| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

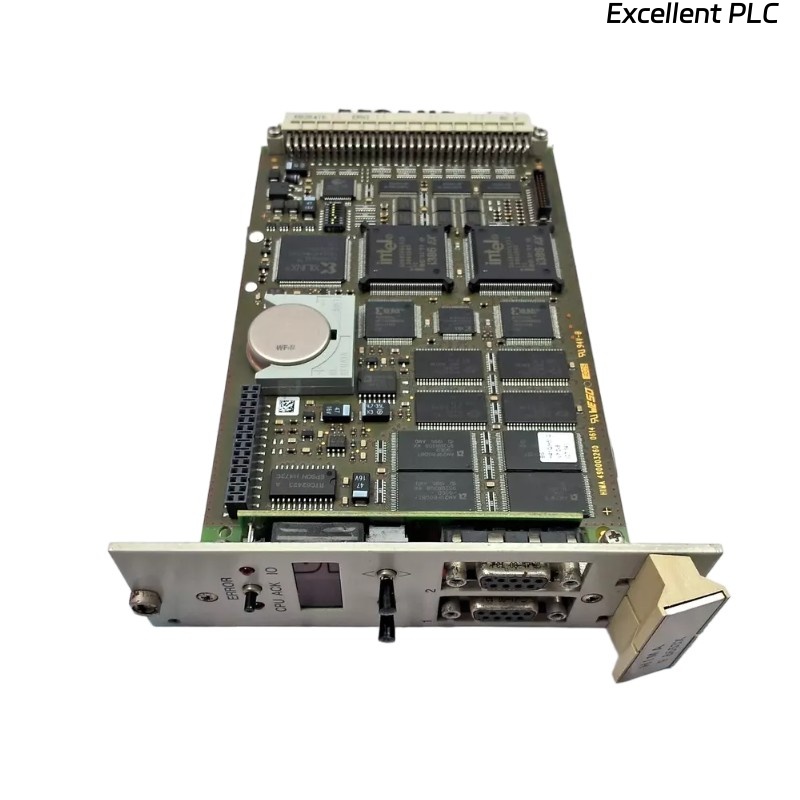

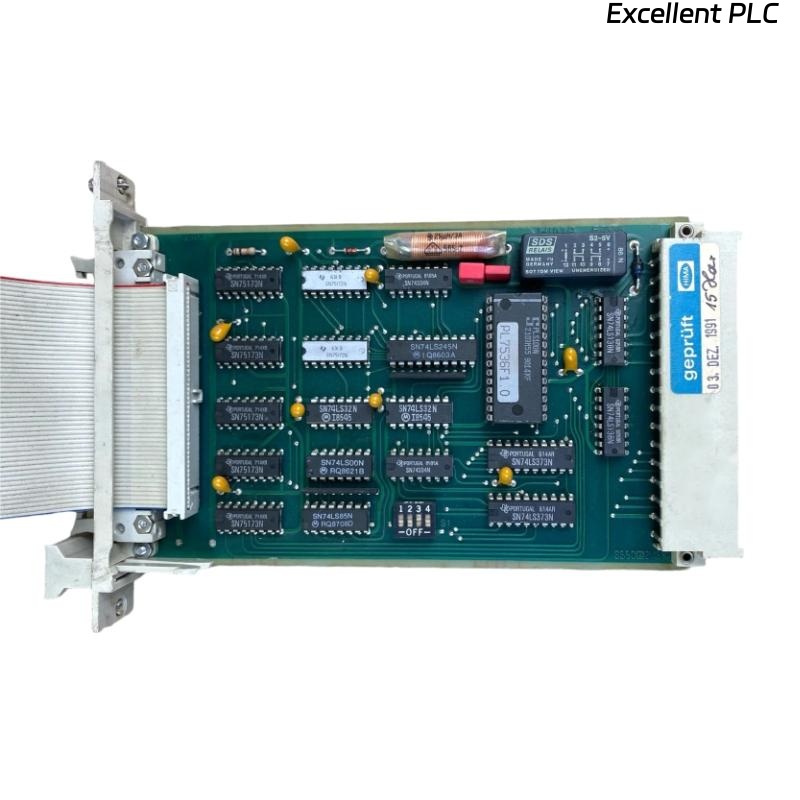

HIMA F1201 Product Overview

The HIMA F1201 is a highly advanced safety controller designed for critical industrial automation applications that require high reliability, fault tolerance, and compliance with international safety standards. As part of the F-Series from HIMA, the F1201 offers Safety Integrity Level (SIL3) certification, ensuring that it can operate in high-risk environments while maintaining the safety of processes and systems.

The F1201 is designed to handle complex safety functions with redundancy and fault detection capabilities, making it ideal for industries such as oil and gas, power generation, chemical processing, and manufacturing. With its scalable architecture and versatile input/output options, the F1201 provides a robust platform for automation systems that need to minimize risk and optimize performance.

Product Parameters

| Parameter | Value |

|---|---|

| Model | F1201 |

| Type | Safety Controller |

| Safety Level | SIL3 (Safety Integrity Level 3) |

| Input/Output | 8 Digital Inputs, 8 Digital Outputs |

| Power Supply | 24V DC |

| Operating Temp. | -20°C to +60°C |

| Storage Temp. | -40°C to +85°C |

| Dimensions (WxHxD) | 152 x 120 x 75 mm |

| Weight | 1.2 kg |

| Enclosure | IP20 |

| Mounting Type | DIN Rail |

| Communication | Ethernet, Modbus, Profibus |

| Approvals | CE, UL, ATEX, IECEx |

Product Applications

The HIMA F1201 is a versatile safety controller that finds applications across various industrial sectors that prioritize safety and operational continuity. Some of the key industries and applications include:

- Oil & Gas: Ensures the safety of complex drilling and refining processes by controlling emergency shutdown systems and managing hazardous equipment with redundancy features.

- Power Generation: Ideal for controlling safety-critical systems such as turbine protection, generator control, and backup safety systems in power plants.

- Chemical Processing: The F1201 controls and monitors processes in chemical plants, helping to prevent dangerous chemical reactions or spills by ensuring failsafe operations.

- Manufacturing: Used in factory automation for processes like material handling, packaging, and assembly, ensuring safety during the operation of robotic arms, conveyors, and other automated equipment.

- Water and Wastewater Treatment: Helps ensure the continuous, safe operation of treatment plants, monitoring critical parameters such as water flow, pressure, and chemical dosing systems.

Advantages of HIMA F1201

- High Safety Integrity (SIL3): Certified for SIL3, the F1201 is capable of safeguarding critical processes and reducing risks in high-hazard applications.

- Redundant Design: Offers built-in redundancy to ensure continuous, reliable operation, even in the event of a component failure, minimizing downtime.

- Compact and Flexible: Despite its high-performance capabilities, the F1201 features a compact design (152 x 120 x 75 mm) and is easy to integrate into existing systems, offering flexibility in both small and large installations.

- Wide Operating Temperature Range: Operates in temperatures ranging from -20°C to +60°C, making it suitable for diverse environments and outdoor installations.

- Multiple Communication Options: With support for Ethernet, Modbus, and Profibus, the F1201 ensures easy integration with other control and safety systems, facilitating seamless operation across different platforms.

- Easy to Install and Maintain: The F1201 can be mounted on a DIN rail and features user-friendly diagnostics, simplifying installation and maintenance.

- Real-time Performance: Ensures fast response times in critical situations, which is vital in environments where timely intervention is necessary for system safety.

- Energy Efficient: Operating on a 24V DC power supply, the F1201 is energy-efficient and cost-effective, helping to reduce operating costs.

- Comprehensive Safety Features: The F1201 offers features such as self-monitoring, diagnostics, and fault detection, which provide an additional layer of protection against system failures.

- Industry Certifications: The F1201 meets multiple safety and quality standards, including CE, UL, ATEX, and IECEx, ensuring its compliance with global regulations for industrial safety.

Latest News and Reports

- “HIMA F1201: A Game Changer for Oil and Gas Industry Safety” – A report on how the F1201 is being deployed in offshore oil rigs to enhance operational safety and reduce risks.

- “Ensuring Safe Power Generation with HIMA F1201” – How the F1201 is improving safety in power plants by managing critical systems like turbine shutdowns and backup safety.

- “Chemical Plants Upgrade Safety with HIMA F1201” – A focus on how the F1201 helps chemical processing plants meet the latest safety standards while improving operational reliability.

- “F1201: A Reliable Solution for Wastewater Treatment Facilities” – A look at how the F1201 is being utilized to monitor and control critical water treatment processes.

- “HIMA F1201: The Next Evolution in Safety Controllers” – A detailed article discussing the advanced features of the F1201 and its role in the future of industrial automation.

Frequently Asked Questions (FAQs)

-

What is the safety level of the HIMA F1201?

- The F1201 is certified for SIL3, ensuring it meets the highest safety integrity standards for critical applications.

-

How many inputs and outputs does the HIMA F1201 have?

- The F1201 supports 8 digital inputs and 8 digital outputs.

-

What is the operating temperature range of the F1201?

- The F1201 operates within a temperature range of -20°C to +60°C.

-

What communication protocols does the F1201 support?

- The F1201 supports Ethernet, Modbus, and Profibus communication protocols.

-

What is the power supply requirement for the F1201?

- The F1201 operates on a 24V DC power supply.

-

Can the F1201 be used in hazardous environments?

- Yes, the F1201 is certified for use in hazardous environments with approvals such as ATEX and IECEx.

-

What is the weight of the HIMA F1201?

- The F1201 weighs 1.2 kg.

-

How can I mount the F1201?

- The F1201 can be easily mounted on a DIN rail for efficient installation.

-

Is the F1201 suitable for large industrial plants?

- Yes, the F1201 is ideal for large industrial applications that require high safety integrity and system redundancy.

-

What industries can benefit from using the F1201?

- The F1201 is used in various industries, including oil and gas, power generation, chemical processing, manufacturing, and water treatment.

Recommended Models from the HIMA F Series

| Model | Description |

|---|---|

| F1202 | Advanced safety control module for high-risk processes |

| F1210 | Scalable safety controller for large installations |

| F1301 | High-performance controller for complex systems |

| F1203 | Multi-channel controller for industrial automation |

| F1108 | Compact safety and control module for small systems |

| F1200 | Safety processor with integrated diagnostics |

| F1211 | Redundant control module for continuous safety |

| F1120 | Real-time control system for critical applications |

| F1109 | Modular controller for flexible safety and control |

| F1300 | High-availability controller for mission-critical operations |

Popular Models from HIMA

| Model | Description |

|---|---|

| F3000 | Advanced safety controller for large-scale industries |

| F7000 | Modular safety system for complex applications |

| F9100 | Real-time safety control module for power plants |

| F8000 | Multi-functional I/O system for industrial safety |

| F5500 | High-integrity safety processor for critical processes |

| F5000 | Integrated safety system for manufacturing plants |

| F6000 | High-availability safety controller for large setups |

| F9100 | Scalable safety control for automation systems |

| F1000 | Basic safety processor for small applications |

| F4000 | Compact I/O system with enhanced safety features |

Excellent PLC

Excellent PLC