| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

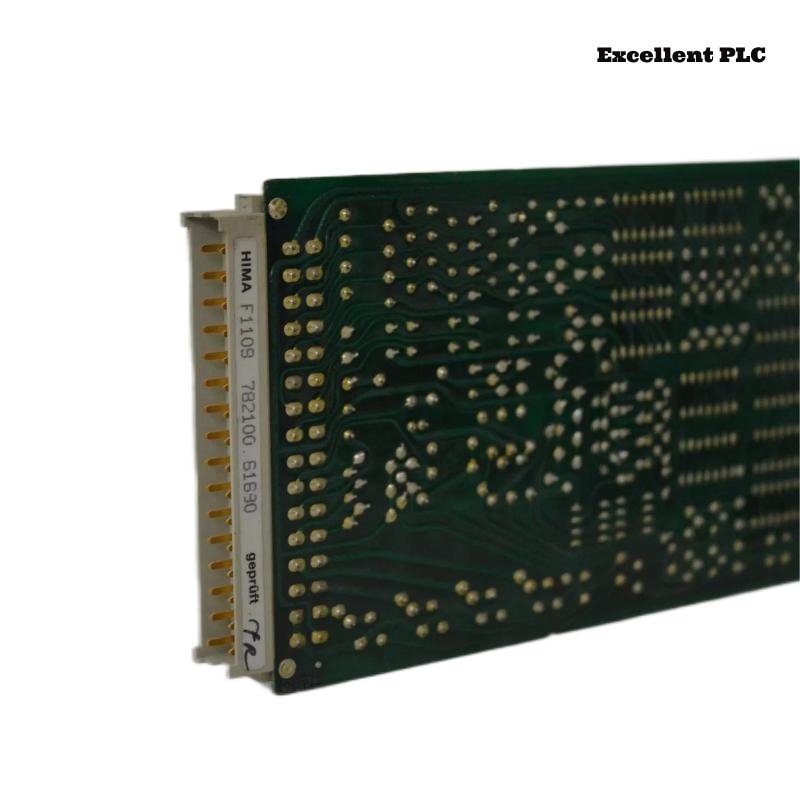

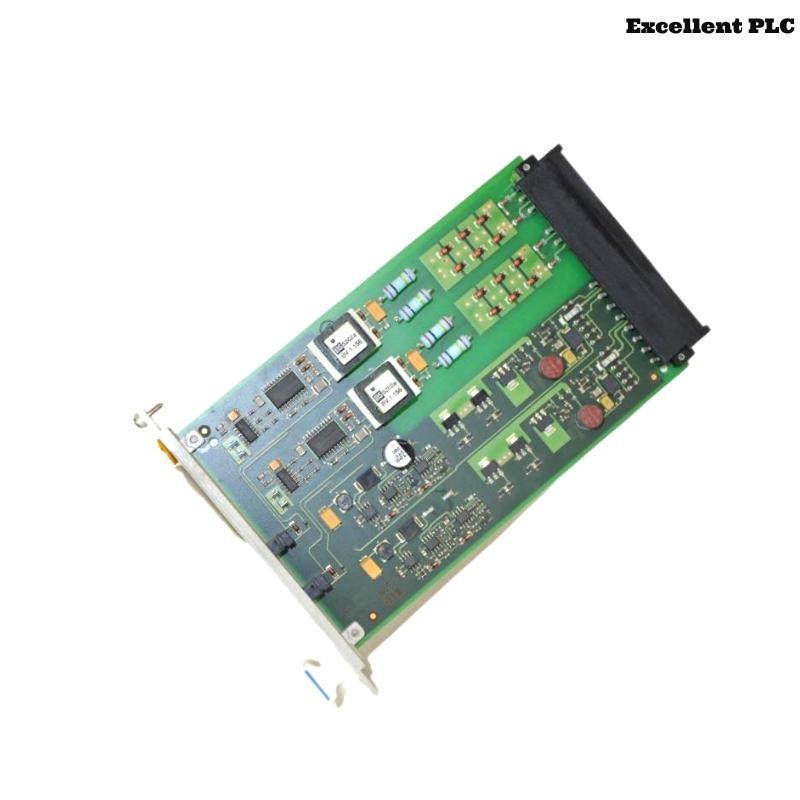

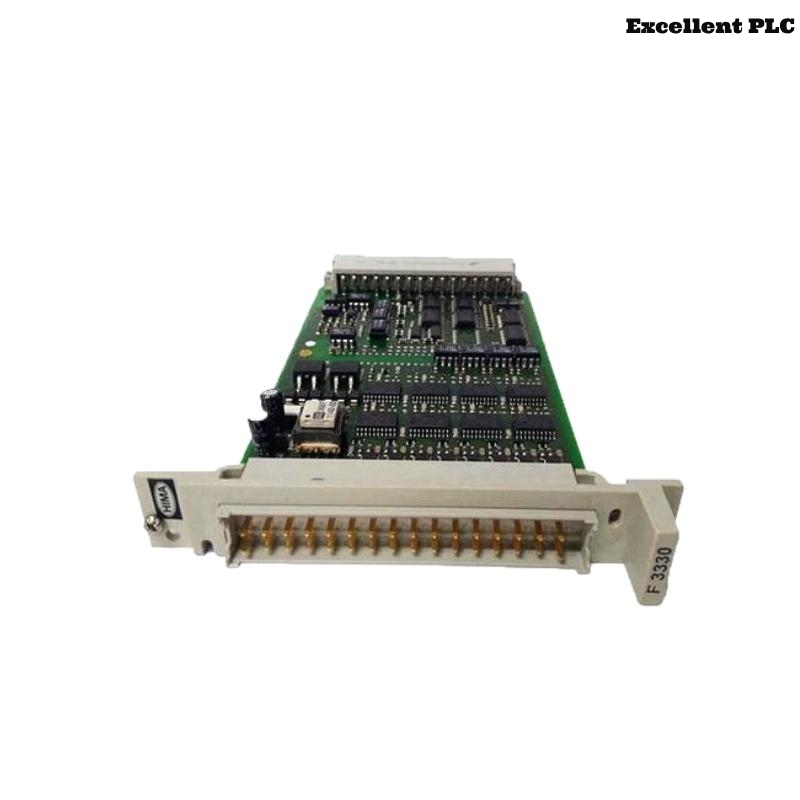

HIMA F1109 Product Overview

The HIMA F1109 is a state-of-the-art safety and control module designed for industrial automation systems requiring high reliability, safety, and redundancy. It is part of the F Series of safety controllers from HIMA, which are renowned for their ability to provide SIL3 (Safety Integrity Level 3) rated protection for critical applications. The F1109 is particularly useful in process industries where ensuring the safety of both people and equipment is crucial.

With its robust design and versatile integration capabilities, the F1109 is suitable for a wide range of industries, including oil and gas, chemical processing, power generation, and more. It helps control and monitor safety-critical operations, making it an ideal choice for systems that require continuous, dependable safety measures.

Product Parameters

| Parameter | Value |

|---|---|

| Model | F1109 |

| Type | Safety and Control Module |

| Safety Level | SIL3 (Safety Integrity Level 3) |

| Input/Output | 16 Digital Inputs, 16 Digital Outputs |

| Power Supply | 24V DC |

| Operating Temp. | -20°C to +60°C |

| Storage Temp. | -40°C to +85°C |

| Dimensions (WxHxD) | 152 x 120 x 75mm |

| Weight | 0.95 kg |

| Enclosure | IP20 |

| Mounting Type | DIN Rail |

| Communication | Ethernet, Modbus, Profibus |

| Approvals | CE, UL, ATEX, IECEx |

Product Applications

The HIMA F1109 is widely used across various sectors where safety-critical operations and compliance with industrial standards are paramount. Key applications include:

- Oil & Gas: The F1109 is crucial in monitoring and controlling safety-critical processes on oil rigs, refineries, and pipelines, helping prevent accidents and equipment failures.

- Power Generation: Used in power plants to monitor and control systems like turbines, generators, and cooling units, ensuring safe and efficient power production.

- Chemical Processing: The F1109 ensures safe operation within chemical plants by offering redundant safety control systems that protect against hazardous events.

- Manufacturing: In automated factories, the F1109 ensures system reliability and safety for processes such as assembly, packaging, and material handling.

- Water and Wastewater Treatment: The module is used to control processes in water treatment facilities, ensuring compliance with safety regulations and providing reliable, continuous operations.

Advantages of HIMA F1109

- High Safety Integrity (SIL3): The F1109 meets the highest safety standards (SIL3), providing a high level of safety for critical processes.

- Redundant Architecture: Built-in redundancy ensures continuous operation even if one part of the system fails, reducing the risk of downtime.

- Compact Design: Despite its advanced functionality, the F1109 offers a compact footprint (152 x 120 x 75mm), making it ideal for applications with space constraints.

- Wide Operating Temperature Range: The system operates efficiently in extreme temperatures, ranging from -20°C to +60°C, making it suitable for diverse environments.

- Versatile Communication: The F1109 supports multiple communication protocols, including Ethernet, Modbus, and Profibus, making it easy to integrate into existing control networks.

- Easy Integration: It is designed for seamless integration with other safety and control systems, enhancing operational flexibility and scalability.

- Advanced Diagnostics: The F1109 includes comprehensive diagnostic features, helping operators detect potential issues early and reduce downtime.

- Compliance with Global Standards: The module is certified for use in various industrial sectors, with approvals such as UL, CE, ATEX, and IECEx.

- Powerful Processing: The F1109 offers high processing power, ensuring that critical safety processes are executed in real-time with minimal delay.

- Energy Efficient: With a low power consumption of 24V DC, the F1109 is energy efficient and cost-effective for continuous operation in industrial environments.

Latest News and Reports

- “HIMA F1109 Enhances Safety in Offshore Oil Platforms” – A feature on how the F1109 is being deployed in offshore oil platforms to ensure the safety of personnel and equipment.

- “HIMA F1109 Set to Revolutionize Safety in Chemical Plants” – An article exploring the F1109’s role in improving safety and compliance in chemical processing environments.

- “Ensuring Power Plant Safety with HIMA F1109” – Discussing how the F1109 enhances operational reliability and safety in power plants around the world.

- “HIMA F1109: A Critical Component in Modern Automation Systems” – Highlighting the growing importance of the F1109 in the automation and control systems of industrial plants.

- “F1109: The Future of Safe Process Automation” – An in-depth look at how HIMA’s F1109 meets the demands for more secure and fault-tolerant control systems in the modern industrial era.

Frequently Asked Questions (FAQs)

-

What is the safety level of the HIMA F1109?

- The HIMA F1109 is certified for SIL3 (Safety Integrity Level 3), which ensures the highest safety standards for critical applications.

-

What is the power supply requirement for the F1109?

- The F1109 operates with a 24V DC power supply.

-

How many inputs and outputs does the F1109 support?

- The F1109 supports 16 digital inputs and 16 digital outputs.

-

What is the operating temperature range for the F1109?

- The operating temperature range is from -20°C to +60°C.

-

Is the HIMA F1109 suitable for hazardous environments?

- Yes, the F1109 is approved for use in hazardous environments with certifications such as ATEX and IECEx.

-

What communication protocols does the F1109 support?

- The F1109 supports Ethernet, Modbus, and Profibus communication protocols.

-

How can the F1109 be integrated into existing systems?

- The F1109 is designed to easily integrate with other control and safety systems, making it suitable for both new installations and retrofits.

-

What is the weight of the HIMA F1109?

- The F1109 weighs 0.95 kg.

-

What are the mounting options for the F1109?

- The F1109 can be mounted on a DIN rail for easy installation.

-

Is the F1109 suitable for use in industrial automation applications?

- Yes, the F1109 is ideal for a wide range of industrial automation applications, including power generation, oil and gas, and chemical processing.

Recommended Models from the HIMA F Series

| Model | Description |

|---|---|

| F1110 | Safety control module with advanced diagnostics |

| F1200 | Compact safety and control processor for small systems |

| F1108 | Modular I/O safety system for process control |

| F1111 | Redundant safety controller for high-risk applications |

| F1209 | High-performance safety processor for automation |

| F1120 | Real-time safety control system for critical processes |

| F1105 | Integrated safety I/O module with diagnostics |

| F1210 | High-integrity safety processor for complex systems |

| F1150 | Multi-channel control processor for industrial automation |

| F1130 | Scalable safety and control module for large installations |

Popular Models from HIMA

| Model | Description |

|---|---|

| HIMAX | High-performance safety and automation system |

| F3000 | Safety controller for large industrial applications |

| F7000 | Modular control system for automation and safety |

| F5500 | Multi-functional safety processor for critical systems |

| F6000 | Advanced safety I/O module for hazardous areas |

| F8000 | Integrated safety system for process automation |

| F1000 | Entry-level safety controller for small-scale applications |

| F9600 | Modular controller with redundant capabilities |

| F9100 | Scalable safety control system for industrial environments |

| F9200 | Real-time control and monitoring system for critical operations |

Excellent PLC

Excellent PLC