| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

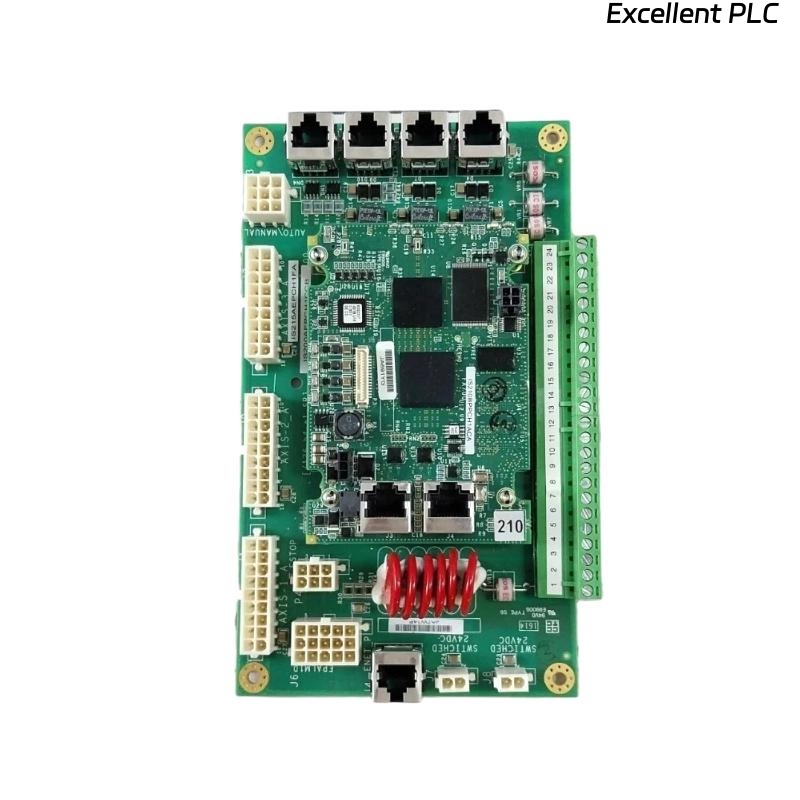

The GE IS215AEPCH1E Turbine Control Board is an advanced control module engineered for the GE Mark VIe and Mark VIeS turbine management systems. It serves as the primary interface for executing real-time turbine control, including fuel regulation, speed monitoring, and trip logic. Designed for harsh industrial environments, this board integrates high-speed processors, redundant communication paths, and advanced I/O capabilities to ensure stable and precise turbine operations. Its rugged construction and firmware architecture support mission-critical applications in power generation, oil & gas, and other heavy industries where continuous operation and high availability are essential.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS215AEPCH1E |

| Product Type | Turbine Control Board |

| Function | Executes turbine control algorithms and communicates with field devices |

| Processor | High-performance industrial CPU with real-time operating system |

| Memory | 512 MB DDR SDRAM, 128 MB non-volatile flash |

| Communication Interfaces | Dual redundant Ethernet (10/100 Mbps), RS-232/RS-485 serial ports |

| Power Supply Requirement | 28 V DC nominal (operating range 18–32 V DC) |

| Redundancy | Supports hot-standby and dual-channel redundancy |

| I/O Capability | Direct interface with Mark VIe I/O packs and Modbus-compatible devices |

| Environmental Rating | –40 °C to +70 °C, 5–95 % RH non-condensing |

| EMI/EMC Compliance | IEC 61000-6-2 and IEC 61000-6-4 industrial standards |

| Shock/Vibration Resistance | 30 g shock, 5 g vibration (10–2000 Hz) |

| Cooling Method | Passive convection |

| Dimensions (W×H×D) | 300 x 210 x 35 mm |

| Weight | 1.1 kg |

| Mounting | Standard Mark VIe rack slot |

| Certifications | CE, UL, RoHS compliant |

Applications

-

Gas and Steam Turbines – Manages start-up, shutdown, and load control sequences with deterministic precision.

-

Power Generation Plants – Integrates with plant DCS systems for real-time turbine and generator control.

-

Oil & Gas Facilities – Supervises compressor and pump operations in upstream and downstream applications.

-

Industrial Automation – Coordinates high-speed process control in steel, paper, and chemical manufacturing.

-

Combined-Cycle Plants – Optimizes interaction between gas and steam turbine operations.

-

Renewable Integration – Enables stable turbine operation in hybrid renewable power systems.

Advantages

-

High-Speed Processing – Ensures real-time response for complex turbine control algorithms.

-

Built-in Redundancy – Hot-standby operation provides continuous control during hardware faults.

-

Flexible Communication – Multiple Ethernet and serial ports simplify integration with legacy or modern networks.

-

Industrial-Grade Durability – Wide temperature range and strong vibration resistance allow use in extreme conditions.

-

Easy Maintenance – Online diagnostics, LED indicators, and firmware upgrades reduce downtime.

-

Scalable Architecture – Compatible with small to large Mark VIe installations and future expansions.

Frequently Asked Questions (FAQ)

-

How does the IS215AEPCH1E achieve deterministic turbine control?

The board runs a real-time operating system with prioritized scheduling, ensuring predictable execution of control loops. -

What redundancy methods are available for continuous operation?

It supports dual-channel and hot-standby configurations, automatically switching to a backup controller if a fault is detected. -

Which communication protocols can be used to interface with external systems?

Native protocols include Modbus TCP/RTU and Ethernet Global Data (EGD), along with standard serial communications. -

Can this board be integrated with non-GE Distributed Control Systems?

Yes, integration is supported via Modbus or through gateway devices that bridge to other industrial protocols. -

What diagnostic tools are available for field troubleshooting?

On-board LEDs, event logs, and self-test routines provide immediate status information and fault isolation data. -

How is firmware updated without interrupting turbine operation?

Firmware can be upgraded online using GE ControlST software, allowing seamless updates during normal operations. -

What measures protect against electromagnetic interference?

The board complies with IEC 61000-6-2 immunity and 61000-6-4 emissions standards, with extensive shielding and grounding. -

How does the board retain data during unexpected power loss?

Critical configuration and operational data are stored in non-volatile flash memory to maintain system integrity. -

Is there built-in support for high-speed data acquisition?

Yes, the CPU and high-bandwidth interfaces allow sub-millisecond data sampling for turbine performance monitoring. -

Can the module operate in high-vibration turbine enclosures?

Absolutely; it is tested for up to 30 g shock and 5 g vibration to maintain reliable operation in turbine environments.

Related Models – Same Series

| Model | Description |

|---|---|

| IS215AEPCH1D | Previous revision of the AEPCH1E with similar control capabilities |

| IS215ACLEH1A | Application control layer module for Mark VIe systems |

| IS215UCVEH2A | Universal controller with expanded communication options |

| IS215UPSCG1A | UPS interface control board for Mark VIe applications |

| IS215VPROH1B | Protection processor board for critical turbine control |

| IS215UCCAM03A | Communication adapter module for high-speed data transfer |

Popular GE Control System Models

| Model | Description |

|---|---|

| IS210AEPSG2B | Advanced power supply board for Mark VIe |

| IS210BPPH2BLD | High-density printed circuit control board |

| IS210JPDHG1A | DIN-rail power and communication distribution module |

| IS200TRPGH2B | Primary trip terminal board with redundant safety channels |

| IS210VSPAH1A | Vibration monitoring assembly module |

| IS215ACLAH1AD | Application control layer module for high-speed processing |

Excellent PLC

Excellent PLC