| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

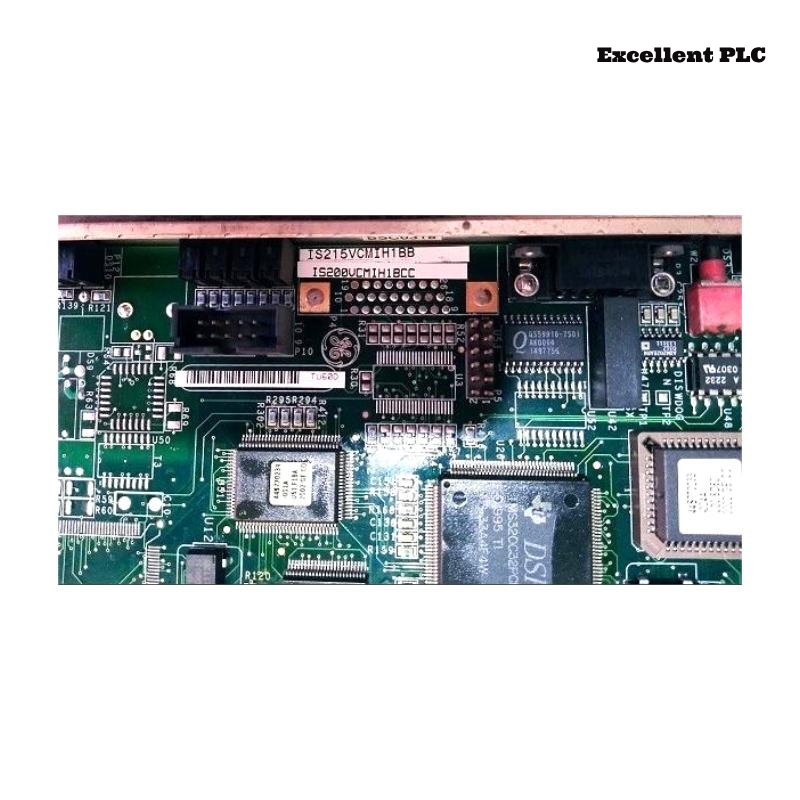

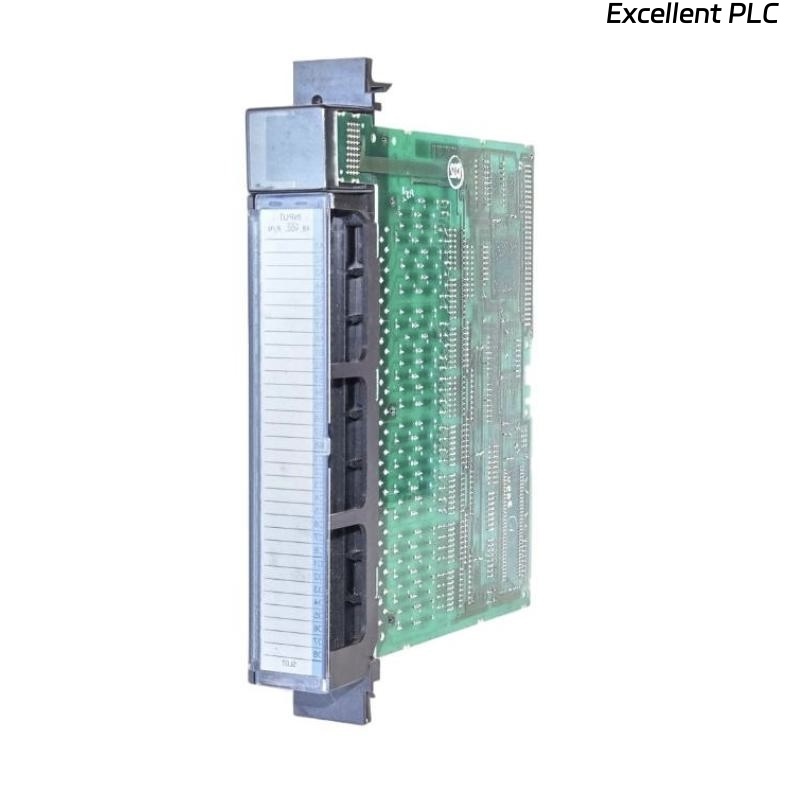

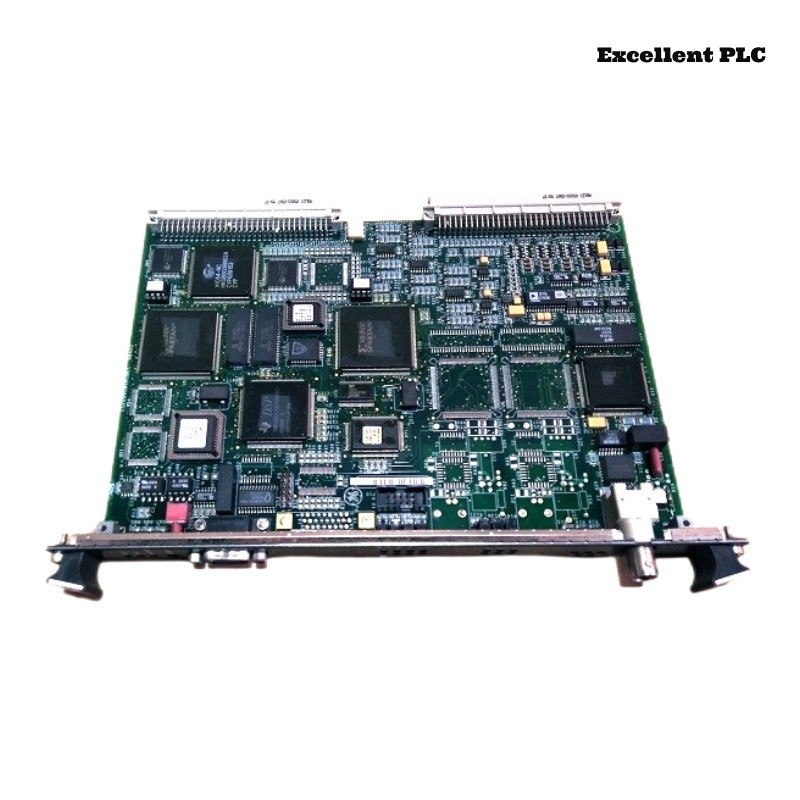

Product Overview:

The GE IS215VCMIH1B is a VCMI Bus Master Controller Board designed for integration within the Mark VI system, a part of GE’s Speedtronic series for gas and steam turbine control. This board serves as a critical communication interface, ensuring seamless data exchange between the controller and Input/Output (I/O) boards, as well as the system control network known as IONet.

Product Specifications

| Specification | Details |

|---|---|

| Part Number | IS215VCMIH1B |

| Manufacturer | General Electric (GE) |

| Series | Mark VI |

| Function | VCMI Bus Master Controller |

| Communication | VME Bus Interface, IONet (with options for one or three Ethernet ports depending on system configuration) |

| Power Supply | 5V DC |

| Dimensions | 200 x 120 x 60 mm |

| Weight | 1.2 kg |

| Connectors | – One serial port – Up to three IONet Ethernet ports (depending on system configuration) – LED indicators for “Run,” “Fail,” and “Status” |

| Compatibility | Designed for use within GE’s Mark VI control systems, compatible with both simplex and Triple Modular Redundancy (TMR) configurations. |

| Environmental | Designed for industrial environments; specific operating temperature and humidity ranges not provided in available sources. |

| Certifications | Complies with relevant industrial standards for turbine control systems (specific certifications not detailed in available sources). |

| Mounting | Single-slot VME rack mount |

| Redundancy | Supports TMR configurations with three separate IONet ports for communication with three I/O channels (Rx, Sx, and Tx) and with two other control modules. |

| ID Management | Manages IDs for all boards within its rack and their associated terminal boards. |

| Internal Communication | Communicates internally to the I/O boards in its rack and to other IS215VCMIH1B cards through the IONet. |

| System Integration | Enhances system integration by serving as a VME Bus Master Controller, enabling better coordination and synchronization of components within the GE Mark VI system. |

Product Applications

The IS215VCMIH1B is primarily utilized in industrial settings for the management and control of gas and steam turbines. Its applications include:

-

Turbine Control Systems: Serving as a communication hub within GE’s Mark VI system, it ensures efficient data exchange between controllers and I/O devices, facilitating precise turbine operation.

-

Industrial Process Automation: By managing communication interfaces, it plays a vital role in automating processes in power plants and other industrial environments where turbines are employed.

-

System Monitoring and Diagnostics: The board’s ability to manage IDs and facilitate communication allows for real-time monitoring and diagnostics of turbine systems, aiding in predictive maintenance and reducing downtime.

Product Advantages

The IS215VCMIH1B offers several key advantages:

-

Enhanced Communication: With its VME Bus Interface and IONet connectivity, the board ensures reliable and high-speed communication within the system, leading to improved performance.

-

System Integration: Acting as a VCMI Bus Master Controller, it enhances system integration, enabling better coordination and synchronization of components within the GE Mark VI system.

-

Flexibility: The availability of configurations with one or three Ethernet ports allows it to be tailored to different system requirements, supporting both simplex and TMR systems.

-

Reliability: Designed for industrial environments, the board is built to withstand the demanding conditions of turbine control systems, ensuring long-term reliability.

Frequently Asked Questions (FAQs)

-

What is the purpose of the GE IS215VCMIH1B VCMI Bus Master Controller Board?

The GE IS215VCMIH1B serves as a crucial part of the GE Mark VI control system, acting as a communication interface between the controller and various I/O devices in gas and steam turbine systems. It handles the data exchange between different system components and ensures proper operation and integration of the turbine control system. -

Is the GE IS215VCMIH1B compatible with other turbine control systems outside of the Mark VI?

No, the IS215VCMIH1B is specifically designed for use with the GE Mark VI turbine control system. It is not compatible with other turbine control systems as it is optimized for Mark VI configuration and communication protocols. -

How does the IS215VCMIH1B facilitate communication between system components?

The board communicates via the VME bus interface and IONet, a dedicated communication network within the GE Mark VI system. It supports both simplex and TMR (Triple Modular Redundancy) configurations, ensuring continuous and reliable communication in turbine control applications. -

What are the key features of the IS215VCMIH1B regarding redundancy?

The IS215VCMIH1B supports TMR configurations, providing enhanced system reliability. This means that the system can operate with three separate communication paths, ensuring that failure of one path does not lead to a loss of functionality, which is critical for safety in turbine control applications. -

How does the board contribute to system diagnostics?

The IS215VCMIH1B allows for real-time monitoring of the turbine system. It helps detect faults or performance issues by communicating diagnostic data and status reports across the IONet. This feature is vital for predictive maintenance, enabling operators to address potential issues before they lead to system downtime. -

What types of power supply does the GE IS215VCMIH1B require?

The IS215VCMIH1B operates with a 5V DC power supply, which is standard for most VME-based controller boards in turbine control systems. Proper voltage regulation is essential for maintaining stable operation of the board and the entire system. -

Can the IS215VCMIH1B handle large data transfer requirements?

Yes, the IS215VCMIH1B is designed to handle significant data traffic within the control system. Its integration into the IONet allows it to efficiently manage large amounts of data exchange between various components of the turbine system, ensuring timely and accurate control decisions. -

What role does the IS215VCMIH1B play in system synchronization?

The board plays a vital role in synchronizing multiple system components by managing the communication between the controller and I/O devices. This ensures that all components within the turbine system operate in harmony, which is essential for optimizing performance and efficiency. -

Is the GE IS215VCMIH1B easily upgradeable?

The IS215VCMIH1B is part of the GE Mark VI system, which is designed to be scalable and upgradable. While the board itself may not require frequent upgrades, the overall system can be enhanced with new software or hardware components to meet evolving operational needs. -

What environmental conditions is the IS215VCMIH1B designed to withstand?

The IS215VCMIH1B is built to perform reliably in industrial environments, including power plants and other industrial sites. It is designed to handle the vibrations, temperature variations, and electromagnetic interference commonly encountered in turbine control applications.

Recommended Related and Popular Models

| Related Model | Product Description | Key Features |

|---|---|---|

| GE IS215VCMIH1A | A previous version of the VCMI Bus Master Controller in the same series. | Similar functionality with slight differences in communication protocols and redundancy options. |

| GE IS215VCOMH1 | VCMI Communication Module for integration in the Mark VI system. | Provides additional communication options for expansion in larger systems. |

| GE IS215VAMIH1B | VCMI I/O Module for Mark VI system integration. | Connects I/O devices to the Mark VI system, ensuring reliable data transmission. |

| GE IS215ACMSH1 | Advanced controller board for turbine control. | Handles advanced control algorithms with increased performance capabilities. |

| GE IS215VPSMH1 | Power supply module for the Mark VI system. | Ensures stable power delivery to the system components, preventing interruptions. |

| GE IS215CMMIH1 | Control Module for Mark VI system. | Integrates control systems with turbine processes, facilitating automation and real-time adjustments. |

| GE IS215VCOMH1B | Enhanced communication board for the GE Mark VI system, designed for faster data handling. | Provides faster data transfer rates for more demanding control applications. |

| GE IS215CICS | Integrated Control System board for turbine management. | Optimized for centralized control of turbine operations, improving efficiency. |

| GE IS215ECOC | Enhanced communications controller for Mark VI. | Supports robust communication in high-demand industrial environments. |

| GE IS215MOTC | Motor control board for turbine systems. | Manages motor functions with precise control and synchronization. |

Popular GE Models

| Model | Product Description | Key Features |

|---|---|---|

| GE 07KT98C | High-performance turbine controller in GE’s Speedtronic series. | Advanced fault tolerance, high-speed data exchange, and integration with other GE systems. |

| GE IS200EISBH1A | A critical component in GE’s turbine control system, part of the IS200 series. | Provides extensive diagnostics and fault tolerance features. |

| GE IS200TRLYH1 | Relay interface board for turbine control. | Handles relay switching for turbine safety and operational control. |

| GE IS200DSPXH1 | Digital signal processor module used in turbine control. | Improves signal processing accuracy for real-time turbine monitoring. |

| GE 07EA61 GJR5250300R0101 | Controller module used for power plant automation systems. | Reliable communication and data exchange within industrial power systems. |

| GE IS200CTURH1 | Turbine control and protection relay board. | Features advanced protection algorithms for turbine safety and operational continuity. |

| GE 07AC91 | Integrated control system for turbine management. | Integrates advanced control algorithms with remote access features. |

| GE 07AK92 | Auxiliary control module for GE turbine control systems. | Supports auxiliary systems and provides remote diagnostics for better system management. |

| GE IS200EPBAG1A | A flexible I/O module for industrial applications. | Offers high flexibility for integrating various industrial sensors and actuators. |

| GE IS200RAMP | Ramp module for industrial automation in turbine control. | Provides controlled ramp-up and ramp-down capabilities to avoid system overloading and damage. |

Excellent PLC

Excellent PLC