| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

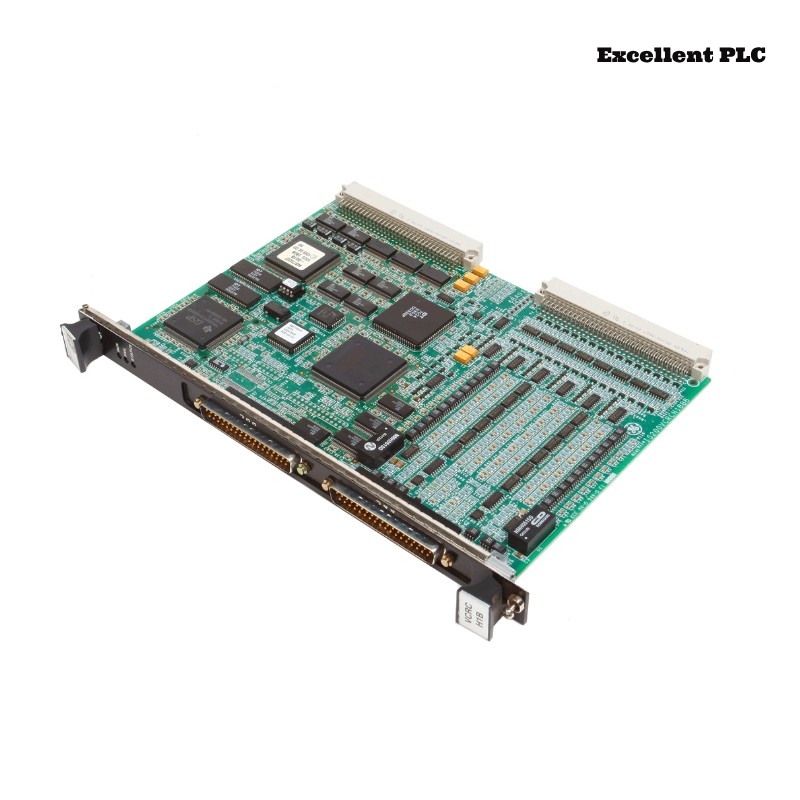

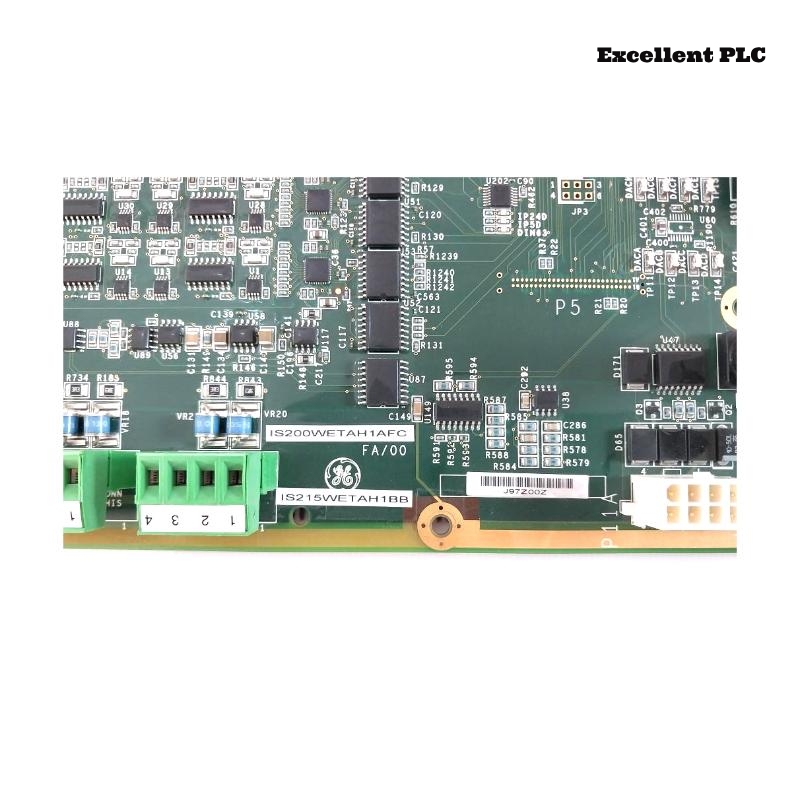

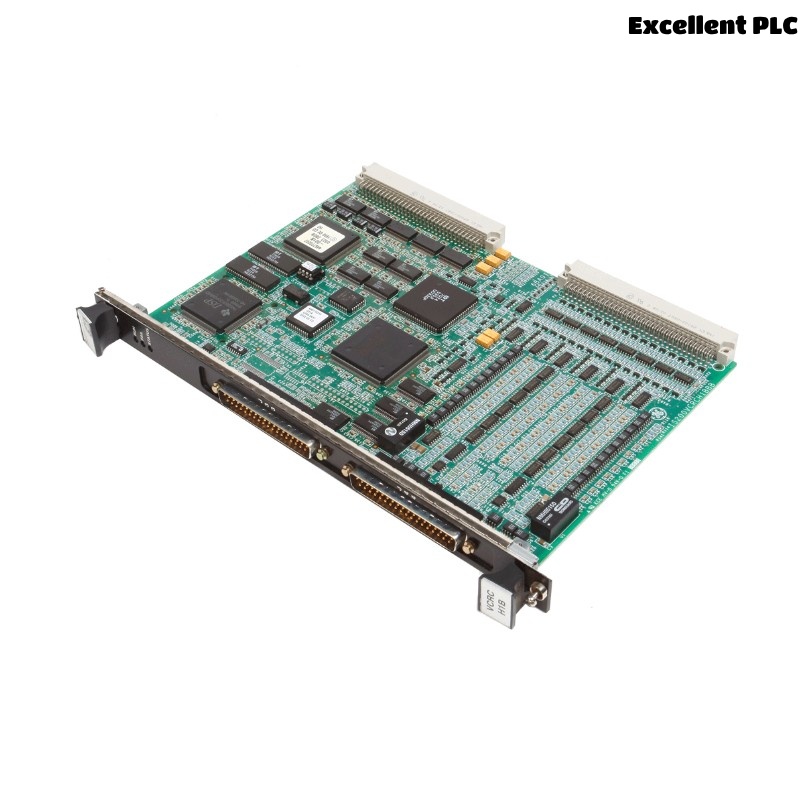

The GE IS215WETAH1BB WETA Top Box A Board is an integral component of the GE Mark VIe control system. This board plays a critical role in managing communication and control within industrial systems, particularly in power generation plants. It features advanced processing capabilities and provides multiple interfaces for seamless integration with other systems, sensors, and actuators in the network.

It is used in conjunction with other GE control system components to enhance the performance and reliability of turbines, generators, and other complex industrial machines.

Product Specifications

| Parameter | Description |

|---|---|

| Model | IS215WETAH1BB |

| Type | Top Box A Board |

| Power Consumption | 12W (typical) |

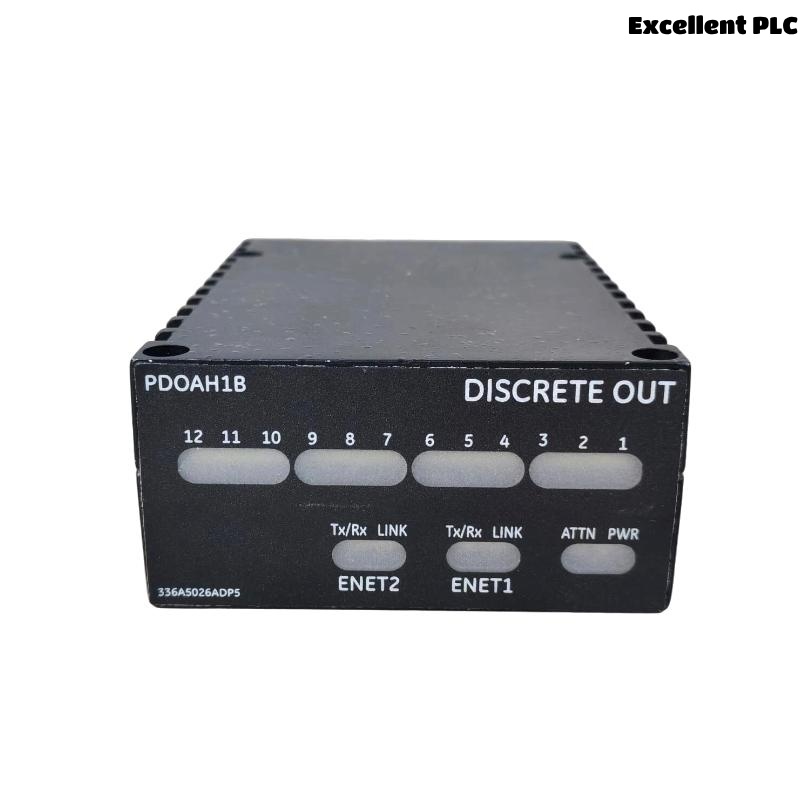

| Input/Output | 8 Digital Inputs / 8 Digital Outputs |

| Communication Ports | Ethernet, Serial, and Fieldbus ports |

| Dimensions (L x W x H) | 150 x 120 x 45 mm |

| Weight | 1.18 kg |

| Operating Temperature | -40°C to +85°C |

| Mounting Type | Double Slot, Chassis Mount |

| Redundancy Support | Yes (supports redundant configurations for mission-critical systems) |

| Compatibility | Compatible with GE Mark VIe control systems and other related devices |

Product Applications

The GE IS215WETAH1BB WETA Top Box A Board is used in a variety of industrial control systems, particularly within the following sectors:

- Power Generation: For controlling turbines, generators, and auxiliary equipment in power plants.

- Oil & Gas: Integrated in process control systems for gas and oil plants to manage critical operations.

- Chemical Processing: Controls automated systems, valves, and pumps in chemical production facilities.

- Manufacturing: Used in advanced manufacturing processes requiring high-precision control.

- Water Treatment: Monitors and manages operations in water and wastewater treatment facilities.

Product Advantages

- High Reliability: Ensures continuous operation in critical environments, with built-in redundancy options for added reliability.

- Seamless Integration: Easily integrates with other GE Mark VIe components, making it ideal for existing systems.

- Durability: Withstands harsh operating conditions such as extreme temperatures and environmental factors.

- Versatile Communication: Supports multiple communication protocols like Ethernet and Fieldbus, ensuring compatibility with a wide range of field devices and control networks.

- Compact Design: Designed with a compact and efficient layout, allowing for easier installation and space-saving in industrial control systems.

Latest Product News

- GE Unveils New Advanced Controller Boards for Industrial Automation – GE releases its latest IS215WETAH1BB WETA Top Box A Board, designed to support next-generation industrial control systems with enhanced reliability and performance in demanding environments.

- GE Enhances Power Plant Automation with Mark VIe Integrations – The IS215WETAH1BB is part of GE’s expanded Mark VIe offering, optimizing power plant control with more robust communication capabilities.

- GE’s Advanced Controller Boards for Oil & Gas Sector – GE’s IS215WETAH1BB WETA Top Box A Board is gaining popularity in the oil and gas sector for its efficient performance in offshore and onshore operations.

FAQ

-

What is the primary function of the IS215WETAH1BB WETA Top Box A Board?

- The IS215WETAH1BB serves as a crucial component in the GE Mark VIe control system, facilitating control and communication for industrial machinery like turbines and generators.

-

Which industrial sectors benefit the most from this board?

- Primarily used in power generation, oil and gas, chemical processing, and manufacturing sectors, the board optimizes control for critical infrastructure.

-

How does the IS215WETAH1BB integrate with existing systems?

- It integrates seamlessly with the GE Mark VIe control system and other compatible components, ensuring smooth system integration with existing hardware.

-

What communication protocols are supported by the IS215WETAH1BB?

- The board supports Ethernet, Fieldbus, and Serial communication protocols, allowing flexible and scalable system integration.

-

What is the board’s power consumption?

- The IS215WETAH1BB typically consumes 12W of power, making it energy-efficient for continuous industrial operation.

-

Can the board be used in harsh environmental conditions?

- Yes, it is designed to operate in temperatures ranging from -40°C to +85°C, making it suitable for a wide range of industrial environments.

-

What is the power requirement for the GE IS215WETAH1BB?

- The power requirements depend on the configuration and the devices connected to the board, but it typically operates at standard industrial voltages ranging from 24V to 48V DC

-

Does the board support redundancy?

- Yes, it supports redundant configurations, enhancing system reliability and ensuring continuous operation in case of failure.

-

What are the key advantages of the IS215WETAH1BB WETA Top Box A Board?

- Advantages include reliability, compact design, advanced communication capabilities, and seamless integration with GE Mark VIe systems.

-

How is the IS215WETAH1BB mounted in the system?

- he board is mounted using a double-slot configuration within a 6U chassis, ensuring secure and stable integration into the system.

Related Models (Same Series or Similar Models)

| Model | Type | I/O | Description |

|---|---|---|---|

| GE IS215UCDRH1BB | Universal Digital I/O Board | 16 In / 16 Out | General-purpose I/O board used in various industrial automation systems. |

| GE IS215UCVDH1BB | Universal Controller Board | 8 In / 8 Out | Provides communication and control functions for GE control systems. |

| GE IS215UCVDH5A | Universal Controller Board | 8 In / 8 Out | A universal I/O controller designed to provide modular control in industrial settings. |

| GE IS215UCBGH1A | Universal Control Board | 8 In / 8 Out | Used for process control, it ensures reliability in operations. |

| GE IS215UCDH1BB | Universal Controller Digital I/O | 8 In / 8 Out | Digital I/O controller for enhanced communication in automation applications. |

| GE IS215UCVDH6A | Controller Board | 8 In / 8 Out | Supports advanced control functions in complex industrial environments. |

| GE IS200VSNH1AAA | Vibration Monitoring Board | 8 In / 8 Out | Designed for vibration monitoring and predictive maintenance in turbines and generators. |

| GE IS200TRENH1A | Turbine Control Board | 8 In / 8 Out | Provides turbine control and monitoring capabilities for the power generation industry. |

| GE IS215TURB1A | Turbine Controller Board | 8 In / 8 Out | Control and monitor turbines for efficiency and reliability. |

| GE DS200TCPAG1A | Control Power Supply Board | N/A | Ensures stable power distribution to GE control systems in various industries. |

Popular GE Models

| Model | Type | I/O | Description |

|---|---|---|---|

| GE IS200VSDH1ABB | Vibration Monitoring Controller | 8 In / 8 Out | Provides vibration analysis for predictive maintenance. |

| GE DS200PCCAG1A | Power Control Board | 16 In / 16 Out | Optimizes power control and distribution in power plants. |

| GE IS200SNBCH1AAA | Servo Controller Board | 8 In / 8 Out | Used for motor control in industrial applications requiring high precision. |

| GE IS215VCMIH1AAA | Control Interface Board | 8 In / 8 Out | Interface for communication between various GE controllers and field devices. |

| GE DS200SBCAG1A | Safety and Control Board | 8 In / 8 Out | Provides safety monitoring and control capabilities for critical systems. |

| GE IS200TSAIH1A | Temperature Sensor Interface Board | 8 In / 8 Out | Monitors and controls temperature sensors in industrial automation. |

| GE IS215TURB1B | Turbine Control Board | 8 In / 8 Out | Facilitates control and monitoring for gas and steam turbines. |

| GE DS200SCCAG1A | System Control Board | 8 In / 8 Out | Used for system control and diagnostics in complex industrial processes. |

| GE IS215ULGHA1A | Universal Logic Board | 8 In / 8 Out | Provides enhanced logic processing for control systems. |

| GE DS200SDBAG1A | System Diagnostics Board | 8 In / 8 Out | Enables system diagnostics and fault detection for enhanced reliability in automation systems. |

Excellent PLC

Excellent PLC