| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

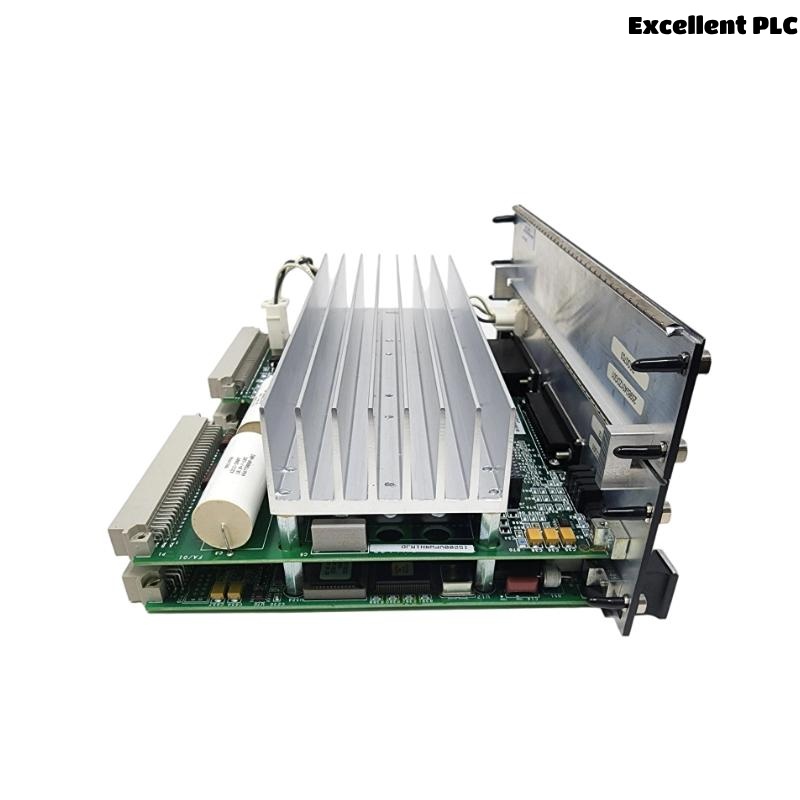

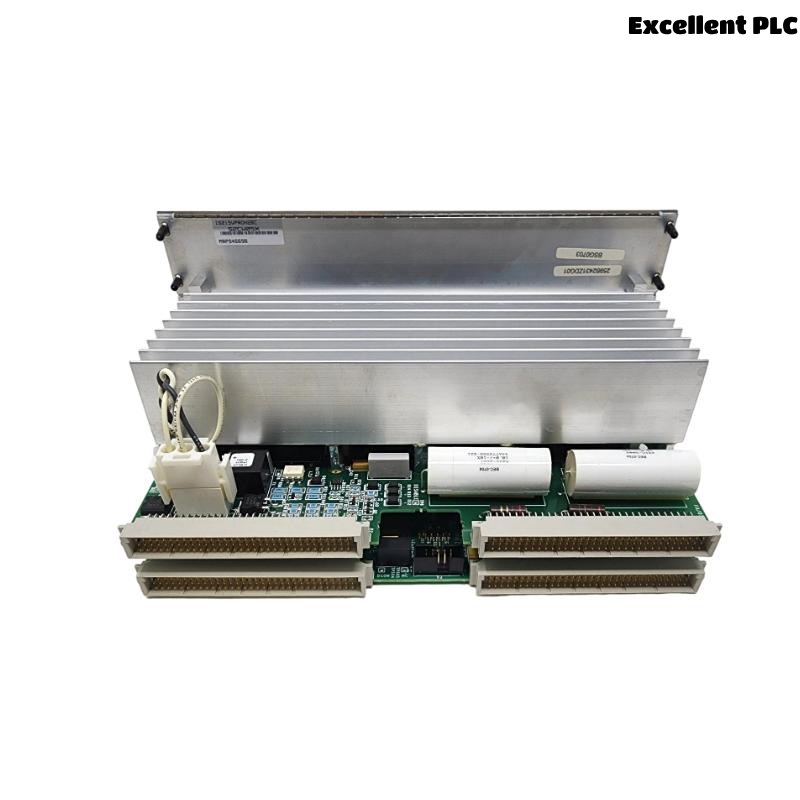

Product Introduction

The GE IS215VPROH2B Turbine Protection Board is an advanced, high-performance protection and monitoring module designed for use in GE Mark VI and Mark VIe turbine control systems. It belongs to the globally trusted GE Speedtronic™ family, which is the industry standard for the protection, monitoring, and control of gas turbines, steam turbines, and critical rotating equipment.

As an integral part of turbine protection architecture, the IS215VPROH2B is responsible for acquiring, processing, and analyzing critical protection signals — including overspeed, vibration, temperature, shaft position, and other key parameters — to ensure the safe operation of turbines.

The board continuously monitors these vital measurements and initiates protective actions (such as emergency trip commands) when preset thresholds are exceeded. It provides fast, deterministic protection logic to minimize risk and prevent catastrophic equipment failure in demanding environments like power plants, oil & gas facilities, and chemical plants.

The IS215VPROH2B seamlessly integrates with the VMEbus rack architecture of Mark VI/VIe systems and supports redundant configurations for maximum reliability. It also features advanced self-diagnostics, allowing operators to verify system health and improve maintenance scheduling.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | GE IS215VPROH2B Turbine Protection Board |

| Part Number | IS215VPROH2B |

| System Compatibility | GE Mark VI, Mark VIe, Speedtronic™ |

| Module Type | Turbine Protection and Monitoring Module |

| Protection Functions | Overspeed, vibration, shaft position, flame detection, emergency trip logic |

| Signal Input | Analog and digital protection signals |

| CPU | Industrial-grade embedded processor |

| Processing Capabilities | Real-time protection algorithms and logic execution |

| Trip Outputs | Relay-based trip outputs (hardwired to mechanical trip systems) |

| Redundancy Support | Yes — supports redundant configurations |

| Communication Interfaces | Ethernet 10/100 Mbps, VMEbus |

| Data Logging | Yes — onboard event and alarm logging |

| Diagnostics | Advanced self-tests, system health monitoring |

| Firmware Upgrade | Field upgradeable via Ethernet |

| Power Supply | 5 VDC via VME backplane |

| Power Consumption | Approx. 18 W typical |

| Operating Temperature Range | -30°C to +65°C (-22°F to +149°F) |

| Storage Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Relative Humidity Range | 5% to 95% RH (non-condensing) |

| Vibration Compliance | IEC 60068-2-6 |

| Shock Compliance | IEC 60068-2-27 |

| PCB Protection | Conformal coating for industrial environments |

| Dimensions (H x W x D) | 330 x 178 mm |

| Weight | 0.45 kg |

| Mounting Method | Single-slot VME rack mount |

| Certifications | CE, UL, CSA, RoHS compliant |

Applications

-

Gas turbine protection systems

-

Steam turbine trip and protection logic

-

Overspeed protection for rotating equipment

-

Vibration-based trip and shutdown systems

-

Flame detection and combustion instability protection

-

Turbine shaft monitoring and protection

-

Emergency trip interface for plant-wide shutdown systems

-

Auxiliary equipment protection (compressors, pumps, gearboxes)

-

Critical protection for rotating machines in oil & gas facilities

-

Condition monitoring in power generation plants and refineries

Product Advantages

-

Real-time protection processing: Ultra-fast execution of trip logic and fault detection

-

Wide range of protection functions — overspeed, vibration, temperature, flame, shaft position

-

Redundant architecture support ensures uninterrupted protection

-

Seamless integration with Mark VI/VIe control systems

-

Designed for industrial harsh environments (shock, vibration, humidity)

-

Self-diagnostic capabilities enhance system reliability and maintenance planning

-

Compact, single-slot VME rack module saves cabinet space

-

Field upgradeable firmware — future-proofed and easy to maintain

-

Global certifications for safe operation in all major markets

-

Proven track record in power plants and critical process industries

Frequently Asked Questions (FAQ)

-

What is the primary function of the IS215VPROH2B?

It provides real-time turbine protection, monitoring key safety parameters and initiating emergency shutdowns when needed. -

Which systems is this module compatible with?

It works seamlessly with GE Mark VI and Mark VIe platforms. -

What protection functions are supported?

Overspeed, vibration, shaft position, flame detection, and other turbine trip logic. -

Does this board support redundancy?

Yes — it can be configured in redundant architectures for critical applications. -

What are the trip outputs?

The board supports relay-based hardwired trip outputs that interface directly with turbine mechanical trip systems. -

How is system health monitored?

Built-in self-tests and diagnostics continuously monitor board health and system readiness. -

Is the board suitable for gas and steam turbines?

Yes — it is used in both gas turbine and steam turbine protection applications. -

How is the firmware maintained?

Firmware is field upgradeable via Ethernet, allowing maintenance without downtime. -

What communication protocols are supported?

The board communicates via Ethernet/IP and VMEbus, supporting integration into DCS and turbine systems. -

Where is the IS215VPROH2B used?

Widely used in power generation, oil & gas, chemical processing, and other industries requiring turbine protection.

Related Models (Same Series or Product Line)

| Model Number | Description |

|---|---|

| IS215UCVEH2A | High-performance Universal Controller |

| IS215VCMIH2C | VME Communication Interface Module |

| IS215ACLEH1A | Application Control Layer Module |

| IS215VAMBH1A | Acoustic Monitoring Card |

| IS200VCRCH1B | Rack Controller Processor |

| IS200STCIH6A | Simple Thermocouple Input Module |

Popular GE Models (Same Brand)

| Model Number | Description |

|---|---|

| Mark VIe Control System | Advanced Gas/Steam Turbine Control System |

| IS200VCMIH2C | VME Communication Interface Module |

| IS200TREGH1B | Trip Emergency Generator Interface |

| IS200DAMAG1B | Digital Input Module |

| IS200SPIDG1ABA | Simple PID Control Module |

| IS200SRTDH2A | RTD Input Module |

Excellent PLC

Excellent PLC