| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

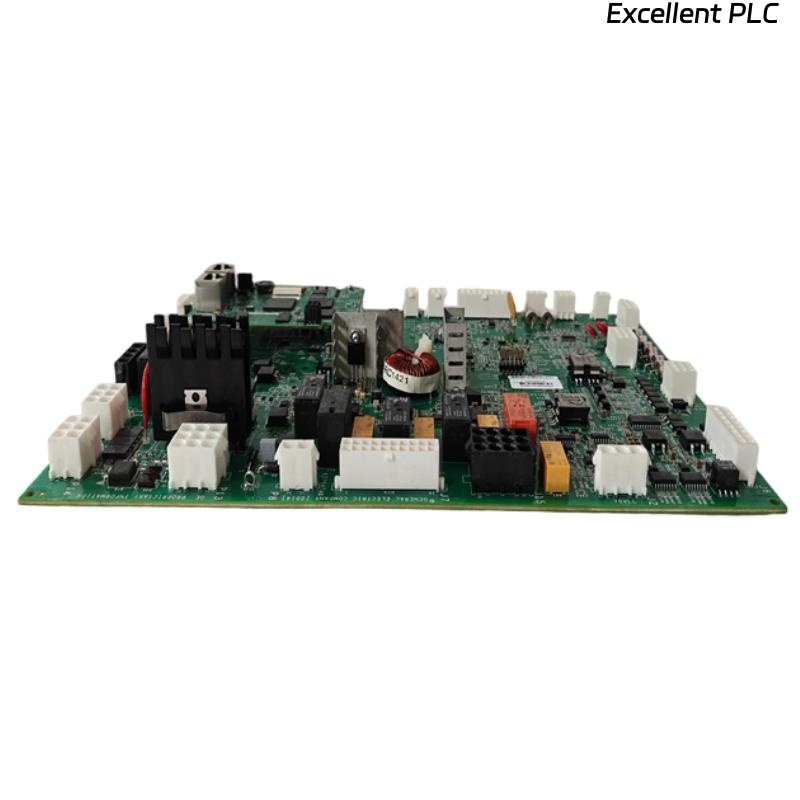

The GE IS215WEPAH2B Printed Circuit Board (PCB) is a high-performance electronic control module specifically designed for wind turbine pitch and control systems. It provides advanced processing, signal conditioning, and communication functions necessary for precise control of turbine components.

This PCB integrates microprocessors, memory circuits, and interface electronics to manage real-time data acquisition, actuation commands, and feedback signals from sensors. It is engineered to operate in harsh industrial environments, providing reliable performance in temperature fluctuations, electrical noise, and vibration conditions.

The IS215WEPAH2B is widely used in onshore and offshore wind turbine control systems, particularly in pitch axis control, ensuring optimal turbine efficiency, load management, and operational safety.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS215WEPAH2B |

| Product Type | Printed Circuit Board (Control Module) |

| Functionality | Signal processing, control logic, and communication interface |

| Input Voltage | 24 VDC nominal (system-dependent) |

| Supported Signals | Digital, analog, and sensor feedback |

| Microprocessor | Integrated high-speed microprocessor |

| Memory | RAM and non-volatile memory for configuration and data storage |

| Communication Interface | Proprietary GE wind turbine protocol, fieldbus compatible |

| Operating Temperature Range | -20°C to +70°C |

| Storage Temperature Range | -40°C to +85°C |

| Protection Features | Overvoltage, short-circuit, and thermal protection |

| Mounting Type | Rack-mounted or slot-mounted PCB |

| Dimensions | 210 × 110 × 35 mm |

| Weight | 1 kg |

Applications

The IS215WEPAH2B PCB is used extensively in wind turbine systems for:

-

Pitch Axis Control: Provides precise control of turbine blade angles for optimal aerodynamic performance.

-

Turbine Load Management: Reduces mechanical stress on blades and drivetrain during varying wind conditions.

-

Actuator Command Execution: Controls pitch motors based on feedback and system commands.

-

Monitoring and Diagnostics: Collects data from sensors for predictive maintenance and real-time monitoring.

-

Energy Optimization: Ensures blades are positioned to maximize energy capture from wind.

-

Safety Operations: Interfaces with the turbine control system for emergency shutdown and safe operation.

Advantages

-

High Precision Control: Delivers accurate blade positioning for improved turbine efficiency.

-

Robust Industrial Design: Resistant to electrical noise, thermal variations, and vibration.

-

Integrated Protection: Includes safeguards against overvoltage, short-circuit, and thermal overload.

-

Real-Time Feedback Integration: Works with sensors to provide accurate system status to the controller.

-

Reliability: Engineered for continuous operation in challenging offshore and onshore environments.

-

Flexible Connectivity: Compatible with multiple turbine communication protocols.

-

Modular Design: Enables easy replacement without requiring complete turbine shutdown.

-

System Optimization: Helps reduce mechanical stress and increase turbine lifespan.

FAQ

-

What is the primary function of the IS215WEPAH2B PCB?

It processes signals and controls pitch axis actuators in wind turbines. -

Which types of feedback does the board support?

The PCB supports resolver, encoder, and analog sensor feedback signals. -

What type of control outputs does it provide?

It provides command signals for pitch motor actuation. -

Can it operate in offshore wind turbine environments?

Yes, it is designed to operate in harsh environmental conditions. -

Does the module include protection against electrical faults?

Yes, it has overvoltage, short-circuit, and thermal protection. -

Is the IS215WEPAH2B compatible with GE turbine controllers?

Yes, it integrates seamlessly with GE wind turbine control systems. -

Can the board provide real-time monitoring data?

Yes, it continuously reports pitch position and actuator status to the main controller. -

What is the operating temperature range?

The board operates reliably between -20°C and +70°C. -

Can it reduce mechanical load on the turbine?

Yes, by accurately adjusting blade pitch according to wind conditions. -

Is it replaceable without shutting down the entire turbine?

Yes, its modular design allows for hot-swapping in most rack systems.

Related Models (Same Series or Similar)

| Model Number | Description |

|---|---|

| IS215WEPAH1BD | Pitch axis module for standard turbine control |

| IS215WEPAH2BD | High-speed PCB for pitch actuator control |

| IS215WEPAH3BD | PCB with multi-sensor integration for enhanced diagnostics |

| IS215WEPAH4BD | Redundant PCB for critical turbine control applications |

| IS215WEPAH5BD | Industrial-grade module with enhanced EMI protection |

| IS215WEPAH6BD | Advanced pitch control PCB with expanded I/O capabilities |

Popular GE Models

| Model Number | Description |

|---|---|

| IS215WEPAH1AA | Basic pitch axis module |

| IS215WEPAH1AB | Medium-speed blade control module |

| IS210AEAAH3B | Signal processing and control PCB |

| IS215WEPAH1AC | Onshore turbine pitch control module |

| IS215WEPAH1AD | Safety-rated pitch control PCB |

| IS215WEPAH1AE | High-precision module with integrated diagnostics |

Excellent PLC

Excellent PLC