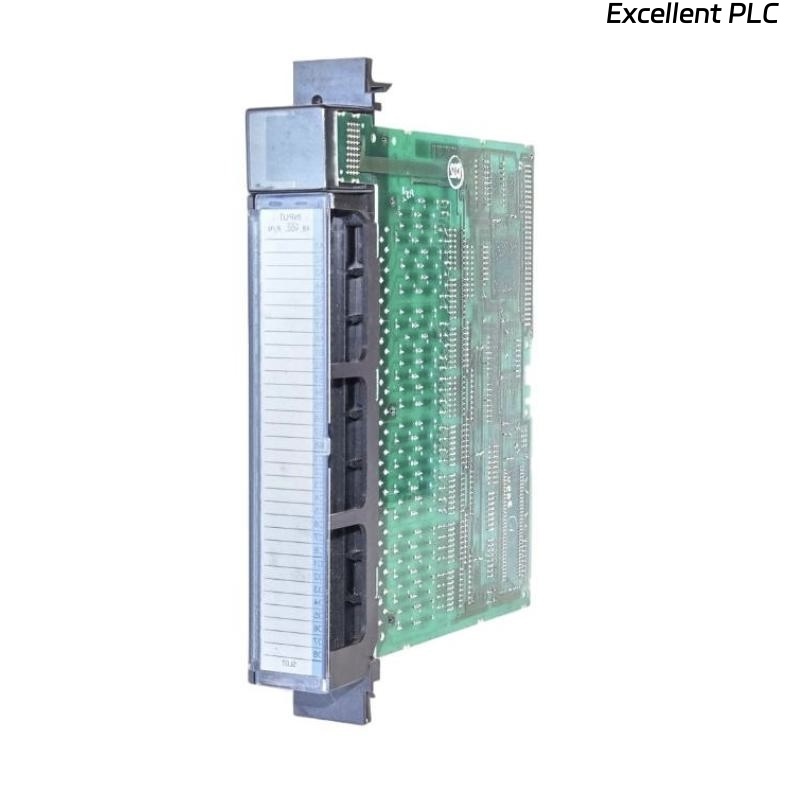

The GE IC693PIF350 Interface Card is a high-performance industrial communication module designed for use with the GE Fanuc Series 90-30 PLC platform. Its primary purpose is to provide a flexible and programmable communication interface between the PLC and a wide range of external devices, third-party systems, and specialized equipment.

The IC693PIF350 is ideal for applications where standard PLC communication options are insufficient or where specialized or legacy devices require unique interface configurations. The module supports multiple communication standards—including RS-232, RS-422, and RS-485—with configurable settings for baud rate, data bits, parity, and stop bits.

The card is a perfect solution for protocol conversion, custom device interfacing, and extending the life of existing control systems. It also helps improve plant efficiency by integrating non-native devices into modern control architectures without requiring major hardware upgrades.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | IC693PIF350 |

| Product Type | Programmable Interface Card |

| Compatible PLC | GE Fanuc Series 90-30 PLC |

| Communication Ports | 1 programmable interface port |

| Interface Options | RS-232, RS-422, RS-485 |

| Baud Rate | 300 bps to 38.4 kbps |

| Communication Protocols | Modbus RTU, ASCII, user-defined protocols |

| Isolation | Optical isolation for electrical safety |

| Power Supply | 5 VDC supplied by PLC backplane |

| Power Consumption | 450 mA @ 5 VDC |

| Configuration Software | GE Proficy Machine Edition or equivalent |

| Diagnostic Indicators | LED indicators for power and communication status |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature Range | -40°C to +85°C |

| Humidity Range | 5% to 95% non-condensing |

| Dimensions (H x W x D) | 102.5 x 82 x 80 mm |

| Weight | 0.612 kg |

| Mounting Method | Series 90-30 PLC rack |

| Certifications | UL, CSA, CE, RoHS |

Applications

-

Device Integration: Connects Series 90-30 PLCs with various third-party devices, including custom sensors and controllers.

-

Protocol Bridging: Converts between proprietary/legacy protocols and modern PLC communication standards.

-

SCADA and HMI Gateways: Facilitates efficient data exchange between the PLC and supervisory control systems.

-

Legacy Device Support: Maintains compatibility with older devices via RS-232, RS-422, and RS-485.

-

OEM Solutions: Provides flexible interfacing for custom-built OEM equipment.

-

Machine Retrofits: Modernizes legacy equipment with new control capabilities.

-

Energy Monitoring: Interfaces with power meters and analyzers for real-time energy management.

-

Batch Processing: Supports the coordination of batch control processes by linking PLCs with field devices.

-

Safety Systems: Connects PLCs to safety-related devices such as interlocks and emergency shutdown systems.

-

Data Acquisition: Enables real-time data collection from field devices for analysis and reporting.

Product Advantages

-

Multiple Interface Standards: Supports RS-232, RS-422, and RS-485 for broad connectivity.

-

High Reliability: Engineered for continuous operation in demanding industrial environments.

-

Electrical Isolation: Optical isolation ensures safe and noise-free communication.

-

User Programmability: Allows development of custom protocols for unique device integration.

-

Seamless PLC Integration: Installs directly into Series 90-30 racks—no external wiring required.

-

Flexible Configuration: Easily configured with GE Proficy Machine Edition or similar tools.

-

Cost Savings: Adds communication capabilities without the need for full system replacement.

-

Field-Proven: Trusted in industries such as manufacturing, utilities, oil & gas, and process control.

-

Diagnostic Features: Built-in LEDs provide status and troubleshooting information.

-

Extended Equipment Life: Supports ongoing use of legacy devices in modern automation systems.

Frequently Asked Questions (FAQ)

-

What does the IC693PIF350 do?

It acts as a communication interface card, enabling the Series 90-30 PLC to connect to external devices. -

Which serial protocols are supported?

RS-232, RS-422, and RS-485 are all supported. -

Can I configure custom protocols?

Yes, user-defined protocols are fully supported. -

Does the module offer electrical isolation?

Yes, optical isolation is built-in for noise immunity and safety. -

What software is used for configuration?

GE Proficy Machine Edition or compatible tools can configure the module. -

What is the supported baud rate?

300 bps up to 38.4 kbps. -

Can it communicate with SCADA systems?

Yes, it serves as a gateway to SCADA and HMI platforms. -

Is the card suitable for legacy device integration?

Yes, it excels at interfacing with older serial devices. -

What kind of diagnostic feedback does it provide?

LED indicators show power and communication status. -

What industries use the IC693PIF350?

Common industries include manufacturing, energy, process control, and OEM equipment.

Recommended Related Models (Same Series or Similar)

| Model Number | Description | Notes |

|---|---|---|

| IC693PIF301 | Programmable Interface Card | Standard model |

| IC693PCM311 | Programmable Coprocessor Module | Advanced processing and control |

| IC693CMM321 | Genius Communications Module | Genius I/O networking |

| IC693PBS201 | PROFIBUS DP Slave Module | PROFIBUS connectivity |

| IC693NIU004 | Ethernet Network Interface Unit | Adds Ethernet capability |

| IC693CPU374 | CPU374 Plus Ethernet PLC CPU | Advanced PLC CPU |

Popular GE Automation Models (Same Brand)

| Model Number | Description | Application |

|---|---|---|

| IC695CPE330 | RX3i CPU with Ethernet | High-performance PAC CPU |

| IC695NIU001 | RX3i Network Interface Unit | Remote I/O controller |

| IC695PBM300 | RX3i PROFIBUS Master Module | PROFIBUS DP master |

| IC695ETM001 | RX3i Ethernet Module | Ethernet networking |

| IC697CPU772 | Series 90-70 CPU | Large PLC controller |

| IC200ERM002 | VersaMax Ethernet Remote I/O Master | Remote I/O for VersaMax system |

Excellent PLC

Excellent PLC