| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

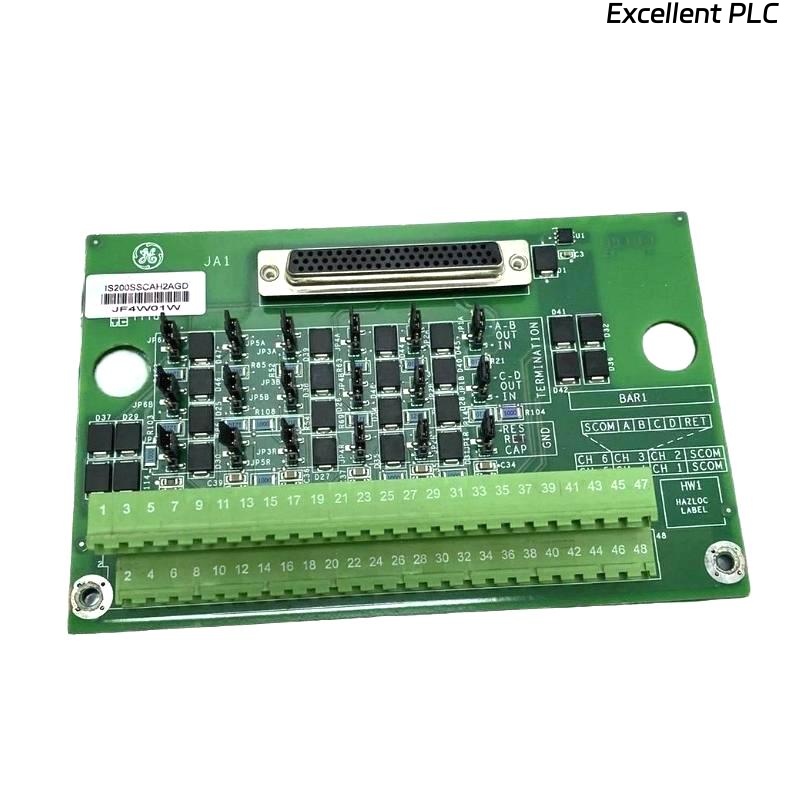

The GE IS200SSCAH1A Serial Communication I/O Terminal Board is a high-performance interface module designed for GE Mark VI and Mark VIe control systems. It provides reliable connectivity between communication networks and I/O modules, facilitating efficient data transfer, signal conditioning, and system monitoring. Engineered for industrial and power generation environments, the board ensures stable signal integrity, robust electrical isolation, and seamless integration with GE’s proprietary communication protocols, enabling fast, accurate, and secure exchange of process and turbine data.

Product Specifications

| Parameter | Description |

|---|---|

| Model | GE IS200SSCAH1A Serial Communication I/O Terminal Board |

| Primary Function | Interfaces communication networks with I/O modules for signal transfer |

| Input Voltage | 24 V DC nominal (18–30 V DC operating range) |

| Power Consumption | <10 W typical |

| Number of Channels | Up to 16 I/O channels |

| Communication Interface | High-speed serial differential signals compatible with GE Mark VI/VIe systems |

| Isolation Voltage | 2500 V RMS between communication lines and local logic |

| Operating Temperature | –20 °C to +65 °C |

| Cooling Method | Natural convection (forced-air optional) |

| Dimensions | 260 × 120 × 35 mm |

| Weight | 0.78 kg |

| Compliance | CE, UL, and RoHS |

| Protection Features | ESD suppression, over-voltage protection, and hot-swap capability |

Applications

-

Turbine and Generator Control – Ensures accurate data exchange between controllers and I/O devices.

-

Industrial Process Automation – Interfaces remote I/O modules for chemical, petrochemical, and manufacturing plants.

-

Redundant Communication Systems – Supports dual-path topologies to maintain operational reliability.

-

System Upgrades and Retrofits – Facilitates replacement or integration of new modules in existing Mark VI/VIe networks.

-

Real-Time Monitoring – Enables fast acquisition and transfer of process parameters for safety and optimization.

Advantages

-

Reliable Data Transfer – High-speed differential communication minimizes errors and signal degradation.

-

Robust Electrical Isolation – 2500 V RMS isolation prevents ground loops and protects controller electronics.

-

Flexible Integration – Compatible with Mark VI and Mark VIe platforms for new installations or system upgrades.

-

Hot-Swap Capability – Allows maintenance without interrupting system operation.

-

Low Power Consumption – Efficient design reduces heat generation and energy usage.

-

Noise Immunity – Shielded inputs and robust signal conditioning reduce EMI/RFI impact in industrial environments.

-

Compact and Modular – Standard GE rack-mount dimensions simplify installation and replacement.

FAQ

-

What is the main function of the IS200SSCAH1A board?

It connects communication networks to I/O modules, ensuring accurate and reliable data transfer in GE Mark VI/VIe systems. -

How many I/O channels can it support?

The board supports up to 16 channels, allowing multiple signals to be routed through a single module. -

What communication interface is used?

It uses high-speed serial differential signals compatible with GE Mark VI/VIe control protocols. -

Is galvanic isolation provided?

Yes, 2500 V RMS isolation protects the local logic from voltage surges and ground loops. -

Can the board be hot-swapped?

Yes, it can be installed or removed without powering down the system, facilitating maintenance. -

What input voltage range does it support?

The board operates on a 24 V DC nominal supply, with an operating range of 18–30 V DC. -

How does it handle ESD and over-voltage conditions?

Integrated ESD suppressors and over-voltage protection circuits safeguard both the board and connected devices. -

Is the board compatible with redundant communication topologies?

Yes, it supports dual-path or redundant network configurations to maintain continuous operation. -

What is the recommended cooling method?

Natural convection is sufficient under normal conditions, but forced-air cooling may be used in high-density installations. -

How is the board integrated into existing Mark VI/VIe systems?

It mounts in standard GE racks and interfaces directly with the system bus and I/O modules, requiring no special adapters.

Recommended Related Models (Same Series)

| Model | Description |

|---|---|

| IS200IGPAG2A | Gate Drive Power Supply Board |

| IS200EPSMG2RED | Exciter Power Supply Module |

| IS200EXCSG1A | Exciter Conduction Sensor Board |

| IS200EBKPG1A | Exciter Backplane Board |

| IS200PDOAH1B | Turbine Protection Board |

| IS200ISBEH1A | ISBus Extender Board |

Popular GE Models (Same Brand)

| Model | Description |

|---|---|

| IS200ICIAH1ABB | Innovation I/O Board |

| IS200AECPH1CCB | Mark VI Series Control Board |

| IS200PRTDH1A | RTD Terminal Board |

| IS200RCSBG1B | RC Snubber Board |

| IS200ISBH1A | ISBus Hub Board |

| IS200IGPAG2B | Gate Drive Power Supply (Enhanced) |

Excellent PLC

Excellent PLC