| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

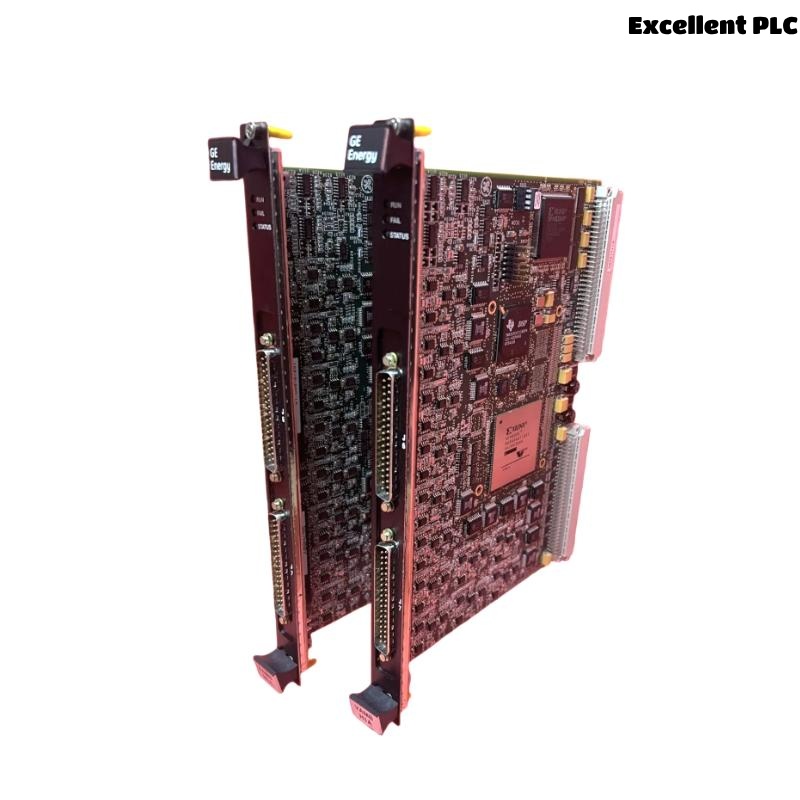

The GE IS215VAMBH1A Acoustic Monitoring Card Assembly Module is a high-performance acoustic vibration monitoring module designed to be used with GE Mark VIe and Mark VI turbine control and monitoring systems. It belongs to GE’s Speedtronic™ product family, which is trusted globally for gas and steam turbine protection, diagnostics, and control.

The IS215VAMBH1A is specifically engineered to detect and analyze high-frequency acoustic signals emitted by turbines and rotating equipment, allowing for the early detection of potential mechanical faults such as blade cracks, bearing defects, flow disturbances, or combustion instability.

By capturing and processing these acoustic emissions in real-time, the module provides plant operators with precise, actionable data on equipment health—enabling condition-based maintenance, minimizing unplanned outages, and extending equipment life.

With seamless VMEbus architecture, high-speed processing, and compatibility with a wide range of sensors, the IS215VAMBH1A is a vital component in modern predictive maintenance systems deployed across power generation, oil & gas, and heavy industry sectors.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | GE IS215VAMBH1A Acoustic Monitoring Card Assembly Module |

| Part Number | IS215VAMBH1A |

| System Compatibility | GE Mark VI, Mark VIe, Speedtronic™ |

| Module Type | Acoustic Vibration Monitoring Card |

| Signal Input | Acoustic signals from high-frequency sensors |

| Frequency Range | Typically 20 kHz – 100 kHz (depends on sensor) |

| Analog-to-Digital Converter | High-resolution ADC for acoustic signal sampling |

| Data Processing | Real-time FFT, RMS, peak detection |

| Sensor Compatibility | Wide range of acoustic emission sensors |

| CPU | Embedded industrial-grade DSP/CPU |

| Communication Interfaces | Ethernet 10/100 Mbps, VMEbus |

| Supported Protocols | Ethernet/IP, proprietary GE protocols |

| Diagnostics | Real-time self-tests and alarm reporting |

| Redundancy Support | Yes — supports redundant monitoring architectures |

| Firmware Upgrade | Field upgradeable via Ethernet |

| Power Supply | 5 VDC via VME backplane |

| Power Consumption | Approx. 15 W typical |

| Operating Temperature Range | -30°C to +65°C (-22°F to +149°F) |

| Storage Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Relative Humidity Range | 5% to 95% RH (non-condensing) |

| Vibration Compliance | IEC 60068-2-6 |

| Shock Compliance | IEC 60068-2-27 |

| PCB Protection | Conformal coating for industrial environments |

| Dimensions (H x W x D) | 233 x 20 x 160 mm |

| Weight | 0.45 kg |

| Mounting Method | Single-slot VME rack mount |

| Certifications | CE, UL, CSA, RoHS compliant |

Applications

-

Gas turbine acoustic condition monitoring

-

Steam turbine blade crack detection

-

Combustion chamber monitoring in turbines

-

Acoustic vibration monitoring in large rotating equipment

-

Predictive maintenance programs for critical machinery

-

Balance of Plant (BoP) auxiliary equipment monitoring

-

Monitoring of bearing and gearbox health

-

Acoustic analysis for pipeline compressor stations

-

Real-time detection of flow-induced noise anomalies

-

Early warning system in mission-critical rotating machinery in oil & gas and process industries

Product Advantages

-

High-frequency signal detection for early fault identification

-

Real-time FFT analysis and diagnostics

-

Seamless integration into GE Mark VI/VIe platforms

-

Supports a wide variety of industrial acoustic sensors

-

Redundant system support ensures continuous monitoring

-

Industrial-grade durability with conformal-coated PCB

-

Compact single-slot design — space-saving in VME racks

-

Helps prevent catastrophic failures with early detection

-

Supports condition-based maintenance and reduces O&M costs

-

Field-proven in critical applications in power, oil & gas, and heavy industries

Frequently Asked Questions (FAQ)

-

What does the IS215VAMBH1A module monitor?

It monitors high-frequency acoustic emissions from turbines and other rotating machinery. -

How does acoustic monitoring benefit my plant?

It allows early detection of faults such as cracks, flow disturbances, or combustion instability—enabling preventative maintenance and avoiding unexpected outages. -

What types of sensors are compatible with this module?

It is compatible with a wide range of industrial acoustic emission sensors. -

Can it integrate with GE Mark VIe systems?

Yes — the module is fully compatible with both Mark VI and Mark VIe platforms. -

What is the typical frequency range monitored?

Typically from 20 kHz to 100 kHz, depending on sensor configuration. -

Does the module support redundancy?

Yes — it supports redundant configurations for high-reliability monitoring systems. -

How is data processed?

The module performs real-time FFT, RMS, and peak detection to analyze acoustic signals. -

How is the module protected in harsh environments?

The PCB is conformal coated, and the unit meets industrial vibration and shock standards. -

Is the firmware field upgradeable?

Yes — firmware can be upgraded via Ethernet without system downtime. -

Can this module be used outside turbine applications?

Absolutely — it can monitor bearings, gearboxes, compressors, and other rotating equipment in various industries.

Related Models (Same Series or Product Line)

| Model Number | Description |

|---|---|

| IS215UCVEH2A | High-performance Universal Controller |

| IS215VCMIH2C | VME Communication Interface Module |

| IS215VPROH2B | Protection Interface Module |

| IS215ACLEH1A | Application Control Layer Module |

| IS200VCRCH1B | Rack Controller Processor |

| IS200STCIH6A | Simple Thermocouple Input Module |

Popular GE Models (Same Brand)

| Model Number | Description |

|---|---|

| Mark VIe Control System | Advanced Gas/Steam Turbine Control System |

| IS200VCMIH2C | VME Communication Interface Module |

| IS200TREGH1B | Trip Emergency Generator Interface |

| IS200DAMAG1B | Digital Input Module |

| IS200SPIDG1ABA | Simple PID Control Module |

| IS200SRTDH2A | RTD Input Module |

Excellent PLC

Excellent PLC