| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

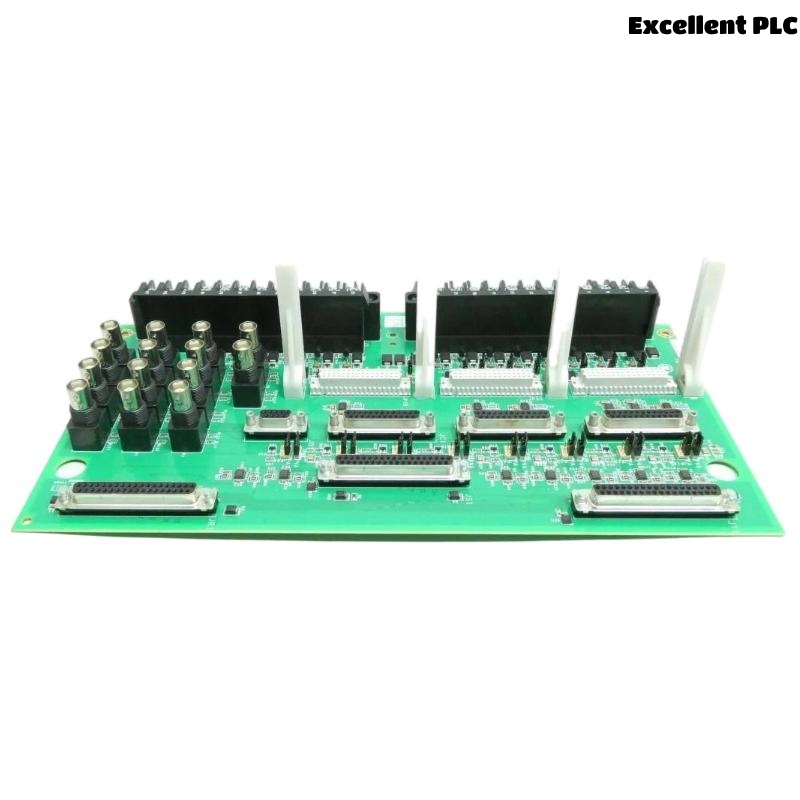

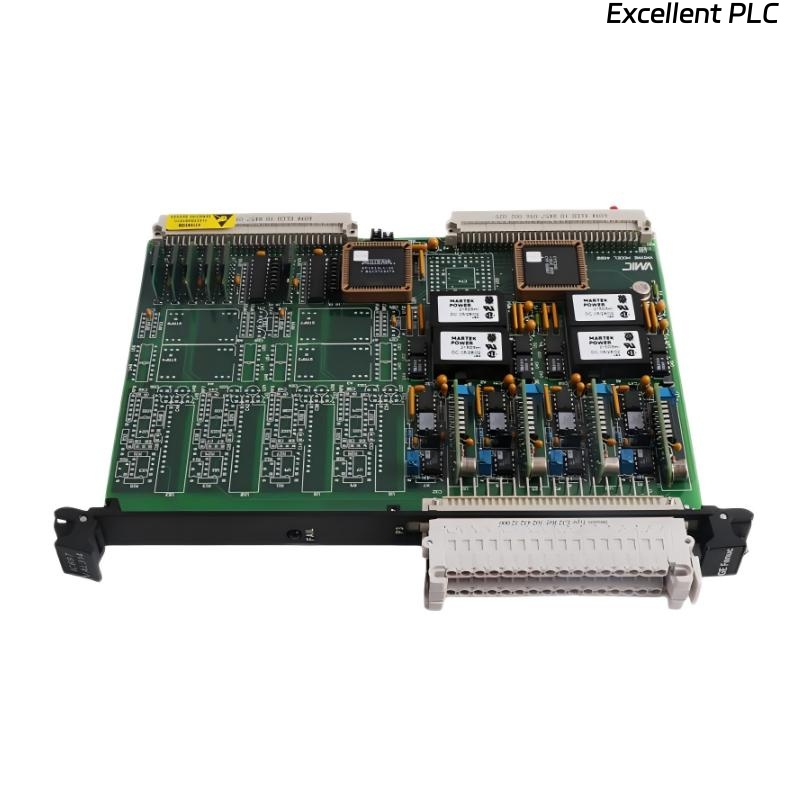

GE’s IS200TVBAH2A vibration input terminal board is a high-performance interface module designed for precise vibration signal acquisition in turbine and rotating machinery monitoring systems. It serves as a termination point for multiple vibration sensors, conditioning and routing the signals to the Mark VIe control system or related monitoring hardware. Designed for industrial-grade reliability, the IS200TVBAH2A is suitable for harsh environments such as power generation, oil and gas, and heavy manufacturing.

The board supports a variety of sensor types, including accelerometers, velocity probes, and displacement sensors, ensuring accurate data acquisition for predictive maintenance and machine protection applications. Its robust PCB design and optimized grounding minimize noise and interference, providing clear and reliable vibration data critical for machinery health monitoring.

Product Specifications

| scope | describe |

|---|---|

| model | IS200TVBAH2A |

| Manufacturer | General Electric (GE) |

| Function | Vibration input terminal board |

| Supported input | Accelerometers, velocity probes, displacement probes |

| Input Channel | Multi-channel (typically 8-12 inputs) |

| Signal Type | Simulated vibration signal |

| interface | Terminal-based sensor wiring |

| Grounding | Isolation and shielding of signal ground |

| Operating voltage | Low-level signal conditioning |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Compliance | CE, UL, RoHS |

| Dimensions | 250 x 150 x 50 mm |

| Weight | 0.8 kg |

Product Applications

-

Turbine Vibration Monitoring: Integrates with GE Mark VIe control systems for real-time turbine health analysis.

-

Rotating Machinery Protection: Provides accurate vibration input data to protect pumps, compressors, and motors.

-

Condition-Based Maintenance: Enables predictive maintenance strategies by providing detailed vibration profiles.

-

Industrial Automation Systems: Supports machinery diagnostics in power plants, refineries, and manufacturing facilities.

-

Data Acquisition Systems: Used as part of advanced monitoring systems to ensure machinery performance and safety.

-

Oil & Gas Applications: Suitable for upstream and downstream vibration monitoring in harsh operating environments.

Product Advantages

-

High Signal Integrity: Optimized PCB layout and grounding reduce electrical noise and improve signal clarity.

-

Multi-Sensor Support: Handles a wide range of vibration sensors for flexible system integration.

-

Seamless Integration: Designed to work natively with GE Mark VIe and compatible monitoring systems.

-

Industrial Reliability: Built for continuous operation in high-vibration and high-temperature environments.

-

Compact Design: Space-efficient board suitable for panel or rack-mounted installations.

-

Enhanced Machine Protection: Provides precise input data for advanced machinery diagnostics and safety systems.

FAQ

-

What types of vibration sensors are supported by the IS200TVBAH2A?

The board supports accelerometers, velocity probes, and displacement probes for comprehensive vibration monitoring. -

Does the board provide isolated grounding for vibration signal inputs?

Yes, the IS200TVBAH2A uses isolated and shielded signal grounds to minimize noise and interference. -

Can this board interface directly with the GE Mark VIe control system?

Yes, it is designed for direct integration with the Mark VIe platform for real-time vibration data acquisition. -

How many vibration input channels are available on the IS200TVBAH2A?

The board typically supports multiple channels (commonly 8–12) for connecting various vibration sensors simultaneously. -

Is the IS200TVBAH2A suitable for high-frequency vibration analysis?

Yes, it is designed to handle a wide frequency range, making it suitable for both low- and high-frequency vibration monitoring. -

Does the board provide any built-in signal conditioning for the vibration input?

The board provides basic filtering and routing to ensure a clean analog signal is transmitted to the monitoring system. -

Can the IS200TVBAH2A operate in high temperature industrial environments?

Yes, it is rated for operation from 0°C to +60°C and storage down to -40°C. -

Is this board compatible with non-GE vibration monitoring systems?

While it is optimized for GE systems, it can be used with other monitoring platforms if properly interfaced. -

How does a circuit board minimize electromagnetic interference in a noisy environment?

It uses shielded traces, proper grounding schemes, and EMI-resistant design to maintain signal integrity. -

Can this board be used in critical machinery protection applications?

Yes, it is designed to provide reliable input data for machinery safety and protection systems.

Related models (same series)

| model | describe |

|---|---|

| IS200TVBAH1A | Vibration input terminal board |

| IS200TVBH1A | Vibration monitoring terminal board |

| IS200TBTCH1C | Vibration/Temperature Input Board |

| IS200TTURH1B | Steam turbine vibration terminal board |

| IS200TBTCH2A | Vibration and temperature combination plate |

| IS200TBQCH1A | Multi-sensor input terminal board |

Popular GE Models (Same Brand)

| model | describe |

|---|---|

| IS200STCIH2A | Simplex contact input terminal board |

| IS200TRLYH1B | Relay output terminal board |

| IS200EPDMG1B | Exciter power distribution module |

| IS200VVIBH1C | Vibration monitoring board |

| IS200TREGH1B | Turbine governor terminal block |

| IS200VAICH1C | Analog input terminal board |

Excellent PLC

Excellent PLC