| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

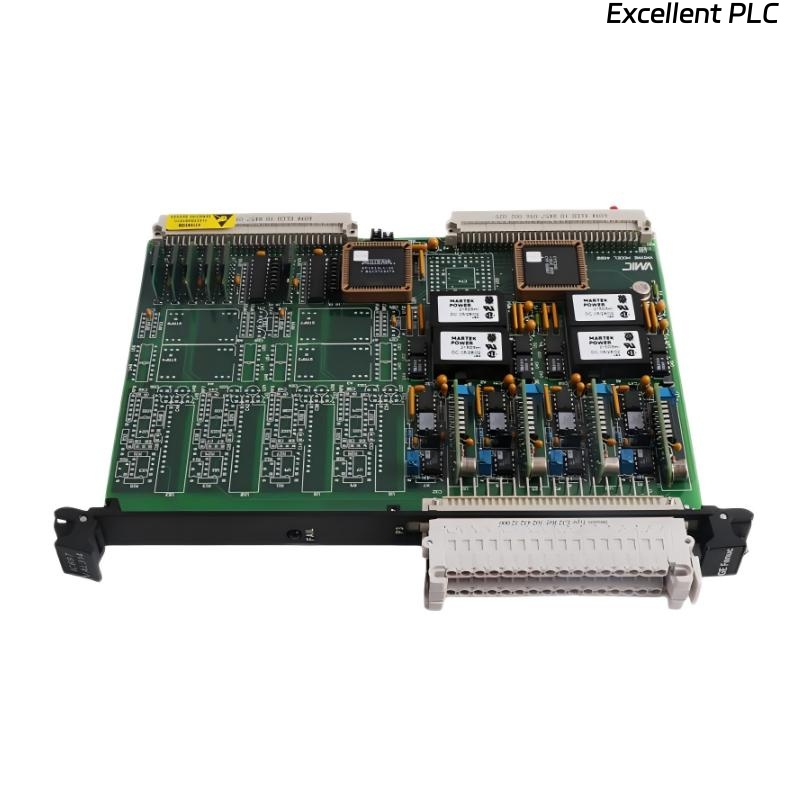

The GE IS200GFOIH1A is a Gate Feedback and Output Interface Board designed as part of GE’s advanced Mark VI turbine control system. This printed circuit board (PCB) acts as a crucial intermediary between the controller and power bridge circuits in variable-speed drive systems. Its main role is to transmit and receive IGBT gate signals and feedback, enabling efficient control over high-power motor and generator operations.

This board is used in pulse-width modulation (PWM)-based applications where accurate and reliable gate control is essential. Engineered for industrial-grade performance, the IS200GFOIH1A supports high-speed communication, galvanic isolation, and noise immunity—essential features for harsh industrial settings such as power plants and heavy manufacturing facilities.

Product Specifications

| Parameter | Details |

|---|---|

| Product Model | IS200GFOIH1A |

| Manufacturer | General Electric (GE) |

| Product Family | Mark VI Speedtronic |

| Product Type | Gate Feedback and Output Interface Board |

| Function | Transmits gate drive signals; receives feedback from IGBT gate circuits |

| Input Type | Digital PWM control signals |

| Output Type | Gate trigger signals, status feedback |

| Galvanic Isolation | Yes (between control and power sections) |

| Signal Channels | 6 output gate channels with feedback per channel |

| Communication Interface | Ribbon cable (to power interface board), fiber or copper gate cable |

| Operating Voltage | 5V logic signal control; interfaces with high-voltage gates |

| Mounting Style | Rack-mounted (via drive system backplane) |

| Operating Temperature | -20°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% non-condensing |

| Dimensions | 320 x 250 x 50 mm |

| Weight | 0.5 kg |

| Cooling Requirement | Convection or forced air (system dependent) |

| Certifications | UL, CE, RoHS |

| Compatibility | GE Mark VI and related PWM-based power bridge systems |

| Diagnostic LEDs | Yes (per channel: Status, Fault) |

| Maintenance Access | Hot-swappable in supported drive configurations |

Product Applications

The GE IS200GFOIH1A is widely implemented in industrial drive systems where precise control of IGBT gate firing and feedback is essential. Its applications span across:

-

Gas and Steam Turbine Generator Control

-

Industrial Variable Frequency Drives (VFDs)

-

High-Voltage Inverter Bridge Circuits

-

HVAC and Motor Drive Systems

-

Pumped Storage Hydropower Plants

-

Marine Propulsion Power Control

-

Heavy Manufacturing Process Lines

Product Advantages

-

Robust Gate Signal Management

Offers reliable delivery and monitoring of gate signals across six IGBT channels, ensuring accurate switching in power bridges. -

Enhanced Signal Isolation

Galvanic isolation between control logic and power stages protects sensitive control electronics from electrical transients and noise. -

Designed for Harsh Environments

Conformally coated for protection against humidity, dust, and chemical exposure—ideal for demanding industrial environments. -

Diagnostic-Ready Architecture

Built-in LED indicators on each channel simplify operational diagnostics and reduce troubleshooting time. -

Part of the Proven Mark VI Ecosystem

Seamless integration with Mark VI control systems reduces configuration complexity and enhances operational consistency. -

Modular and Maintainable

Supports easy module replacement and upgrade without requiring system-wide shutdowns, especially in drive rack systems.

FAQ

-

What type of devices does the IS200GFOIH1A interface with?

It interfaces with IGBT modules in power converter bridges for motor and turbine drive applications. -

How many gate signals can the board manage simultaneously?

It supports six independent gate outputs, each with its own feedback circuit for fault detection. -

Is the board capable of detecting gate failures or faults?

Yes, the board receives feedback from each gate to monitor failures, which can then trigger protective system responses. -

How is galvanic isolation implemented?

Isolation is achieved through opto-isolators and transformers, separating low-voltage logic from high-voltage power domains. -

Does this board support redundant signal paths?

It depends on system design. Redundancy can be achieved by paralleling or replicating gate paths in the controller. -

What kind of fault signals can the board detect?

It detects gate under-voltage, gate over-temperature, and signal loss from IGBT modules. -

Is there a synchronization mechanism with the control processor?

Yes, gate signals are synchronized with PWM logic cycles generated by the Mark VI control processor. -

What happens in the event of signal degradation?

The system triggers an automatic shutdown or failsafe mode, depending on how the diagnostic thresholds are configured. -

How is this board connected to the Mark VI controller?

Via ribbon cable or backplane interface, which connects it to the VME bus or power interface controller. -

Can this board be tested independently?

Yes, offline simulation and test equipment can be used to verify gate signals and feedback without full system integration.

Related Models from the Same Series

| Model Number | Description | Primary Function |

|---|---|---|

| IS200GDBBH1A | Gate Distribution Board | Distributes gate commands |

| IS200GGIHC1B | Gate Generator Interface Board | IGBT gate signal generation |

| IS200DSPXH1D | Digital Signal Processor Board | Controls PWM signal generation |

| IS200EACFG2A | Analog I/O Card | Signal conditioning and acquisition |

| IS200SPROH1A | Signal Processor Board | High-speed signal processing |

| IS200BICLH1A | Bridge Interface Control Board | Power interface and control signaling |

Popular Models from the GE Brand

| Model Number | Description | System Compatibility |

|---|---|---|

| DS200TCQAG1B | Analog Input Board | Speedtronic Mark V |

| DS215UCVAG1A | VME Processor Board | GE Control Systems |

| IS200TREGH1B | Trip Emergency Gas Board | Mark VI Trip Control |

| DS200LDCCH1A | LAN Communication Control Board | Mark V Turbine Control |

| DS200PCCAG5ACB | Power Converter Interface Card | Drive Systems |

| IS200VCRCH1B | VCRC Communication Interface | Mark VI and Mark VIe |

Excellent PLC

Excellent PLC