| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

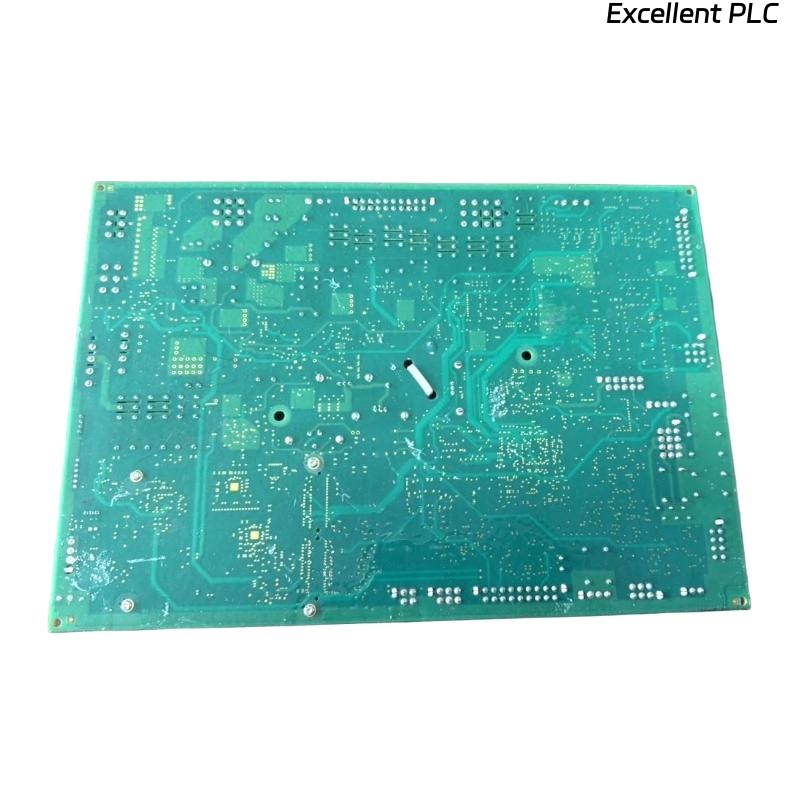

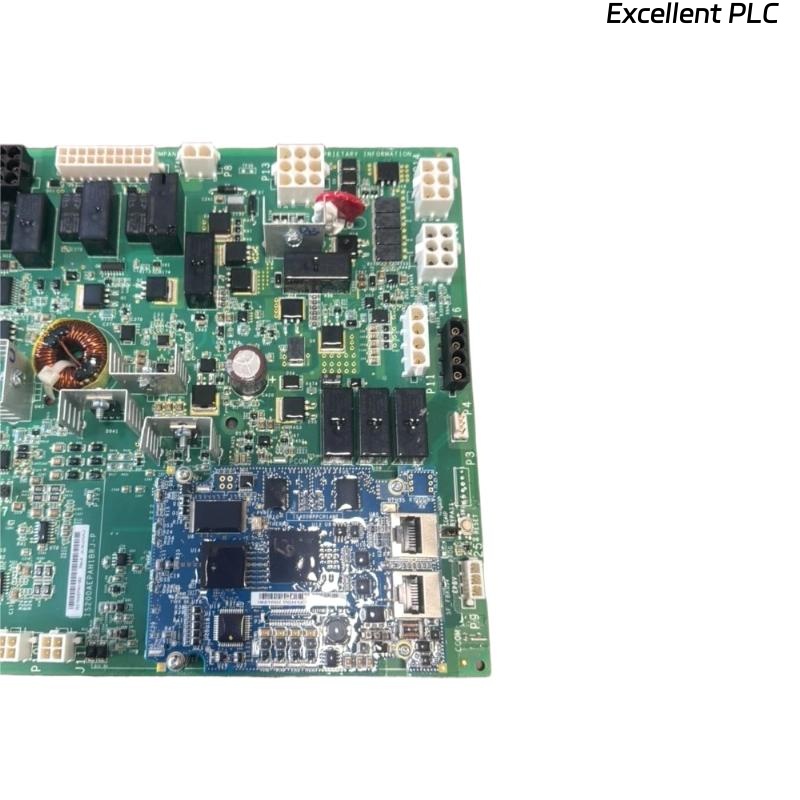

The GE IS215WEPAH1BD Wind Energy Pitch Axis Module is a specialized control module designed for advanced wind turbine pitch systems. It manages the precise control of blade pitch angles to optimize aerodynamic performance, maximize energy capture, and ensure safe operation during varying wind conditions.

Engineered for high reliability and precision, the IS215WEPAH1BD integrates advanced electronics for real-time monitoring and actuation of pitch motors. It communicates directly with the turbine’s main controller, providing feedback and executing commands to adjust blade angles accurately. This module is critical for performance optimization, load reduction, and protecting turbine components from mechanical stress.

The module is widely applied in onshore and offshore wind turbines, supporting turbine control, predictive maintenance, and system diagnostics.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS215WEPAH1BD |

| Product Type | Wind Energy Pitch Axis Module |

| Functionality | Blade pitch control, feedback monitoring, actuation management |

| Input Voltage | 24 VDC nominal (system-dependent) |

| Communication Interface | Fieldbus, proprietary GE wind turbine communication protocol |

| Feedback Input | Resolver, encoder, or sensor feedback |

| Control Output | Command signals to pitch motors |

| Operating Temperature Range | -20°C to +60°C |

| Storage Temperature Range | -40°C to +85°C |

| Protection Features | Overvoltage, short-circuit, and thermal protection |

| Mounting Type | Rack-mounted or slot-mounted in turbine control cabinet |

| Dimensions | 220 × 120 × 50 mm |

| Weight | 1.1 kg |

Applications

The IS215WEPAH1BD Pitch Axis Module is used in wind turbine control systems to ensure optimal performance and safety:

-

Blade Pitch Control: Provides precise angular control of turbine blades to adjust power output.

-

Load Reduction: Reduces mechanical stress on the turbine during high winds or emergency stops.

-

Turbine Protection: Executes safety commands during extreme weather or abnormal operating conditions.

-

Energy Optimization: Adjusts blade angles to maximize aerodynamic efficiency across varying wind speeds.

-

Monitoring and Diagnostics: Collects real-time feedback from pitch sensors for predictive maintenance.

-

Offshore and Onshore Turbines: Ensures reliable operation in challenging environmental conditions.

Advantages

-

High Precision Control: Ensures accurate blade positioning for optimal energy capture.

-

Robust Protection: Integrated overvoltage, short-circuit, and thermal safeguards protect both module and turbine components.

-

Real-Time Feedback Integration: Interfaces with sensors and encoders for continuous monitoring.

-

Reliability: Designed for continuous operation in demanding industrial and offshore environments.

-

Flexible Integration: Compatible with multiple turbine control systems and communication protocols.

-

Load Mitigation: Reduces mechanical stress on blades and drivetrain components.

-

Ease of Maintenance: Modular design allows quick replacement without shutting down the turbine.

-

System Compatibility: Seamless integration with GE wind turbine control architecture.

FAQ

-

What is the primary function of the IS215WEPAH1BD module?

It provides precise control of wind turbine blade pitch angles. -

Which feedback devices are supported by this module?

It supports resolvers, encoders, and other pitch sensor feedback systems. -

What type of output does the module generate for pitch motors?

It generates command signals for direct motor actuation. -

Can the module operate in offshore environmental conditions?

Yes, it is engineered for harsh environments, including offshore installations. -

How does the module protect against electrical faults?

It includes overvoltage, short-circuit, and thermal protection circuits. -

Is the module compatible with GE’s wind turbine controllers?

Yes, it is fully compatible with GE wind turbine control systems. -

Does it support real-time monitoring and diagnostics?

Yes, it continuously provides feedback to the main controller for predictive maintenance. -

What is the operating temperature range for reliable operation?

The module operates effectively between -20°C and +60°C. -

Can it reduce mechanical stress on the turbine during high wind conditions?

Yes, it actively adjusts blade angles to mitigate loads on blades and drivetrain. -

Is the module modular and replaceable without full turbine shutdown?

Yes, its design allows for hot-swapping in most rack configurations.

Related Models (Same Series or Similar)

| Model Number | Description |

|---|---|

| IS215WEPAH1BA | Pitch axis module for smaller turbine configurations |

| IS215WEPAH1BC | Enhanced precision module for offshore turbines |

| IS215WEPAH2BD | High-speed actuation module for rapid pitch adjustments |

| IS215WEPAH3BD | Extended feedback integration module with multiple sensors |

| IS215WEPAH4BD | Redundant pitch control module for high-reliability systems |

| IS215WEPAH5BD | Industrial-grade module with enhanced EMI protection |

Popular GE Models

| Model Number | Description |

|---|---|

| IS215WEPAH1AA | Standard wind energy pitch axis module |

| IS215WEPAH1AB | Medium-speed blade pitch control module |

| IS210AEAAH3B | Signal processing and control circuit board |

| IS215WEPAH1AC | Basic pitch control module for onshore turbines |

| IS215WEPAH1AD | Safety-rated pitch control module |

| IS215WEPAH1AE | High-precision module with integrated diagnostics |

Excellent PLC

Excellent PLC