| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

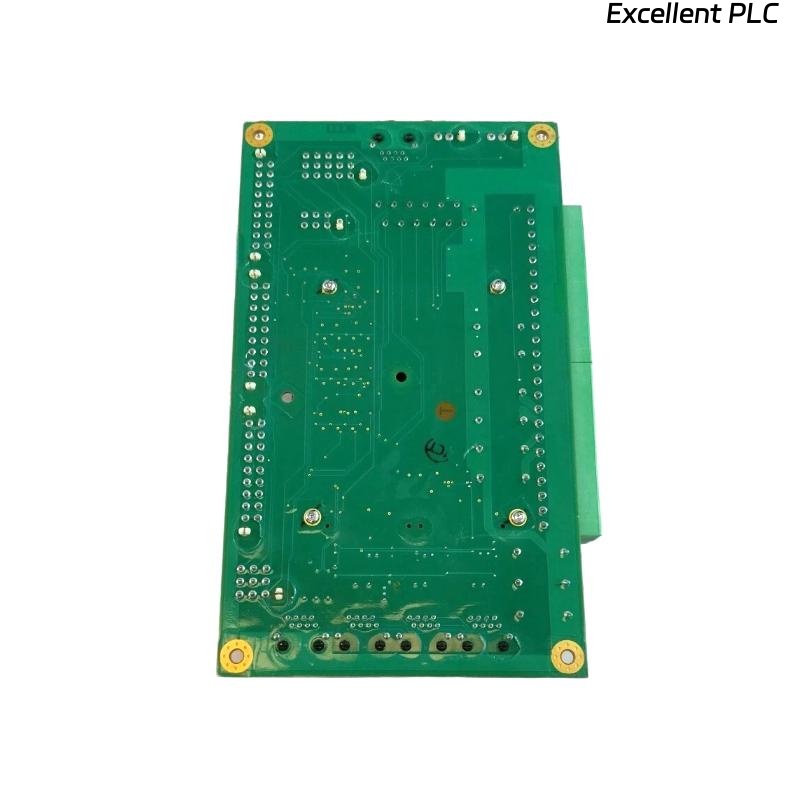

The GE IS210BPPH2BLD Printed Circuit Board (PCB) is a high-reliability control board engineered for GE’s Mark VIe turbine and industrial automation platforms. Designed to serve as a central interface for signal processing and power distribution, this board combines dense multilayer construction with advanced noise-suppression features. It provides stable operation in harsh industrial environments such as gas and steam turbine control rooms, power plants, and critical process facilities. Its robust layout and precision-engineered components ensure accurate data handling and long-term operational stability.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS210BPPH2BLD |

| Product Type | High-density printed circuit control board |

| Function | Signal conditioning, logic interfacing, and power routing |

| Series | GE Mark VIe Control System |

| Input Voltage Range | 24 V DC nominal (18–32 V DC operating window) |

| Output Interfaces | Multiple differential and single-ended I/O channels |

| Clock/Logic Speed | Up to 66 MHz embedded controller bus |

| Operating Temperature | –40 °C to +70 °C |

| Humidity Range | 0–95 % non-condensing |

| Vibration Resistance | Up to 5 g, 10–2000 Hz |

| Shock Resistance | 30 g, 11 ms half-sine |

| PCB Layers | 8-layer FR4 with 2 oz copper and conformal coating |

| Diagnostics | On-board status LEDs and built-in self-test |

| Cooling | Natural convection or forced-air assisted |

| Dimensions (W×H×D) | 240 × 120 × 25 mm |

| Weight | 1.25 kg |

| Mounting | Rack or panel mounting with secure grounding |

| Compliance | RoHS, CE, UL recognized |

Applications

The IS210BPPH2BLD PCB is deployed in numerous industrial sectors:

-

Turbine Control Systems: Core logic interface for Mark VIe gas and steam turbine controllers.

-

Power Generation Plants: Manages I/O data flow and power routing to protection relays and sensors.

-

Industrial Automation: Provides precise signal conditioning for distributed control systems.

-

Oil & Gas Operations: Supports SCADA and compressor control modules in remote environments.

-

Process Manufacturing: Ensures stable instrumentation control in chemical, paper, and steel plants.

Advantages

-

High Signal Integrity: Eight-layer design with optimized ground planes minimizes electromagnetic interference.

-

Robust Protection: Built-in transient suppression and ESD safeguards protect downstream equipment.

-

Diagnostic Transparency: LED indicators and self-test firmware simplify maintenance and fault isolation.

-

Wide Environmental Tolerance: Reliable operation under extreme temperature, vibration, and humidity conditions.

-

Seamless Integration: Native compatibility with GE Mark VIe and other GE automation ecosystems.

-

Long Service Life: High-grade FR4 substrate and conformal coating extend operational longevity.

Frequently Asked Questions (FAQ)

-

What type of bus communication is supported by the IS210BPPH2BLD?

It supports a high-speed internal backplane bus compatible with Mark VIe system architecture. -

How is signal integrity maintained across the multilayer board?

Ground and power planes are strategically placed to reduce crosstalk and maintain low impedance paths. -

Does the board provide galvanic isolation between I/O sections?

Yes, opto-isolators are used for critical I/O channels to prevent ground loops. -

What diagnostic protocols are available for remote monitoring?

It supports Mark VIe diagnostic communications and Modbus/TCP for supervisory systems. -

How does the board handle power surges or transient spikes?

Integrated TVS diodes and surge suppressors protect sensitive circuitry. -

Is there onboard firmware for self-testing?

Yes, embedded firmware runs power-on self-tests and reports status to the control processor. -

What is the maximum supported data throughput?

Up to 66 MHz logic bus frequency, supporting high-speed real-time control loops. -

Can the board be hot-swapped in a live system?

It can be hot-inserted if the backplane segment is properly de-energized and configured for redundancy. -

What grounding scheme is recommended for installation?

A single-point earth ground with low impedance is recommended to minimize noise. -

How is thermal management ensured without active cooling?

Large copper planes and strategic component placement enable efficient heat dissipation under natural convection.

Related Models – Same Series or Function

| Model | Description |

|---|---|

| IS210BPPH2BRD | Variant with redundant interface circuitry |

| IS210BPPG1A | General-purpose logic and signal conditioning board |

| IS210BPPH1B | Earlier version supporting legacy Mark VI systems |

| IS210BPPAH2C | Advanced processor interface PCB |

| IS210BPPCG1A | Compact board for space-constrained control cabinets |

| IS210BPPJH2D | High-density I/O interface board |

Popular GE Control System Models

| Model | Description |

|---|---|

| IS200DSPXH1D | Digital signal processor board for Mark VIe |

| IS200STCIH6A | Simplex contact input terminal board |

| IS200TRPGH2B | Primary trip terminal board with redundant trip channels |

| IS200VCRCH1B | VME communication controller for turbine control |

| IS210AEPSG2B | High-efficiency power board |

| IS210VSPAH1A | Monitoring assembly module for vibration analysis |

Excellent PLC

Excellent PLC