| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

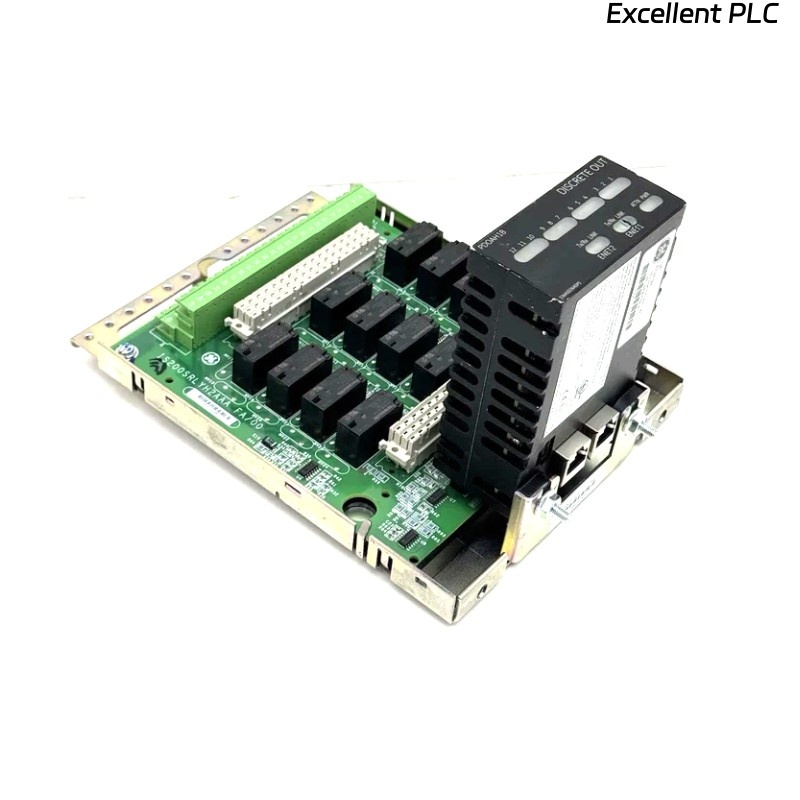

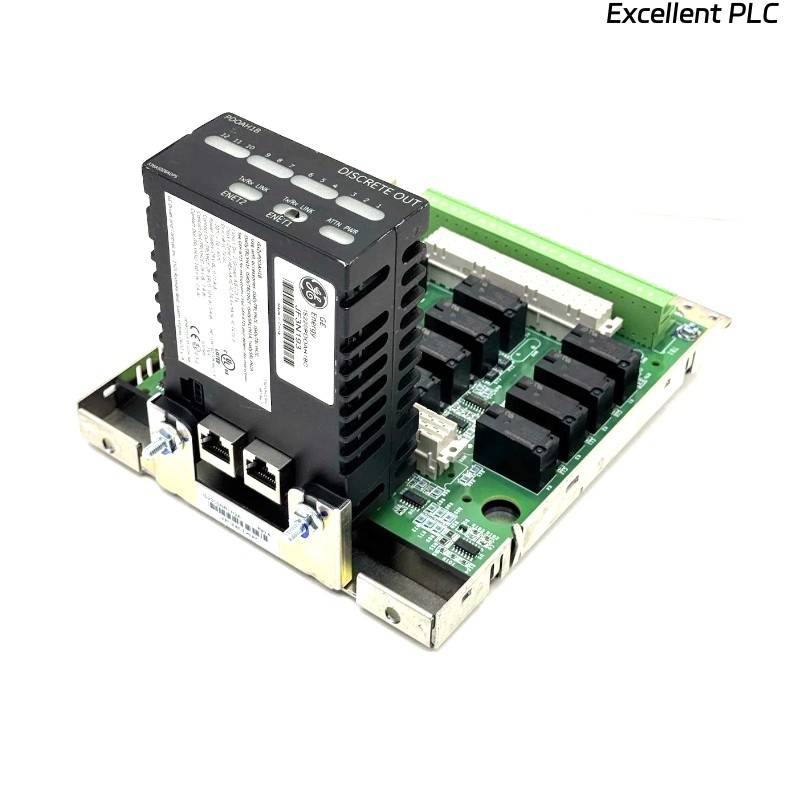

The GE IS230TNTRH1C Turbine Protection DIN Rail Module is part of GE’s ProSafe™ family of products, specifically designed to protect turbine control systems. This module provides critical monitoring and protection for turbine systems, helping prevent damage from various operational issues. The IS230TNTRH1C features a DIN rail mounting design, allowing for easy installation and integration into existing turbine protection systems. It supports a wide range of turbine configurations, making it suitable for diverse industrial applications.

Technical Specifications

| Parameter | Specification |

|---|---|

| Dimensions | 162 x 115 x 72 mm |

| Weight | 1 kg |

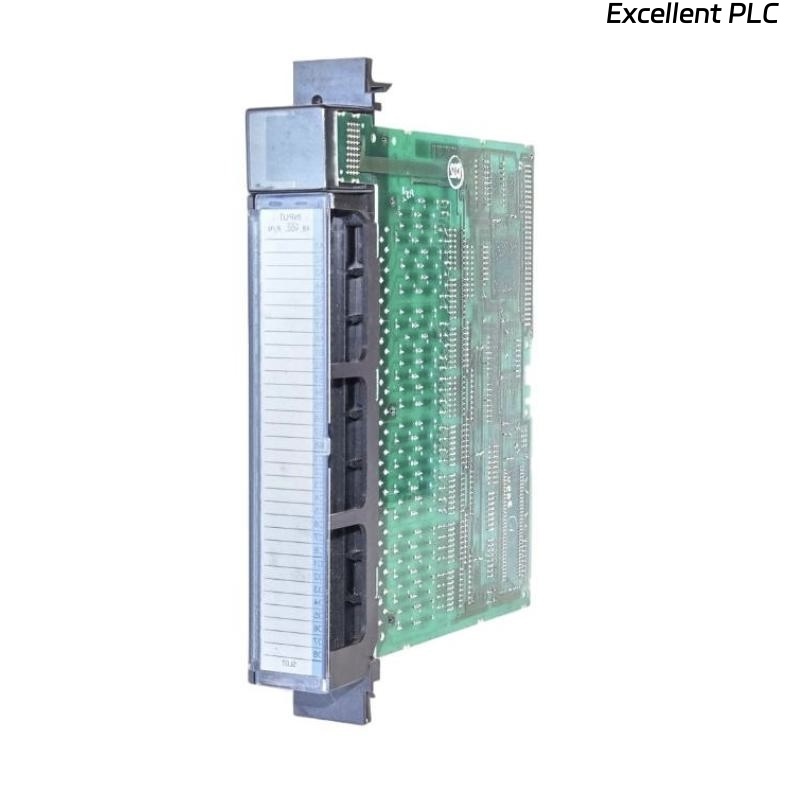

| Mounting Type | DIN Rail |

| Input Voltage | 24 VDC (nominal) |

| Operating Temperature | -40°C to +85°C |

| Protection Type | Turbine Protection |

| Communication | Serial, RS-485 |

| Certifications | CE, UL |

Applications

-

Power plants

-

Industrial machinery and turbines

-

Process control systems requiring high-level protection for rotating equipment

-

Critical infrastructure where turbine integrity is paramount

Advantages

-

Reliable Protection: The module provides continuous monitoring, ensuring that turbine operations remain within safe limits. It triggers protective actions when needed to avoid costly downtime or catastrophic failures.

-

DIN Rail Mounting: This feature allows for quick and easy installation, making it highly adaptable for retrofit projects.

-

High Durability: The module is designed to operate in harsh environments, with a wide operating temperature range and protection against electrical faults.

-

Cost-Effective: It reduces the need for additional turbine protection hardware and integrates seamlessly with existing systems.

-

Flexible Communication: Supports serial communication via RS-485, allowing easy integration with other control systems or SCADA systems for remote monitoring and control.

FAQ

1. What is the purpose of the GE IS230TNTRH1C module?

Answer: The GE IS230TNTRH1C module provides protection for turbine systems, monitoring critical parameters like speed, temperature, and vibration, and triggering protective actions when necessary.

2. How does this module communicate with other systems?

Answer: The module uses RS-485 serial communication to interface with other control systems or SCADA systems for data exchange and remote monitoring.

3. Can the GE IS230TNTRH1C module be installed in a standard control panel?

Answer: Yes, it is designed for DIN rail mounting, which makes it compatible with most control panels that support DIN rail systems.

4. What input voltage does the module require?

Answer: The module operates on a nominal input voltage of 24 VDC.

5. What is the operating temperature range for the GE IS230TNTRH1C module?

Answer: The module is designed to operate in environments with temperatures ranging from -40°C to +85°C.

6. Is the module suitable for use in outdoor or harsh environments?

Answer: Yes, the GE IS230TNTRH1C is built to withstand harsh industrial conditions, including extreme temperatures and electrical noise, making it suitable for outdoor and harsh environments.

7. Does this module support redundancy?

Answer: The IS230TNTRH1C module itself does not feature built-in redundancy, but it can be part of a larger redundant turbine protection system if needed.

8. How is the module calibrated?

Answer: Calibration typically involves configuring the module’s input parameters via the communication interface, allowing it to monitor and protect turbine operations effectively.

9. Can the GE IS230TNTRH1C module handle multiple turbines?

Answer: The module is designed for individual turbine protection, but it can be used in systems with multiple turbines if each unit is equipped with its own module.

10. What certifications does the module have?

Answer: The IS230TNTRH1C module is certified with CE and UL standards, ensuring compliance with international safety and quality standards.

Related Models

| Model | Description | Key Features |

|---|---|---|

| IS230TBAIH1A | Turbine Control Module | Advanced turbine control capabilities |

| IS230TNTRH1A | Turbine Protection Module | Basic protection, simple integration |

| IS230TNRRH1A | Redundant Turbine Protection Module | Offers redundancy for critical applications |

| IS230TNSRH1A | Speed and Vibration Protection Module | Focus on rotor speed and vibration monitoring |

| IS230TPHSH1A | Turbine Protection with Safety Features | Enhanced safety functions for turbine systems |

| IS230TFCBH1A | Turbine Fault Detection Module | Focus on fault detection and mitigation |

Popular Models

| Model | Description | Key Features |

|---|---|---|

| IS210VPRH1A | Vibration Protection Module | Vibration sensing for turbine protection |

| IS220PNIAH1A | Power Supply Protection Module | Essential for power management |

| IS215UCVEM1A | Universal Controller Module | Versatile control unit for turbines |

| IS210BPRH1A | Turbine Protection with Backup Power | Backup power features for enhanced reliability |

| IS220PPDCH1A | Process and Power Distribution Module | Integrated protection and distribution capabilities |

| IS230PSTFH1A | Power System Protection Module | Protection for high-voltage systems |

Excellent PLC

Excellent PLC