| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

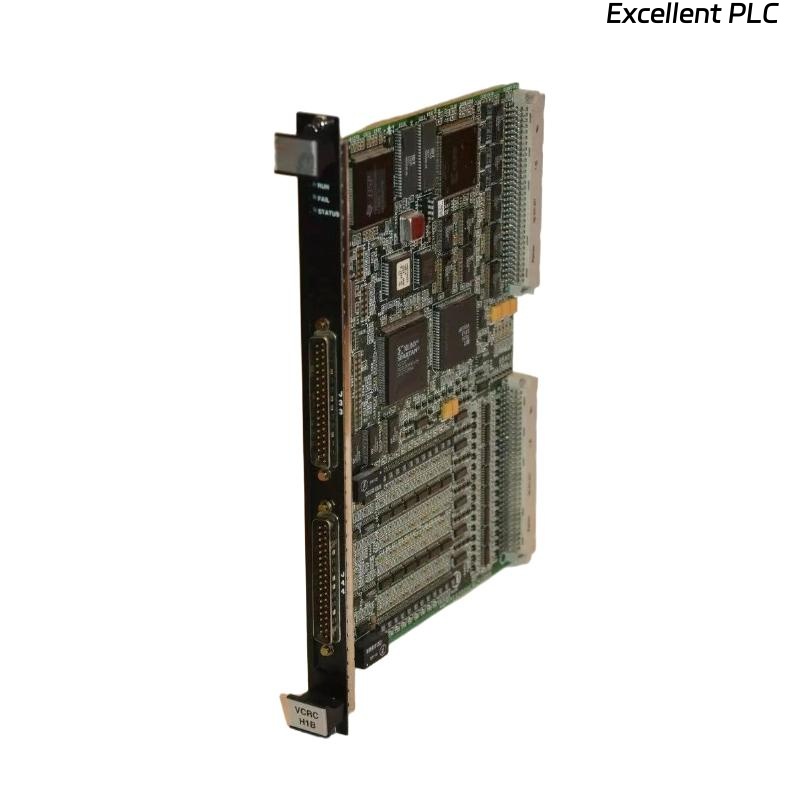

The GE IS200VROCH1BBR Control Board is a high-performance module designed for the GE Mark VIe distributed control system. It functions as a vital interface between turbine control logic and field devices, managing real-time operations, executing control algorithms, and ensuring reliable communication with other system components. Engineered with robust isolation, noise immunity, and extended temperature tolerance, the IS200VROCH1BBR is well-suited for demanding industrial environments such as gas, steam, and combined-cycle power plants. Its architecture supports deterministic control cycles, redundant system topologies, and continuous monitoring for critical process applications.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS200VROCH1BBR |

| Series | GE Mark VIe Control System |

| Primary Function | High-speed control and real-time I/O processing |

| Power Supply | 24 V DC nominal (18–30 V DC operating range) |

| Processor | High-speed 32-bit embedded microcontroller |

| I/O Channels | Multiple isolated digital and analog interfaces |

| Communication Protocols | Ethernet, RS-485, proprietary Mark VIe backplane bus |

| Isolation Voltage | 2500 V AC minimum between logic and field circuits |

| Operating Temperature | –40 °C to +70 °C |

| Humidity | 0–95 % non-condensing |

| Vibration Resistance | 5 g, 10–2000 Hz |

| Shock Resistance | 30 g, 11 ms half-sine |

| Firmware Support | Mark VIe standard and redundant configurations |

| Dimensions (W×H×D) | 230 × 110 × 40 mm |

| Weight | 1.15 kg |

| Mounting | Rack-mounted or panel-mounted with secure locking connectors |

| Board Material | FR4 PCB with conformal protective coating |

Applications

The IS200VROCH1BBR is widely deployed in:

-

Gas and steam turbine control systems requiring high-speed response

-

Power plant distributed control systems (DCS) and balance-of-plant operations

-

Real-time process automation in petrochemical and industrial facilities

-

Redundant control networks where deterministic data exchange is critical

-

Integration with GE Mark VIe controllers for generator protection and load-shedding logic

Advantages

-

Deterministic Performance: Guarantees consistent real-time control cycles under heavy loads.

-

Robust Isolation: High isolation voltage prevents cross-channel interference and protects sensitive electronics.

-

Flexible Communication: Supports Ethernet and RS-485 as well as native Mark VIe backplane communication.

-

Industrial Durability: Rated for extreme temperatures, vibration, and electrical noise common in turbine halls.

-

Redundant Operation: Fully compatible with dual and triple-modular-redundancy Mark VIe topologies.

-

Ease of Maintenance: Modular design with clearly labeled connectors and built-in diagnostics simplifies service.

Frequently Asked Questions (FAQ)

-

Which control algorithms can be implemented on the IS200VROCH1BBR?

It supports GE Mark VIe standard control blocks and user-defined algorithms within the system’s software environment. -

How does the board ensure deterministic communication over Ethernet?

It employs time-synchronized protocols and priority scheduling to maintain real-time data exchange. -

Is hot-swapping supported for maintenance?

Yes, when used in a redundant Mark VIe rack, the board can be hot-swapped with minimal disruption. -

What protections exist against electrical noise and surges?

The board includes galvanic isolation, surge suppressors, and EMI/RFI filtering on all I/O channels. -

Can it interface directly with third-party PLCs?

Yes, via standard Modbus/TCP or RS-485 serial connections configured through Mark VIe tools. -

How is firmware updated in the field?

Firmware can be updated through the Mark VIe system maintenance utility via the backplane or Ethernet port. -

What is the typical control loop scan time achievable?

Less than 5 ms under full I/O load, depending on system configuration. -

Does the board support redundant power feeds?

Yes, it accepts dual 24 V DC feeds for uninterrupted operation. -

How are diagnostic alerts communicated to operators?

Through integrated LED indicators and system alarms transmitted to the Mark VIe HMI. -

Can it be integrated into existing Mark VI systems?

Yes, with proper firmware and configuration, it can operate alongside legacy Mark VI equipment.

Related Models – Same Series or Function

| Model | Description |

|---|---|

| IS200VCRCH1B | VME communication controller for Mark VIe |

| IS200VTCCH1C | Temperature control board with high-speed analog inputs |

| IS200VVIBH1C | Vibration monitoring and protection interface |

| IS200VPRCH1B | Power regulator control module for Mark VIe systems |

| IS200VSVOH1B | Servo control output board for precision actuator control |

| IS200VAICH1D | High-accuracy analog input module |

Popular GE Mark VIe Models

| Model | Description |

|---|---|

| IS200DSPXH1D | Digital signal processor control board |

| IS200STCIH6A | Simplex contact input terminal board |

| IS200EXHSG4A | Exciter high-speed relay driver board |

| IS200TRLYH1B | Relay output terminal board for protective relays |

| IS200TPROH1B | Turbine protection relay output board |

| IS200TRPGH2B | Primary trip terminal board with redundant trip channels |

Excellent PLC

Excellent PLC