| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

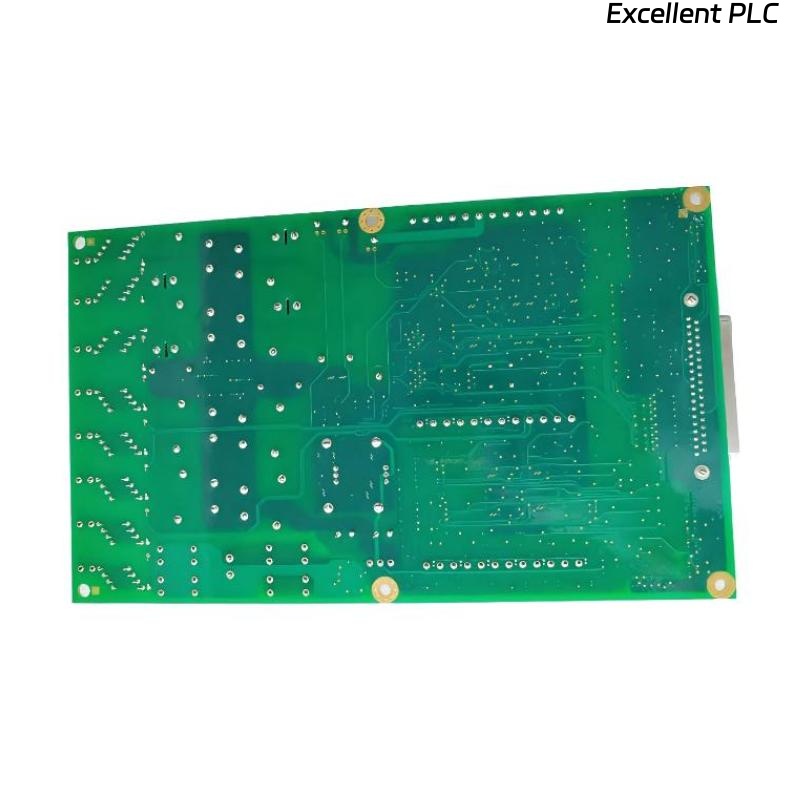

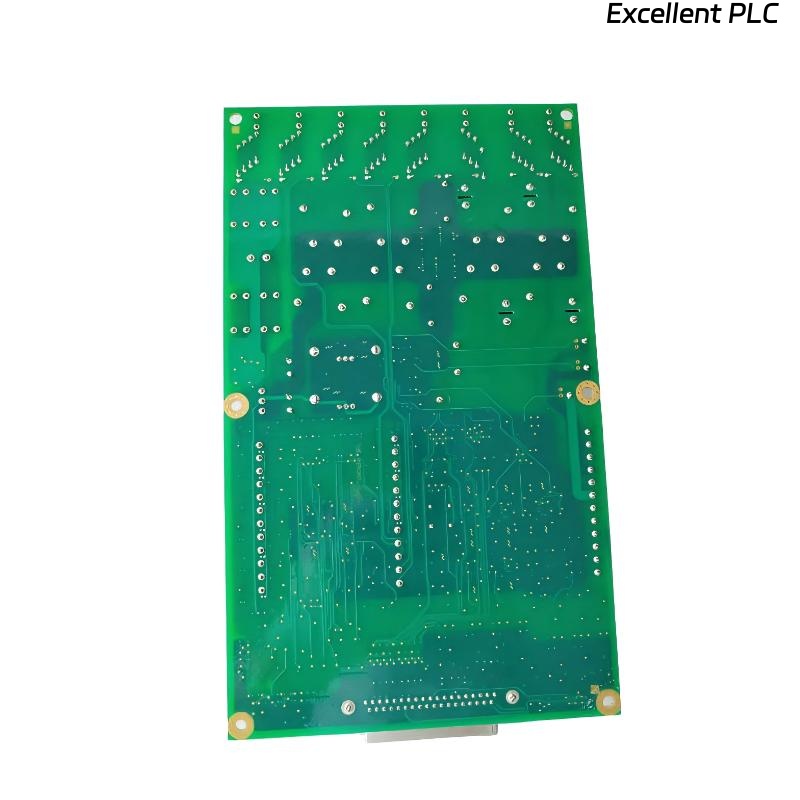

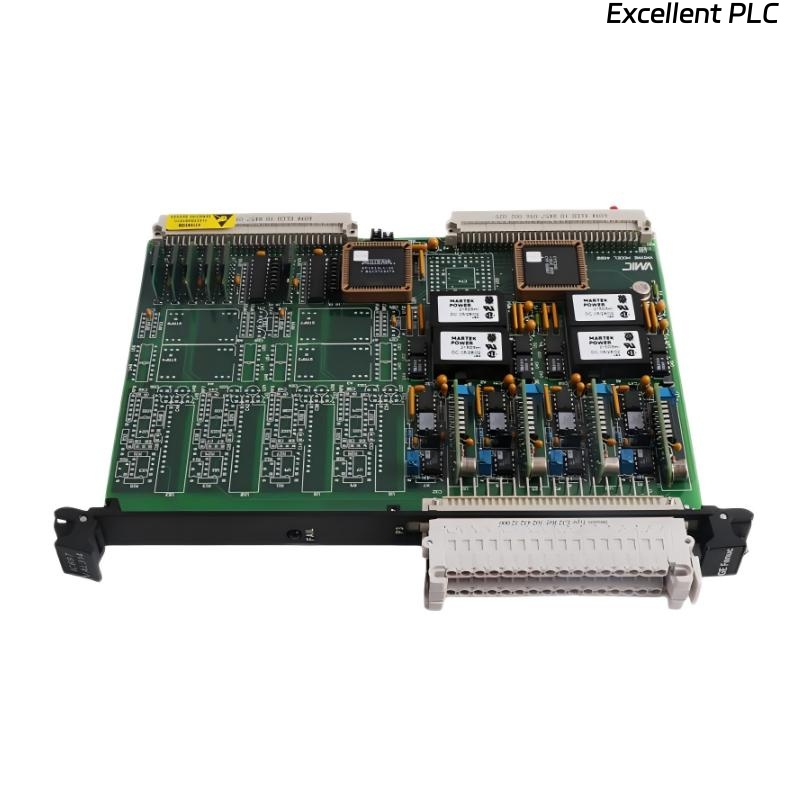

The GE IS210AEAAH2B Conformal Coated Printed Circuit Board is a high-reliability industrial-grade circuit board designed for GE Mark VI and EX2100 control systems. It serves as a critical component within turbine control and process automation systems, managing analog and digital signal processing, conditioning, and communication between various control modules.

This board is built with a conformal coating, offering superior resistance to humidity, dust, chemicals, and other environmental contaminants. The protective coating ensures electrical insulation, corrosion resistance, and long-term operational stability even under severe industrial or outdoor conditions.

Manufactured using multilayer FR4 epoxy laminate, the IS210AEAAH2B provides excellent signal integrity, low noise, and enhanced electromagnetic compatibility (EMC). It is widely utilized in power generation, oil and gas, marine, and process automation industries, where reliability and precision signal handling are essential.

Technical Specifications

| Parameter | Description |

|---|---|

| Manufacturer | General Electric (GE) |

| Product Model | IS210AEAAH2B |

| Product Type | Conformal Coated Printed Circuit Board |

| System Compatibility | GE Mark VI / EX2100 Control Systems |

| Functional Role | Analog and digital signal acquisition, conditioning, and communication |

| Coating Type | Acrylic conformal coating (meets MIL-I-46058C / IPC-CC-830 standards) |

| Power Supply Requirement | +5 VDC and ±15 VDC via rack backplane bus |

| Signal Channels | Multiple analog and digital I/O paths (varies by configuration) |

| Communication Interface | VME or proprietary backplane communication bus |

| Input Voltage Tolerance | ±5% from nominal supply |

| Isolation Voltage | 1000 VDC between signal and logic ground |

| Protection Features | ESD protection, surge suppression, reverse polarity protection |

| Diagnostics | Onboard LED indicators and self-test capabilities |

| PCB Material | High-density FR4 multilayer epoxy resin |

| Conformal Coating Standard | MIL-I-46058C / IPC-CC-830 compliant acrylic film |

| EMI/EMC Compliance | Meets IEC 61000 standards for industrial noise immunity |

| Operating Temperature | -30°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5%–95%, non-condensing |

| Mounting Method | Rack-mounted plug-in module |

| Compliance Standards | CE, UL, RoHS, ISO9001 certified |

| Dimensions | 200 × 180 × 25 mm |

| Weight | 0.95 kg |

Product Applications

The GE IS210AEAAH2B board is designed for environments that require precise signal processing and high system reliability. Its robust electrical and environmental characteristics make it an essential component in industrial control infrastructures.

Typical applications include:

-

Gas and Steam Turbine Control Systems – Interfaces with turbine sensors, transducers, and actuators for closed-loop control.

-

Power Generation Facilities – Serves as an analog/digital interface board for data acquisition and control in GE Mark VI systems.

-

Process Automation Systems – Manages data communication between field devices and distributed control systems.

-

Industrial Motor and Drive Control – Provides reliable analog signal conditioning and feedback loop management.

-

Oil and Gas Platforms – Designed to withstand moisture and corrosive atmospheres common in offshore facilities.

-

Marine Power and Propulsion Systems – Ensures accurate signal integrity and protection from marine humidity and vibration.

The conformal coating allows this board to perform reliably in harsh, high-moisture, and electrically noisy environments, making it ideal for mission-critical control operations.

Product Advantages

-

Superior Environmental Protection: The conformal coating guards against moisture, salt spray, chemical vapors, and dust accumulation.

-

High Signal Integrity: Multilayer PCB construction minimizes crosstalk and electrical noise interference.

-

Enhanced Electrical Protection: Features comprehensive ESD, surge, and reverse polarity protection circuits.

-

Reliable Communication: Designed for seamless backplane integration within Mark VI and EX2100 systems.

-

Thermal Stability: Maintains stable performance under extreme temperature variations and continuous operation.

-

Rugged Industrial Design: Resistant to mechanical shock, vibration, and industrial electromagnetic interference.

-

Simplified Diagnostics: Built-in LED indicators enable quick fault detection and maintenance.

-

Long-Term Durability: Protective coating significantly extends the service life of components and solder joints.

-

High Compatibility: Directly interchangeable with other AEAA series modules without system reconfiguration.

-

Quality Assurance: Manufactured and tested under GE’s stringent industrial standards for reliability and consistency.

FAQ

-

What is the main function of the GE IS210AEAAH2B board?

It processes and transmits analog and digital signals within GE Mark VI and EX2100 control systems. -

What kind of conformal coating is used on this board?

It uses an acrylic-based conformal coating compliant with MIL-I-46058C and IPC-CC-830 standards. -

How does the coating improve the board’s reliability?

It protects against humidity, dust, corrosion, and chemical contamination, extending operational life. -

Which voltages power the IS210AEAAH2B?

The board requires +5 VDC and ±15 VDC supplied through the rack backplane. -

Does this board support both analog and digital signal processing?

Yes, it is capable of handling mixed analog and digital signals for data acquisition and control tasks. -

What communication interface does it use?

It uses a VME or GE proprietary backplane bus for real-time data communication. -

How is diagnostic information displayed?

Onboard LEDs indicate the board’s operational status and fault conditions for quick troubleshooting. -

What kind of protection circuits are built into this board?

It includes over-voltage, ESD, and transient surge suppression for signal and logic circuits. -

Is the board hot-swappable within the rack system?

No, it should only be inserted or removed when the system power is off to prevent electrical damage. -

Can the IS210AEAAH2B be replaced with the IS210AEAAH1B model?

Yes, both are functionally compatible, but the H2B version features improved coating and signal conditioning enhancements.

Related or Equivalent Models (Same Series)

| Model Number | Description | Key Feature |

|---|---|---|

| IS210AEAAH1B | Conformal Coated PCB | First-generation version with standard protection |

| IS210AEABH1B | Signal Processing Board | Enhanced analog filtering design |

| IS210AEADH1B | Control Interface Module | Integrates communication and control functions |

| IS210AEAFH1B | Feedback Interface Board | Provides sensor feedback management |

| IS210AEAGH1B | Input/Output Processing PCB | High-channel density design |

| IS210AEAHH1B | Communication Interface Board | Supports high-speed data transfer |

Popular GE Models (Same Brand)

| Model Number | Product Type | Main Function |

|---|---|---|

| IS200DSPXH1D | Digital Signal Processor Board | High-speed processing for turbine control |

| IS200VVIBH1C | Vibration Monitoring Module | Measures and monitors vibration signals |

| IS200TRLYH1B | Relay Output Board | Controls external relays and actuators |

| IS200STCIH2A | Contact Input Terminal Board | Acquires and filters digital input signals |

| IS200SRLYH3A | System Relay Interface Module | Provides system-level relay management |

| IS200TBCIH1BDC | Terminal Board | Connects sensors and field wiring to the control system |

Excellent PLC

Excellent PLC