| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

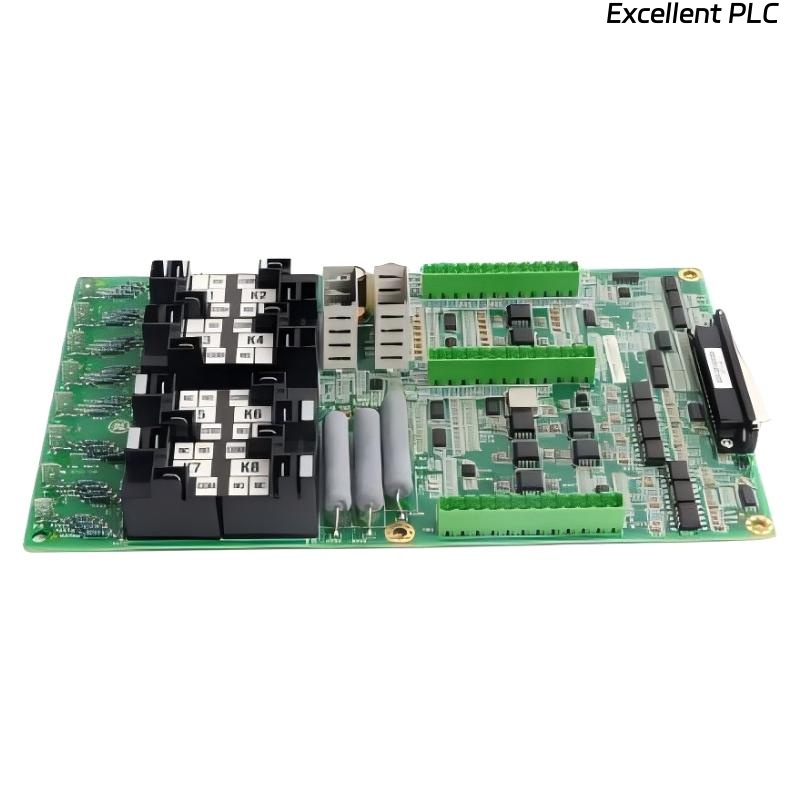

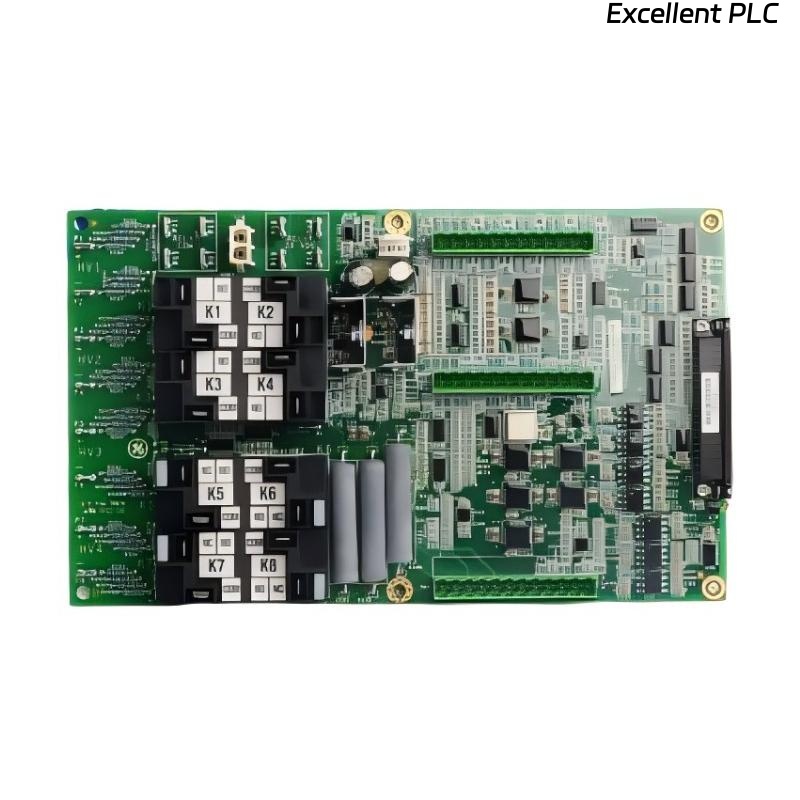

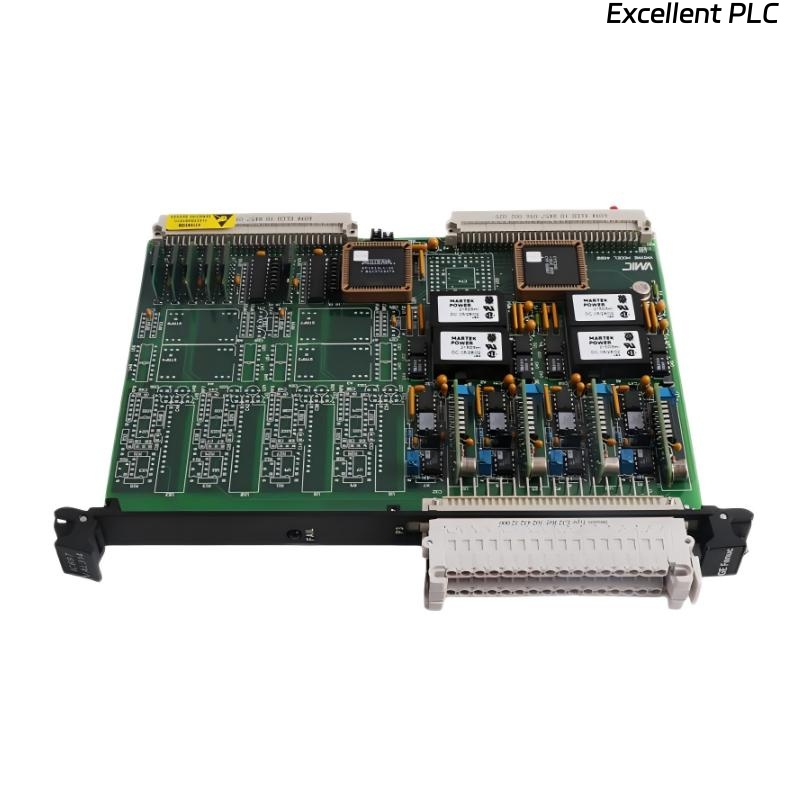

The GE IS210AEAAH1B Conformal Coated Printed Circuit Board is a high-performance industrial-grade control module designed for use in GE Mark VI and EX2100 control systems. This board plays a crucial role in signal processing, communication, and system interface functions within turbine control and automation environments. Its conformal coating provides an extra layer of protection against harsh environmental conditions such as humidity, dust, chemical exposure, and temperature variations, ensuring long-term operational stability and reliability.

Manufactured using advanced multilayer PCB technology, the IS210AEAAH1B ensures efficient electrical performance, reduced electromagnetic interference, and consistent signal integrity. The board is precision-engineered to integrate seamlessly with GE’s modular control system architecture, making it suitable for high-reliability power generation and industrial automation applications.

Technical Specifications

| Parameter | Description |

|---|---|

| Manufacturer | General Electric (GE) |

| Product Model | IS210AEAAH1B |

| Product Type | Conformal Coated Printed Circuit Board |

| Series | Mark VI / EX2100 Control System |

| Coating Type | Acrylic conformal coating for moisture and corrosion protection |

| System Compatibility | GE Mark VI and EX2100 control platforms |

| Function | Analog and digital signal acquisition, conditioning, and processing |

| Power Supply Requirement | +5 VDC, ±15 VDC from rack power bus |

| Input/Output Interface | Multi-pin backplane connector and field terminal connectors |

| Communication Bus | VME or backplane interface for real-time data exchange |

| Signal Channels | Multiple analog and digital signal lines depending on configuration |

| Operating Voltage Range | ±5%, stable under industrial conditions |

| Isolation Voltage | 1000 VDC between logic and signal ground |

| Protection Features | ESD protection, transient suppression, and reverse polarity protection |

| Diagnostics | Self-test and onboard LED status indicators |

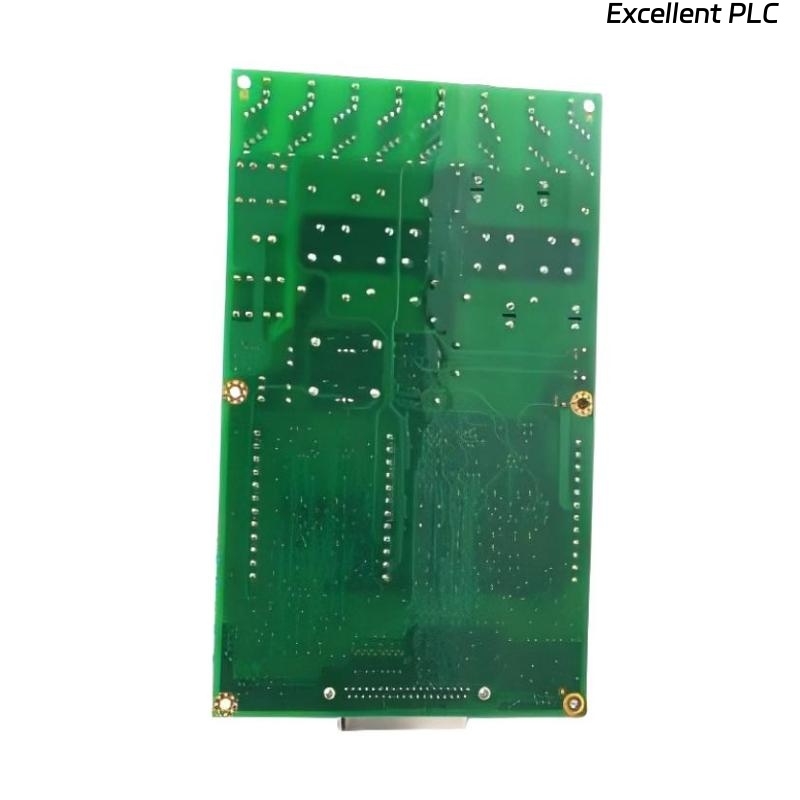

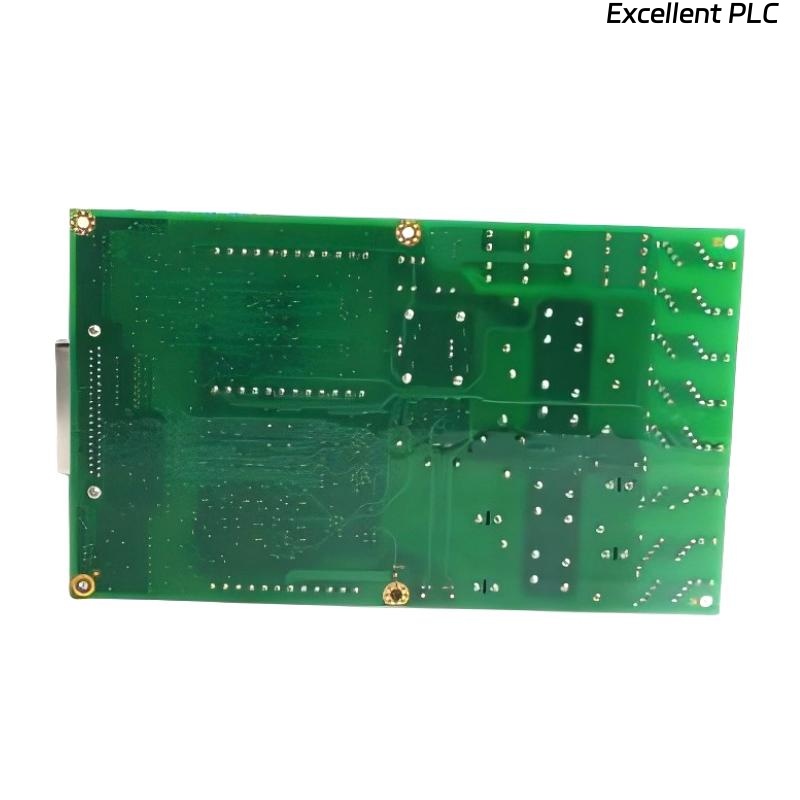

| PCB Material | High-density FR4 epoxy laminate, multilayer design |

| Conformal Coating Standard | MIL-I-46058C and IPC-CC-830 compliant |

| Operating Temperature | -30°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5%–95%, non-condensing |

| Mounting Type | Rack-mounted, plug-in type |

| Compliance | CE, UL, RoHS, ISO9001 certified |

| Dimensions | 200 × 180 × 25 mm |

| Weight | 0.9 kg |

Product Applications

The GE IS210AEAAH1B conformal coated PCB is utilized in a wide range of industrial control systems where precision, reliability, and protection against environmental stress are essential. It serves as a core component in GE’s Mark VI turbine control systems, managing both analog and digital data signals for real-time control and monitoring.

Primary applications include:

-

Gas and Steam Turbine Control Systems – Processes analog sensor signals and transmits data to control processors for turbine regulation.

-

Power Generation Plants – Acts as an interface between field instrumentation and the central control unit.

-

Process Automation Systems – Supports analog signal conditioning, filtering, and control logic in distributed control environments.

-

Industrial Drives and Motor Control – Provides signal processing for speed and torque control circuits.

-

Marine and Offshore Equipment – Delivers robust performance in high-humidity and vibration-prone maritime systems.

-

Oil and Gas Facilities – Ensures stable and interference-free signal transmission in hazardous locations.

The conformal coating makes the board especially suitable for installations exposed to corrosive or high-moisture conditions, offering a longer service life and improved system dependability.

Product Advantages

-

Enhanced Environmental Protection: The conformal coating provides resistance to moisture, chemicals, dust, and corrosion, extending the lifespan of the board.

-

High Signal Integrity: Advanced multilayer PCB structure minimizes signal noise and cross-talk for accurate data processing.

-

Reliable Performance: Stable operation across wide temperature ranges ensures system uptime in demanding environments.

-

Comprehensive Circuit Protection: Built-in ESD, surge, and reverse polarity protection enhances electrical durability.

-

Compatibility: Designed for seamless integration with GE Mark VI and EX2100 control racks.

-

Simplified Maintenance: Conformal coating improves durability without obstructing diagnostic access or maintenance procedures.

-

Low Power Consumption: Optimized circuit design reduces energy usage while maintaining signal precision.

-

Rugged Industrial Design: Withstands vibration, electrical noise, and harsh field conditions typical in power generation sites.

-

Integrated Diagnostics: Onboard LEDs and self-check routines simplify troubleshooting and system verification.

-

Global Standard Compliance: Manufactured under strict quality control to meet industrial and environmental standards.

FAQ

-

What is the primary role of the GE IS210AEAAH1B board?

It functions as a signal processing and interface module for GE Mark VI and EX2100 turbine control systems. -

What type of protective coating is used on this board?

The board uses an acrylic-based conformal coating that meets MIL-I-46058C and IPC-CC-830 standards. -

Does the conformal coating affect heat dissipation?

No, the coating is thin and thermally stable, maintaining efficient heat transfer from the components. -

What voltages does the IS210AEAAH1B require for operation?

It operates with +5 VDC and ±15 VDC power supplies provided through the rack power bus. -

How does the board communicate with other control modules?

It interfaces through a VME or proprietary GE backplane bus, allowing synchronized data exchange. -

What diagnostic features are included on this board?

It includes onboard LEDs and built-in self-test functions to identify signal and communication faults. -

Is this board interchangeable with non-conformal coated versions?

Functionally, yes; however, the conformal coated version provides better environmental protection and should be used in harsher conditions. -

Can the IS210AEAAH1B handle both analog and digital signals?

Yes, it supports mixed-signal processing for a combination of analog sensor inputs and digital control signals. -

What protection measures are implemented for signal integrity?

The board features transient suppression, EMI filtering, and isolated ground paths to maintain clean signal transmission. -

How does the board perform under high humidity or dust exposure?

Its conformal coating prevents moisture penetration and contamination, ensuring continued reliable operation.

Related or Equivalent Models (Same Series)

| Model Number | Description | Key Feature |

|---|---|---|

| IS210AEAAH1A | Printed Circuit Board | Standard uncoated version |

| IS210AEABH1B | Conformal Coated Board | Enhanced analog input handling |

| IS210AEADH1B | Control Interface Board | Integrates analog/digital control channels |

| IS210AEAHH1A | High-Speed Communication Board | Improved data throughput |

| IS210AEAGH1B | Input/Output Processing Board | Supports additional I/O channels |

| IS210AEAFH1B | Feedback Interface Module | Handles sensor and feedback loops |

Popular GE Models (Same Brand)

| Model Number | Product Type | Main Function |

|---|---|---|

| IS200DSPXH1D | Digital Signal Processor Board | Real-time data computation and turbine control |

| IS200VVIBH1C | Vibration Monitoring Module | Measures and processes turbine vibration data |

| IS200STCIH2A | Contact Input Terminal Board | Acquires and filters digital input signals |

| IS200TRLYH1B | Relay Output Board | Controls switching and relay actuation |

| IS200SRLYH3A | System Relay Module | Provides controlled relay interfacing |

| IS200TBCIH1BDC | Terminal Board | Connects field devices to the control system |

Excellent PLC

Excellent PLC