| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

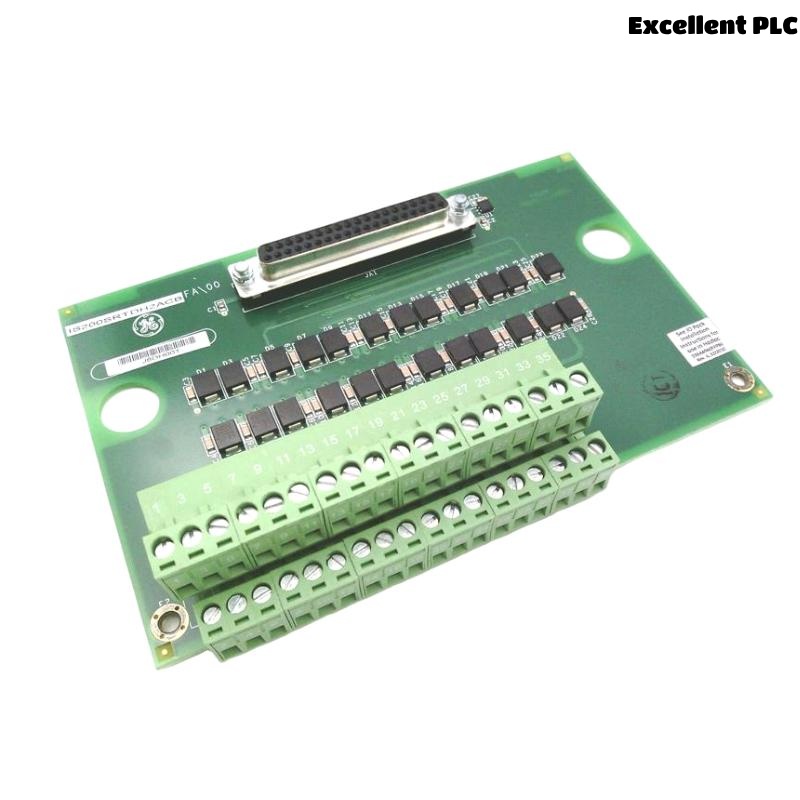

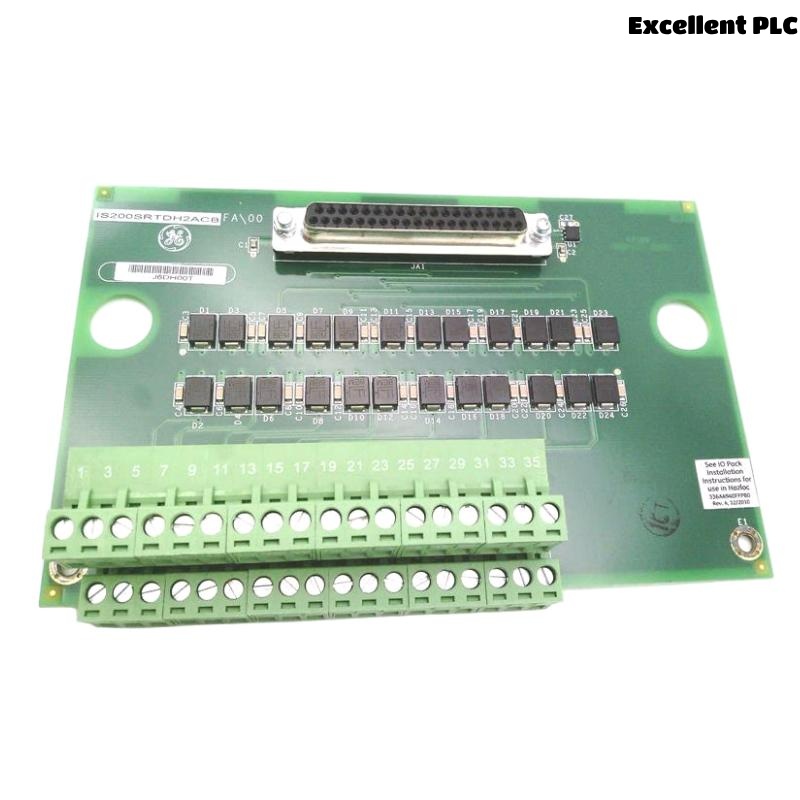

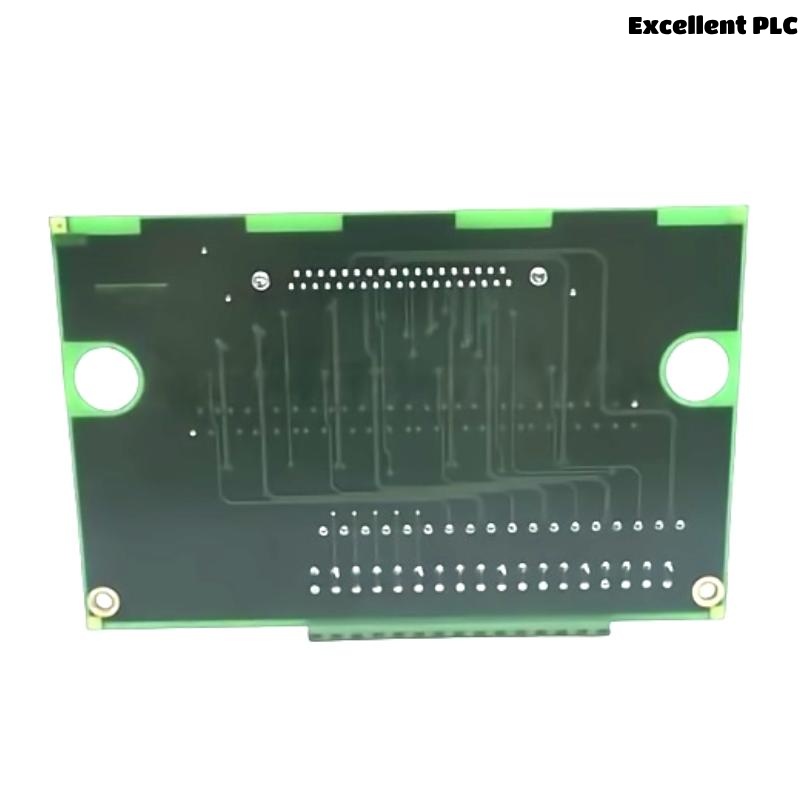

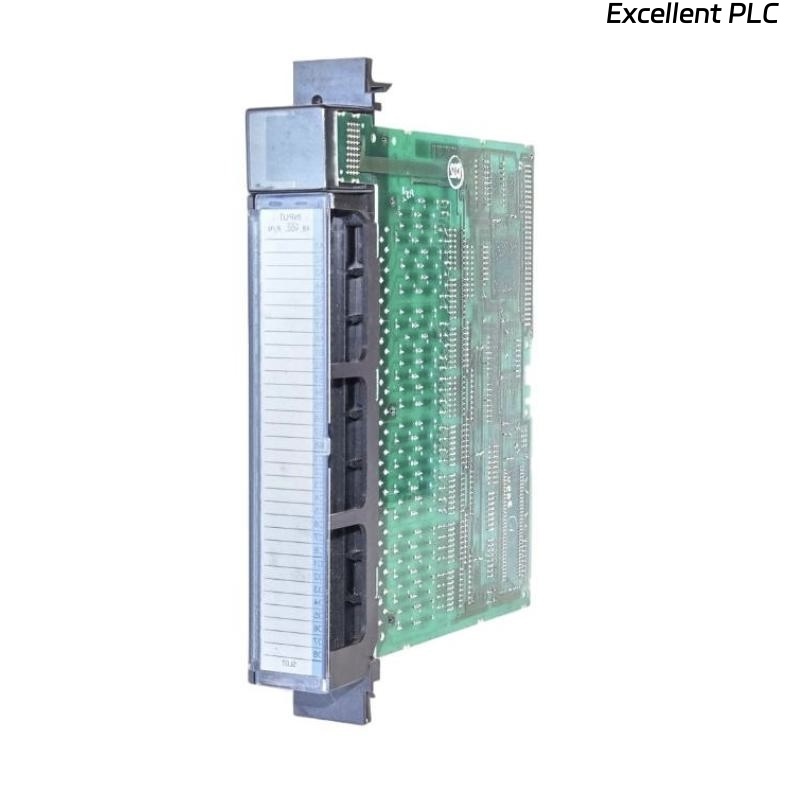

The GE IS200SRTDH2A Compact RTD Terminal Board is a precision temperature signal interface module designed specifically for GE Mark VI turbine control systems. It provides a reliable connection point for resistance temperature detectors (RTDs), converting field sensor inputs into the precise temperature data required for turbine, generator, and industrial process control applications.

This terminal block has been carefully designed to ensure low-noise signal transmission, strong isolation performance, and seamless integration with GE control systems. Its compact design makes it ideal for installations with limited panel space, while maintaining high channel density and reliable performance in critical monitoring environments.

Product Specifications

| scope | value |

|---|---|

| model | IS200SRTDH2A |

| Manufacturer | General Electric (GE) |

| Product Type | Compact RTD Terminal Blocks |

| System compatibility | GE Mark VI Steam Turbine Control System |

| Supported sensors | 2-wire, 3-wire, and 4-wire RTDs |

| Number of channels | 12 RTD input channels |

| Input signal range | -200°C to +850°C (depending on sensor) |

| Excitation current | Programmable to optimize RTD linearity |

| Signal Isolation | Channel-to-channel and channel-to-channel isolation |

| Noise suppression | High common-mode and differential-mode noise rejection |

| Wiring method | Screw terminal connection |

| diagnosis | Channel status and fault monitoring |

| Operating temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5%–95% non-condensing |

| EMC Compliance | IEC/EN 61000-6-2, 61000-6-4 |

| Safety Certifications | UL, CE, CSA |

| Dimensions (W × H × D) | 220 × 130 × 35 mm |

| Weight | 0.299 kg |

Product Applications

-

Turbine Temperature Monitoring: Captures accurate RTD signals for gas, steam, and hydro turbine temperature control.

-

Generator Protection Systems: Monitors winding and bearing temperatures to prevent overheating.

-

Industrial Process Control: Provides precise temperature input for critical process monitoring and automation.

-

Oil & Gas Facilities: Measures pipeline, compressor, and equipment temperatures in hazardous environments.

-

Power Plants: Supports thermal protection of turbines, boilers, and auxiliary systems.

-

Chemical and Petrochemical Plants: Ensures process safety by monitoring temperature-sensitive reactions.

-

Manufacturing Lines: Provides input for thermal regulation in production equipment and machinery.

Product Advantages

-

High Accuracy: Designed for precise RTD signal acquisition with minimal noise interference.

-

Multiple Wiring Options: Supports 2-wire, 3-wire, and 4-wire RTD configurations for flexible installation.

-

Compact Form Factor: Space-saving design allows deployment in restricted panel areas.

-

Strong Isolation: Provides channel-to-channel and channel-to-system isolation for signal integrity.

-

Seamless Integration: Fully compatible with GE Mark VI turbine control systems.

-

Robust Construction: Built to withstand industrial temperature, vibration, and humidity extremes.

-

Diagnostic Capability: Channel fault monitoring enhances system reliability and troubleshooting efficiency.

-

Noise Immunity: Superior noise rejection ensures stable and accurate readings in harsh environments.

FAQ

-

How many RTD input channels does the IS200SRTDH2A support?

It supports up to 12 RTD input channels. -

What types of RTD wiring configurations are compatible?

The board supports 2-wire, 3-wire, and 4-wire RTD configurations. -

What is the supported temperature measurement range?

The board can handle -200°C to +850°C depending on the connected RTD sensor. -

Does the board provide signal isolation between channels?

Yes, it offers channel-to-channel and channel-to-system isolation. -

What kind of noise suppression does the IS200SRTDH2A include?

It is designed with high common-mode and differential-mode noise rejection. -

Is the module compatible with redundant GE Mark VI architectures?

Yes, it integrates seamlessly into both simplex and redundant configurations. -

How is the field wire connected to the circuit board?

It uses screw terminal connections to ensure safe and secure wiring. -

Does the IS200SRTDH2A have diagnostic capabilities?

Yes, it can monitor channel status and faults to enhance troubleshooting capabilities. -

How much excitation current does the board provide to the RTD?

It has programmable excitation current optimized for RTD linearity. -

Can this board be used in high vibration environments?

Yes, it is designed for industrial and turbine applications with high mechanical stress.

Recommended related models (same series or with equivalent functions)

| model | describe | Main Features |

|---|---|---|

| IS200SRTDH1A | Standard RTD terminal strip | 12 RTD inputs, full size version |

| IS200SRTDH3A | High Density RTD Terminal Blocks | 24-channel RTD interface for Mark VI |

| IS200THDRH1A | Thermocouple input board | 24-channel thermocouple input module |

| IS200STURH1A | Simplex Turbine Relay Board | Turbine control and relay interface |

| IS200VRTDH1A | Vibration/RTD Combination Input Board | Combined vibration and RTD input channels |

| IS200TRLYH2A | Relay output terminal board | Relay output interface for Mark VI system |

Recommended popular GE models

| model | describe | Main Applications |

|---|---|---|

| IS200DSPXH1A | Digital signal processor control board | Core turbo control processing |

| IS200VPRCH1B | Voltage stabilized power supply board | Generator excitation and voltage regulation |

| IS200STCIH6A | Contact input terminal board | 32-channel digital input interface |

| IS200TRLYH1B | Trip relay output terminal board | High-speed trip relay action |

| IS200EROIH1A | Emergency relay output board | Redundant relay outputs for safety systems |

| IS200TREGH2A | Trip emergency relay output board | Critical turbine and process safety controls |

Excellent PLC

Excellent PLC